7 Ideas for Small-Scale Sugar Bush Operations for Small Acreage

Transform your woodlot into profit with 7 smart strategies for small-scale maple syrup operations. Learn tree selection, equipment, marketing & more.

Why it matters: Starting a small-scale sugar bush operation lets you tap into the growing demand for local maple syrup while creating a sustainable income stream from your woodlot.

The big picture: You don’t need hundreds of acres to succeed – small operations with 50-200 taps can be profitable with the right approach and efficient systems.

What’s next: Smart planning and strategic implementation of proven techniques will help you maximize your sap collection and syrup production without breaking the bank.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Start With Native Sugar Maple Selection and Assessment

Your sugar bush’s foundation starts with selecting the right trees. Quality maple selection directly impacts both sap volume and syrup sweetness for years to come.

Identify Mature Sugar Maple Trees on Your Property

Get a head start on a beautiful landscape with this live American Red Maple tree. This 2-3 foot tall bare root plant thrives in zones 3-9 with full sun and is shipped double boxed for safe arrival.

Look for trees with compound leaves featuring five pointed lobes and smooth gray bark on younger specimens. Mature sugar maples develop characteristic furrowed bark with vertical ridges. You’ll find them thriving in well-drained soils on north-facing slopes where they maintain consistent moisture without waterlogging during spring thaw.

Evaluate Tree Health and Diameter Requirements

Trees need at least 10 inches diameter at chest height before tapping safely. Healthy maples show full crown development with minimal dead branches and no visible decay or pest damage. One tap works for 10-20 inch trees, while specimens over 20 inches can handle two taps without compromising long-term health.

Map Your Sugar Bush Layout for Optimal Tapping

Create a simple sketch showing tree locations, diameters, and natural collection routes. Mark elevation changes and plan your tubing or bucket collection path to minimize walking distance during daily sap runs. Consider prevailing winds and sun exposure since south-facing trees typically start flowing earlier in the season.

Implement Gravity-Fed Collection Systems

Gravity-fed systems revolutionize sap collection by eliminating the daily bucket runs that consume hours of your time. You’ll cut collection labor by 75% while increasing sap yield through continuous flow.

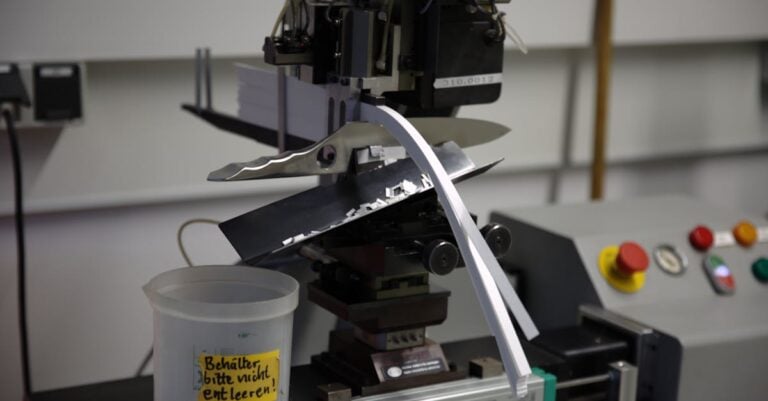

Install Tubing Networks for Efficient Sap Flow

Run 5/16-inch tubing from each tap to larger mainlines, creating a network that carries sap directly to your collection point. Connect 10-15 taps per lateral line, then join these to a 3/4-inch mainline that slopes toward your storage tank. Use proper fittings and tees to prevent leaks that reduce vacuum and contaminate your sap.

Design Sloped Collection Routes to Central Tanks

Plan your mainline routes with a minimum 2% grade to maintain steady sap flow without pumps or electricity. Map your sugar bush elevation changes and position collection tanks at the lowest accessible point. Install check valves at key junctions to prevent backflow during temperature swings that could spoil your entire day’s collection.

Maintain Proper Tubing Sanitization Practices

Clean your entire tubing system with food-grade sanitizer before each season and replace damaged sections immediately. Flush lines weekly during production with fresh water to remove bacteria buildup that creates off-flavors in your syrup. Replace tubing every 3-4 years or when you notice reduced sap flow and discoloration that indicates biofilm formation.

Keep your hands clean and moisturized with Germ-X Advanced Hand Sanitizer. This fast-acting gel kills 99.99% of germs and is enriched with Aloe and Vitamin E to leave your skin feeling soft.

Invest in Small-Batch Evaporation Equipment

Quality evaporation equipment transforms your sugar bush from a hobby into a legitimate operation. You’ll need reliable gear that matches your production scale without breaking the budget.

Choose Between Flat Pan and Arch Evaporators

Flat pan evaporators work perfectly for operations under 100 taps and cost significantly less upfront. You’ll spend 2-3 hours per gallon of syrup but maintain complete control over the process.

Arch evaporators handle larger volumes efficiently and reduce boiling time by 50%. They’re worth the investment if you’re tapping 150+ trees annually.

Calculate Fuel Requirements for Your Operation Size

Plan on burning one cord of seasoned hardwood for every 30-40 gallons of syrup you produce. Split your wood 12-18 months ahead to ensure proper moisture content below 20%.

Track your fuel consumption during your first season to establish baseline costs. Most small operations spend $200-400 annually on quality firewood.

Set Up Proper Ventilation and Safety Systems

Install a hood system that removes steam at twice the evaporation rate to prevent condensation damage. Poor ventilation turns your sugar house into a humid mess within hours.

Position fire extinguishers within 10 feet of your evaporator and maintain clear exit paths. Keep water sources accessible and test all safety equipment before each season starts.

Develop Value-Added Maple Products Beyond Syrup

Your maple syrup operation becomes significantly more profitable when you diversify beyond liquid gold. Value-added products can double or triple your revenue per gallon of sap while extending your selling season year-round.

Create Maple Candy and Cream Specialties

Maple candy and cream offer the highest profit margins in your product lineup. You’ll need to heat syrup to 235-240°F and stir vigorously while cooling to achieve the proper crystallization. Start with small batches of 2-3 cups until you master the temperature control and timing for consistent results.

Produce Maple Sugar and Granulated Products

Maple sugar provides excellent shelf stability and commands premium prices at farmers markets. Heat your syrup to 260°F then stir continuously until it becomes granular and dry. You’ll get roughly 8 pounds of maple sugar from one gallon of syrup while creating a product that stores indefinitely.

Craft Maple-Infused Baked Goods and Treats

Maple cookies, fudge, and barbecue sauces extend your market reach beyond traditional syrup buyers. These products require minimal additional equipment and use lower-grade syrup that might not sell well on its own. Focus on 3-4 signature items rather than overwhelming yourself with too many product lines initially.

Establish Direct-to-Consumer Marketing Channels

Creating direct connections with customers maximizes your profit margins and builds loyalty that sustains your small-scale operation through seasonal fluctuations.

Build Farm Stand and On-Site Sales Opportunities

Setting up an on-site sales presence transforms your sugar house into a destination. A simple farm stand near your operation lets customers see where their syrup comes from, which justifies premium pricing.

Install clear signage on nearby roads and create a small parking area for easy access. Stock your stand with various bottle sizes, value-added products, and seasonal offerings like maple cream during peak tourist seasons.

Develop Online Presence and E-Commerce Platforms

Your digital storefront works 24/7 to capture sales beyond your local area. Start with a simple website featuring high-quality photos of your products and the maple-making process.

Use platforms like Square or Shopify for easy payment processing and shipping management. Focus on telling your story through social media posts showing tapping, boiling, and finished products to build customer connection.

Participate in Local Farmers Markets and Events

Farmers markets provide consistent weekly income and direct customer feedback. Choose markets with strong foot traffic and customers willing to pay premium prices for local products.

Bring samples for tasting, educational materials about maple production, and attractive product displays. Build relationships with other vendors for cross-promotion opportunities and consider seasonal festivals where maple products command higher prices.

Create Agritourism Experiences Around Maple Season

Maple season offers unique opportunities to generate additional revenue streams while educating visitors about traditional syrup-making processes. You’ll find that hosting visitors during peak sap flow creates memorable experiences that command premium pricing.

Offer Educational Sugar Bush Tours and Demonstrations

Tours showcase your tapping process and equipment while building customer connections to your operation. You can charge $10-15 per adult for guided walks through your sugar bush during active sap collection periods.

Demonstrate tapping techniques on mature maples and explain sap flow conditions. Point out different collection methods from buckets to tubing systems. Share stories about weather patterns and daily sap yields to engage visitors with authentic maple-making knowledge.

Host Maple Syrup Making Workshops and Classes

Enjoy the strong, hearty maple flavor of Butternut Mountain Farm's Grade A Dark Color, Robust Taste syrup, perfect for both tabletop use and cooking. This 100% pure Vermont maple syrup is sustainably sourced and Non-GMO Project Verified.

Hands-on workshops teach participants the complete syrup-making process from sap to finished product. You’ll generate $25-40 per person while creating loyal customers who understand your product’s value.

Set up small-batch evaporation demonstrations using your flat pan or arch system. Allow participants to test sap density and monitor temperature during boiling. Include tasting sessions comparing different syrup grades and discuss proper storage techniques for homemade syrup.

Organize Pancake Breakfast Events During Peak Season

Weekend breakfast events combine fresh syrup with community dining experiences that attract repeat visitors. You can serve 50-100 people per event while showcasing multiple maple products in an authentic farm setting.

Partner with local vendors for pancake mix and coffee service to reduce preparation time. Feature your various syrup grades alongside maple cream and candy products. Schedule events during peak sap flow weekends when visitors can observe active collection and boiling operations.

Form Cooperative Partnerships With Other Small Producers

You’ll multiply your sugar bush operation’s potential by joining forces with nearby maple producers. Partnerships turn individual weaknesses into collective strengths while reducing costs and expanding market reach.

Share Processing Equipment and Facilities

Equipment sharing cuts your capital investment by thousands while ensuring you’re not stuck with unused gear after the season. Three or four producers can split costs on expensive evaporators, reverse osmosis systems, and bottling equipment that would otherwise sit idle 10 months yearly. You’ll coordinate schedules based on sap flow timing and production volumes.

Coordinate Marketing Efforts and Bulk Sales

Joint marketing creates professional presence that individual small producers can’t achieve alone. You’ll pool resources for shared websites, coordinated farmers market booths, and bulk orders to restaurants and retailers who prefer dealing with consistent suppliers. Combined volumes unlock wholesale pricing tiers and reduce individual delivery costs significantly.

Exchange Knowledge and Best Practices

Knowledge sharing accelerates your learning curve beyond what trial-and-error alone provides. Experienced partners share tubing layout tricks, troubleshoot equipment problems, and reveal timing secrets for optimal sap collection. You’ll benchmark production rates, compare fuel efficiency strategies, and collectively solve seasonal challenges that would stump individual operators.

Conclusion

Your small-scale sugar bush operation represents more than just a business opportunity—it’s your pathway to creating a sustainable income stream from your woodland property. With the right combination of efficient collection systems quality equipment and strategic marketing you’ll transform your passion for maple syrup into a profitable venture.

The beauty of starting small lies in your ability to grow organically while maintaining quality control over every aspect of production. Whether you’re focusing on premium syrup direct sales or expanding into value-added products and agritourism your operation can adapt to market demands and seasonal opportunities.

Remember that success in maple syrup production comes from consistent execution of proven strategies rather than complex innovations. By implementing these seven ideas systematically you’ll build a foundation for long-term profitability while contributing to your local food economy and preserving traditional maple-making craftsmanship.

Frequently Asked Questions

How many trees do I need to start a profitable maple syrup operation?

You can start a profitable small-scale operation with just 50-200 taps. Success doesn’t require large land areas – even small woodlots can generate sustainable income when managed effectively. Focus on selecting healthy sugar maple trees at least 10 inches in diameter for optimal sap production.

What equipment do I need for maple syrup production?

Essential equipment includes tapping supplies, collection tubing or buckets, and evaporation equipment. For operations under 100 taps, flat pan evaporators work well, while arch evaporators are better for larger volumes. You’ll also need proper ventilation systems and safety equipment in your sugar house.

How much can I reduce labor with a gravity-fed collection system?

A properly designed gravity-fed collection system can reduce labor by up to 75% while enhancing sap yield through continuous flow. The system uses tubing networks that connect taps to mainlines, transporting sap efficiently to collection points without requiring pumps on sloped terrain.

What value-added products can increase my profit margins?

Maple candy, cream, and granulated sugar offer high profit margins beyond traditional syrup. Maple-infused baked goods and treats can broaden your market reach while utilizing lower-grade syrup. These products have excellent shelf stability and can command premium prices at farmers markets.

How can I market my maple products effectively?

Establish direct-to-consumer channels through on-site farm stands, online e-commerce platforms, and social media presence. Participate in local farmers markets for consistent income and customer feedback. Consider agritourism activities like sugar bush tours ($10-15 per adult) and hands-on workshops ($25-40 per person).

What are the benefits of forming cooperative partnerships?

Cooperative partnerships allow small producers to share processing equipment and facilities, reducing costs and capital investment. You can coordinate marketing efforts for bulk sales, achieve professional presence, and unlock wholesale pricing while exchanging knowledge to improve production efficiency and overcome seasonal challenges together.

How do I identify suitable sugar maple trees for tapping?

Look for mature sugar maple trees with distinctive leaves and bark characteristics. Trees must be at least 10 inches in diameter and in good health for optimal sap production. Evaluate tree health carefully and map your sugar bush layout considering factors like elevation, wind, and sun exposure.

What fuel requirements should I plan for maple syrup production?

Calculate fuel requirements based on your production size, using seasoned hardwood for evaporation. Track fuel consumption to establish baseline costs for your operation. Proper planning helps you budget accurately and maintain consistent production throughout the maple season.