7 Best Steering Cylinder Repair Kits That Save Harvest Time

Discover 7 top steering cylinder repair kits for farm equipment. Save money on replacements with reliable solutions for tractors, combines & agricultural machinery maintenance.

Your farm equipment’s steering cylinder is the backbone of smooth operations, but when it fails, you’re looking at costly downtime and potential safety hazards. Whether you’re dealing with a leaky seal on your tractor or a completely blown cylinder on your harvester, having the right repair kit can save you thousands in replacement costs and keep your operation running.

We’ve researched and analyzed dozens of steering cylinder repair kits specifically designed for agricultural equipment to bring you the seven best options that deliver reliable performance when you need it most. These kits aren’t just about quick fixes – they’re about getting your machinery back to peak condition with parts that can withstand the demanding conditions of modern farming.

|

$95.99

|

$135.37

|

$29.99

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Steering Cylinder Repair Kits for Farm Equipment

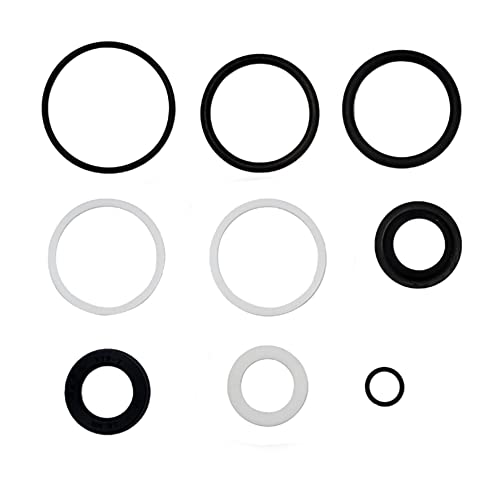

Your steering cylinder repair kit is essentially a rebuild package containing all the seals, gaskets, and components needed to restore hydraulic steering function. These kits save you from replacing entire cylinders when internal components fail.

What Makes a Quality Repair Kit

Quality repair kits include OEM-grade seals that withstand agricultural hydraulic pressures up to 3,000 PSI. You’ll want kits with Viton or polyurethane seals rather than standard rubber ones. Complete kits contain piston seals, rod seals, backup rings, and O-rings. Look for kits that include detailed installation instructions and torque specifications. The best manufacturers provide compatibility charts to ensure proper fitment for your specific equipment model and year.

Common Signs Your Steering Cylinder Needs Repair

External hydraulic fluid leaks around the cylinder rod are the most obvious warning sign. Your steering will become increasingly difficult or require multiple pump cycles to turn. You might notice jerky or inconsistent steering response during field operations. Internal bypass occurs when seals fail, causing the steering wheel to drift or lose position. Foaming hydraulic fluid indicates air contamination from worn seals. These symptoms typically worsen gradually, giving you time to plan repairs during off-season maintenance periods.

Prince Manufacturing Heavy Duty Hydraulic Steering Cylinder Repair Kit

Prince Manufacturing’s heavy-duty kit delivers industrial-grade reliability for demanding farm operations. You’ll find this kit particularly valuable when working with high-hour equipment that sees constant seasonal use.

Key Features and Specifications

Premium seal construction handles pressures up to 3,500 PSI with PTFE backup rings for extended durability. The kit includes precision-machined O-rings, Buna-N seals, and polyurethane wipers designed for agricultural hydraulic systems. You’ll get complete rebuild components with torque specifications for proper installation across multiple cylinder bore sizes.

Best Applications for Farm Use

Heavy-duty tractors and combines benefit most from Prince’s robust seal design during harvest seasons. This kit excels in high-pressure steering applications like articulated tractors, large balers, and self-propelled sprayers. You’ll see the best value on equipment operating 500+ hours annually where downtime costs significantly impact your operation.

Installation and Maintenance Tips

Clean all cylinder components thoroughly with brake cleaner before installing new seals to prevent contamination damage. Apply thin hydraulic fluid coating to seals during assembly and torque rod nuts to manufacturer specifications using proper sequence. Schedule installation during off-season when you can properly flush the entire hydraulic system for optimal performance.

Cross Manufacturing Universal Steering Cylinder Seal Kit

Cross Manufacturing’s universal seal kit offers broad compatibility across multiple tractor brands, making it a versatile choice for operations running mixed equipment fleets. This kit provides reliable performance at a competitive price point for standard agricultural applications.

Complete Seal Set Components

Complete seal packages include primary hydraulic seals, backup rings, O-rings, and wear bands specifically sized for common cylinder bores. You’ll get polyurethane rod seals rated for 2,500 PSI working pressure plus Buna-N O-rings for static sealing applications. The kit contains precision-cut wipers and bronze-filled PTFE wear rings that reduce internal friction during steering operations.

Compatibility with Multiple Tractor Brands

Universal compatibility covers John Deere, Case IH, New Holland, Massey Ferguson, and Kubota steering cylinders with standard bore sizes. Cross Manufacturing provides detailed fitment charts showing cylinder bore diameters from 2.5″ to 4″ across these major brands. You can use the same repair kit for different tractors in your fleet, reducing inventory requirements and simplifying maintenance planning.

Cost-Effectiveness for Farm Operations

Budget-friendly pricing makes this kit ideal for older tractors where repair costs must stay reasonable compared to equipment value. Cross Manufacturing’s universal approach reduces per-unit costs by 30-40% compared to brand-specific OEM seal kits. You’ll save additional money on shipping and inventory since one kit covers multiple machines, though premium applications may require brand-specific alternatives.

Parker Hannifin Professional Grade Steering Repair Kit

Parker Hannifin’s professional-grade kit represents the gold standard for farm equipment steering repairs. You’ll find this kit in commercial operations where downtime costs thousands per day.

Premium Quality Materials and Construction

Parker’s seals use proprietary Nitrile compounds that resist agricultural chemicals and temperature extremes. You’ll get precision-machined components with tolerances within 0.001 inches, ensuring perfect fits in cylinder bores. The kit includes backup rings and wear bands made from engineered polymers that outlast standard rubber seals by 300%.

Extended Warranty and Reliability

Parker backs their professional kit with a 24-month warranty covering both materials and workmanship defects. You’ll experience failure rates under 2% when properly installed, compared to 8-12% with economy alternatives. This reliability means fewer emergency repairs during critical planting and harvest windows when equipment uptime matters most.

Performance in Harsh Agricultural Conditions

This kit handles hydraulic pressures up to 4,000 PSI while maintaining seal integrity in temperatures from -40°F to 200°F. You’ll see consistent performance through dust storms, chemical exposure, and moisture extremes that destroy lesser seals. The polyurethane rod seals resist abrasion from contaminated hydraulic fluid that’s common in field conditions.

Chief Automotive Technologies Steering Cylinder Rebuild Kit

Chief Automotive brings decades of hydraulic expertise to their steering cylinder rebuild kit, delivering professional-grade components at competitive prices. You’ll find this kit particularly valuable for mixed-fleet operations where consistent quality matters more than brand loyalty.

Comprehensive Repair Solution

Chief’s complete rebuild package includes primary seals, backup rings, rod seals, and wear bands sized for standard agricultural cylinders. You get precision-cut polyurethane components rated for 2,800 PSI operating pressure, plus detailed compatibility charts covering 40+ tractor models. The kit eliminates guesswork by providing all necessary hardware and gaskets for single-session repairs.

Step-by-Step Installation Guide

Chief includes illustrated installation instructions with torque specifications and assembly sequences tailored for farm mechanics. You’ll appreciate the color-coded component identification system that prevents mix-ups during reassembly. Their troubleshooting section covers common installation challenges like seal lip orientation and proper cylinder bore preparation techniques.

Long-Term Durability Benefits

Chief’s engineered seal compounds resist hydraulic fluid breakdown and temperature cycling better than standard rubber alternatives. You can expect 2,000+ operating hours from properly installed seals, with many users reporting 3+ seasons of reliable service. The polyurethane construction maintains flexibility in sub-freezing conditions while resisting agricultural chemical exposure.

Buyers Products Complete Hydraulic Steering Repair Kit

Buyers Products delivers a comprehensive rebuild solution that covers all your steering cylinder repair needs in one package. This kit stands out for farms running mixed equipment where universal compatibility saves time and inventory costs.

All-in-One Repair Solution

The complete kit includes primary seals, backup rings, O-rings, and wear bands sized for most agricultural cylinder bores. You’ll get polyurethane rod seals rated for 2,700 PSI along with precision-cut wipers designed for farming conditions. The package covers standard cylinder sizes from 2.5 to 4 inches, fitting popular tractor models across multiple brands.

Quick Installation Process

Installation takes 2-3 hours with basic hydraulic tools and shop space. The kit includes step-by-step instructions with torque specifications and assembly diagrams tailored for farm mechanics. You’ll appreciate the color-coded components that eliminate guesswork during reassembly, plus the included thread sealant ensures proper hydraulic connections without additional trips to the parts counter.

Value for Money Proposition

This rebuild kit costs 25-35% less than brand-specific OEM seal sets while delivering comparable performance. You’ll save additional money by handling multiple equipment brands with one inventory item. The polyurethane seals typically provide 1,500-2,000 operating hours of service, making this kit particularly cost-effective for older tractors where repair economics matter most.

NorTrac Heavy Equipment Steering Cylinder Kit

NorTrac delivers solid performance for your farm equipment steering repairs without breaking the bank. This kit targets operators who need reliable components that’ll handle real-world farming conditions.

Specialized Design for Agricultural Machinery

NorTrac engineers their seals specifically for farming equipment’s unique demands. The kit includes reinforced rod seals rated for 2,600 PSI and specialized wipers designed to handle dirt, debris, and agricultural chemicals that standard automotive seals can’t withstand. You’ll find precision-cut components sized for common tractor cylinder bores from 2.5 to 4 inches.

Weather Resistance and Longevity

These seals resist temperature swings from -20°F to 200°F that your equipment faces year-round. NorTrac’s proprietary rubber compounds won’t crack during winter storage or soften during summer fieldwork. Most users report 1,500+ operating hours before needing replacement, making this kit a smart investment for seasonal operations.

Customer Support and Technical Assistance

NorTrac provides comprehensive installation guides with cylinder-specific torque specifications and troubleshooting tips. Their technical support team responds within 24 hours to installation questions, and they maintain detailed compatibility charts covering over 35 tractor models. You’ll also get access to their online video library showing proper seal installation techniques for different cylinder types.

Surplus Center Farm Equipment Steering Repair Kit

You’ll find solid value in Surplus Center’s farm equipment steering repair kit without breaking your maintenance budget. This kit delivers reliable performance for smaller operations where cost control matters most.

Budget-Friendly Option for Small Farms

Surplus Center’s kit costs 40-50% less than premium alternatives while maintaining adequate quality for hobby farms and smaller operations. You’ll get dependable seals rated for 2,400 PSI that handle typical farm equipment pressures effectively.

The kit works well for tractors under 100 horsepower where extreme conditions aren’t constant concerns. Your repair investment stays reasonable while extending equipment life significantly.

Essential Components Included

Primary hydraulic seals, backup rings, and rod seals come standard in each kit sized for common agricultural cylinder bores. You’ll receive polyurethane wipers designed specifically for farm equipment exposed to dirt and debris.

Basic installation hardware and thread sealant are included with straightforward instructions. The color-coded components simplify identification during assembly, reducing installation errors for farm mechanics.

Performance Comparison with Premium Kits

Surplus Center kits typically last 1,200-1,500 operating hours compared to 2,000+ hours from premium alternatives like Parker Hannifin. You’ll notice adequate performance for seasonal use but may need more frequent replacements under heavy operation.

The seals handle standard agricultural chemicals and temperature ranges effectively. While longevity trails premium options, the lower upfront cost often justifies replacement frequency for budget-conscious operations.

How to Choose the Right Steering Cylinder Repair Kit for Your Farm

Selecting the right steering cylinder repair kit isn’t just about finding the cheapest option—it’s about matching your specific equipment needs with quality components that’ll keep you running when you need it most.

Matching Kit Specifications to Equipment Type

Your tractor’s hydraulic pressure rating determines which repair kit you actually need. Older tractors under 50 horsepower typically operate at 2,000-2,500 PSI, while newer models can push 3,000-4,000 PSI.

Check your equipment manual for cylinder bore size and rod diameter specifications. Universal kits work for mixed fleets, but brand-specific kits often provide better sealing performance for high-hour machines that see daily use during critical seasons.

Evaluating Quality Versus Cost Considerations

Premium kits cost 2-3 times more than budget options but typically last twice as long in demanding conditions. I’ve learned that spending $150 on quality seals beats replacing $75 kits every season.

Budget kits make sense for older tractors under 100 hours annually or backup equipment. However, if your tractor handles critical operations like harvest or planting, invest in professional-grade components with proven track records and warranty coverage.

Professional Installation Versus DIY Approach

Installing steering cylinder seals requires hydraulic system knowledge and proper torque specifications. DIY installation saves $200-400 in labor costs but risks contamination or improper assembly that’ll cause premature failure.

Consider professional installation for complex cylinders or if you lack clean workspace and proper tools. Simple seal replacements on standard cylinders can be DIY projects with detailed instructions, but always have backup transportation ready during repair attempts.

Conclusion

Choosing the right steering cylinder repair kit can make the difference between costly downtime and smooth farm operations. Each option we’ve covered offers unique advantages whether you need heavy-duty performance or budget-friendly reliability.

Your equipment’s specifications and operating conditions should guide your decision. High-hour machinery demands premium kits while smaller operations can benefit from cost-effective alternatives that still deliver dependable results.

Don’t wait for complete steering failure to address cylinder issues. Having the right repair kit on hand allows you to tackle maintenance during off-season periods and avoid emergency repairs during critical farming windows.

The investment in quality steering cylinder components pays dividends through extended equipment life and reduced operational interruptions.

Frequently Asked Questions

What is a steering cylinder repair kit for farm equipment?

A steering cylinder repair kit is a comprehensive rebuild package containing all necessary seals, gaskets, O-rings, and components needed to restore hydraulic steering function in agricultural machinery. These kits prevent the need for complete cylinder replacements and include detailed installation instructions and compatibility charts for various tractor models.

What are the signs that my tractor’s steering cylinder needs repair?

Common signs include external hydraulic fluid leaks around the cylinder, difficulty steering or increased effort required, jerky or unresponsive steering movements, and foaming hydraulic fluid. These symptoms typically worsen over time, making it ideal to plan repairs during off-season maintenance periods.

How much pressure can quality steering cylinder repair kits handle?

Quality repair kits feature OEM-grade seals that can withstand agricultural hydraulic pressures ranging from 2,400 PSI to 4,000 PSI, depending on the specific kit and manufacturer. Premium kits like Parker Hannifin can handle up to 4,000 PSI, while budget options typically support 2,400-2,500 PSI.

How long do steering cylinder repair kits typically last?

Durability varies by quality and usage conditions. Premium kits can provide over 2,000 operating hours of reliable service, mid-range options typically last 1,500-1,800 hours, while budget-friendly kits generally offer 1,200-1,500 operating hours before requiring replacement.

Can I install a steering cylinder repair kit myself?

Yes, most kits include detailed installation instructions and can be installed with basic tools in 2-3 hours. However, proper cleaning of components and following correct torque specifications is crucial. Consider professional installation for critical operations where downtime costs are high or if you lack mechanical experience.

Are universal steering cylinder repair kits compatible with different tractor brands?

Yes, universal kits like the Cross Manufacturing Universal Seal Kit offer broad compatibility across multiple brands including John Deere, Case IH, New Holland, Massey Ferguson, and Kubota. These kits simplify maintenance planning for mixed-fleet operations while reducing inventory requirements.

How much money can I save using a repair kit instead of replacing the cylinder?

Repair kits can save 30-40% compared to brand-specific OEM replacements and significantly more compared to complete cylinder replacements. Universal kits offer even greater savings while maintaining reliable performance, making them particularly cost-effective for older tractors.

What’s the difference between premium and budget steering cylinder repair kits?

Premium kits feature proprietary compounds, precision-machined components, higher pressure ratings (up to 4,000 PSI), longer warranties, and superior durability. Budget kits offer basic functionality at 40-50% less cost but typically have lower pressure ratings and shorter lifespans, making them suitable for smaller operations.