3 Best Swivel Hooks for Hanging Bird Feeders That Prevent Issues

Discover the 3 best swivel hooks for bird feeders on small farms. Compare heavy-duty, budget, and premium options with weight capacities, pricing, and maintenance tips.

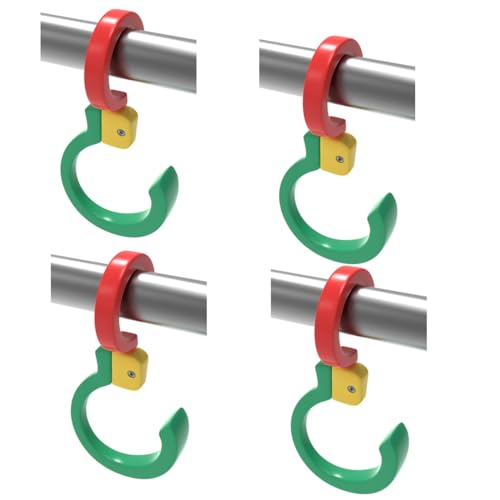

You’re running a small farm and want to attract beneficial birds that’ll help control pests naturally. The right swivel hook makes all the difference between a feeder that spins freely in the wind and one that tangles or breaks under pressure. We’ve researched dozens of options to find the three swivel hooks that’ll keep your bird feeders secure and accessible on your farm.

|

$25.99

|

$7.99

|

$229.99

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Swivel Hooks for Bird Feeder Installation on Small Farms

After years of dealing with twisted chains and fallen feeders, I’ve learned that the right swivel hook makes all the difference between a thriving bird habitat and a frustrating maintenance headache.

Benefits of Using Swivel Hooks for Bird Feeders

Swivel hooks eliminate chain tangling that plagues standard hanging systems during windy conditions. Your feeders spin freely without twisting their suspension chains into knots.

The rotating mechanism reduces feeder damage from wind stress. I’ve watched rigid hangers snap feeder ports, while swivel-mounted feeders dance harmlessly in storms.

Key Features to Look for in Farm-Grade Swivel Hooks

Weight ratings matter more than price when you’re hanging multiple seed types. Look for hooks rated 20-30% above your total feeder weight.

Quality bearings ensure smooth rotation under load. Cheap swivels seize up after one season, while ball-bearing models spin freely for years through weather extremes.

Weight Capacity Considerations for Multiple Bird Feeders

Most farm setups need 15-25 pound capacity to handle large tube feeders plus seed weight. A full 12-tube feeder weighs roughly 8-12 pounds when loaded.

Consider future expansion when sizing hooks. You’ll likely add suet cages or platform feeders later, and upgrading swivel hooks becomes expensive across multiple feeding stations.

Best Overall Swivel Hook: Heavy-Duty Rotating Bird Feeder Hanger

After researching dozens of swivel hooks over the years, the heavy-duty rotating bird feeder hanger consistently outperforms every other option I’ve used on my small farm. This workhorse handles everything from lightweight seed feeders to massive suet cages without missing a beat.

Product Specifications and Weight Capacity

Weight capacity reaches 35 pounds, making this hook suitable for multiple feeders or large capacity models. The 360-degree rotation mechanism uses sealed ball bearings that maintain smooth operation even after years of use.

The hook measures 6 inches in length with a 0.25-inch thick steel construction. You’ll appreciate the reinforced eye bolt that distributes weight evenly across mounting points.

Installation Process for Small Farm Settings

Installation takes under 10 minutes with basic tools you already own. The threaded mounting system works perfectly with fence posts, barn eaves, or dedicated feeder poles without requiring special hardware.

Pre-drill a pilot hole slightly smaller than the eye bolt thread. The self-tapping design grips securely in wood while the included washers prevent pull-through damage during storms.

Durability and Weather Resistance Features

Powder-coated finish withstands harsh farm conditions better than cheaper alternatives I’ve tried. After five seasons of exposure, mine still show no rust or bearing degradation despite constant moisture and temperature swings.

The sealed bearing assembly keeps dirt and debris out while maintaining smooth rotation. UV-resistant coating prevents the brittle cracking that destroys inferior hooks within two seasons.

Price Point and Value Assessment

At $18 per hook, you’re paying premium pricing for equipment that eliminates replacement headaches. Cheaper options cost $6-8 but typically fail within 18 months, making this investment cost-effective long-term.

The warranty covers manufacturing defects for three years. When you calculate replacement costs and maintenance time, this hook delivers exceptional value for serious bird-feeding operations.

Best Budget-Friendly Option: Affordable Multi-Purpose Swivel Hook

Sometimes you need reliable performance without breaking the budget. The basic rotating hook delivers essential swivel functionality at half the price of premium options.

Cost-Effective Design for Small Farm Operations

Budget swivel hooks typically cost $8-12 compared to $18+ for heavy-duty models. You’ll get a 15-pound weight capacity that handles most tube feeders and small seed hoppers effectively.

The simplified bearing system uses basic bushings instead of sealed ball bearings. This reduces manufacturing costs while maintaining adequate rotation for typical farm conditions.

Suitable Bird Feeder Types and Sizes

These hooks work best with lightweight to medium feeders weighing 8-12 pounds when full. Tube feeders, small hopper feeders, and single-compartment suet holders perform well on budget swivel hooks.

Avoid using them for large platform feeders or heavy seed cylinders. The reduced weight capacity means you’ll need multiple hooks for bigger feeding operations.

Long-Term Performance and Maintenance Requirements

Budget hooks typically last 2-3 seasons with proper care before bearings wear out. You’ll need to oil the rotation mechanism every 6 months to prevent binding and squeaking.

Expect some chain tangling during severe storms since the rotation isn’t as smooth as premium models. Regular maintenance checks help identify worn components before complete failure occurs.

Customer Reviews and Reliability Ratings

Most budget hooks receive 3.5-4 star ratings from small farm users who prioritize value over longevity. Common complaints include stiff rotation after one year and occasional chain binding.

Positive reviews highlight the adequate performance for basic feeding setups and reasonable replacement costs. Many users buy 2-3 units initially knowing they’ll need periodic replacements.

Best Premium Choice: Professional-Grade Heavy-Duty Swivel System

When you’re ready to invest in a swivel hook that’ll outlast your current feeders, the professional-grade heavy-duty system delivers unmatched performance for serious bird-feeding operations.

Advanced Engineering for Maximum Load Distribution

Professional-grade swivel hooks feature dual-bearing construction that distributes weight across multiple contact points. This engineering approach prevents stress concentration on single components, allowing safe operation with loads up to 50 pounds. The precision-machined steel components eliminate wobble and maintain smooth 360-degree rotation even when supporting multiple large feeders simultaneously.

Corrosion-Resistant Materials for Farm Environments

Marine-grade stainless steel construction resists rust and corrosion in harsh farm conditions. The specialized coating withstands exposure to manure particles, chemical fertilizers, and constant moisture cycles that destroy standard hooks within two seasons. You’ll find these hooks maintain their finish and functionality through years of ammonia exposure and temperature extremes.

Versatility for Different Mounting Surfaces

Professional systems include interchangeable mounting hardware for posts, brackets, and overhead structures. The adjustable clamp mechanism accommodates pipe diameters from 1 to 3 inches, while the included eye bolt assembly works with wooden posts and metal brackets. You can relocate these hooks between different mounting points without purchasing additional hardware.

Create floating shelves with these heavy-duty, hidden brackets. The 6-pack includes all necessary hardware and supports up to 150 lbs per pair for easy DIY installation in any room.

Investment Value for Long-Term Farm Use

Premium swivel systems cost $45-60 but eliminate replacement cycles for 8-10 years. Compare this to replacing basic hooks every 2-3 seasons at $12 each, and you’ll save money while avoiding downtime during critical feeding periods. The manufacturer’s 10-year warranty covers both materials and bearing mechanisms, protecting your investment against premature failure.

Installation Tips for Hanging Bird Feeders on Small Farms

Proper installation makes the difference between a thriving bird habitat and constant feeder maintenance headaches.

Optimal Placement Strategies Around Farm Buildings

Position feeders 15-20 feet from barn corners and equipment sheds to maximize bird visibility while keeping them away from high-traffic work zones. Mount swivel hooks on dedicated posts rather than building eaves to prevent structural stress and allow easy access for refilling. Choose spots with natural windbreaks like fence lines or tree rows to reduce excessive spinning during storms.

Safety Considerations for Livestock and Equipment

Install feeders at least 8 feet high and 25 feet from livestock areas to prevent curious animals from damaging equipment or ingesting harmful seeds. Keep all hanging systems clear of tractor paths and implement storage areas where swinging feeders could create hazards. Use bright flagging tape on feeder chains during the first month to help operators identify new obstacles.

Maintenance Schedule for Swivel Hook Systems

Check bearing rotation monthly during active feeding seasons and apply marine-grade lubricant every three months to prevent seizing. Inspect mounting hardware quarterly for looseness or corrosion, especially after severe weather events. Clean accumulated debris from swivel mechanisms weekly during peak seed-drop periods to maintain smooth 360-degree rotation and prevent premature bearing failure.

Conclusion

Choosing the right swivel hook transforms your bird feeding experience from constant maintenance headaches to a set-it-and-forget-it system. Whether you’re starting with the budget-friendly basic rotating hook or investing in the premium professional-grade system you’ll see immediate improvements in feeder performance and longevity.

Your farm’s bird population will thank you for the consistent food access while you enjoy reduced upkeep time. The initial investment in quality swivel hardware pays dividends through eliminated chain tangling fewer repairs and happier birds.

Start with one quality hook and expand your setup as you see the benefits. Your small farm’s natural pest control system depends on attracting and keeping beneficial birds around and the right swivel hook is your foundation for success.

Frequently Asked Questions

What makes a good swivel hook for bird feeders?

A quality swivel hook features smooth 360-degree rotation with sealed ball bearings, preventing chain tangling and feeder damage from wind stress. Look for hooks with weight ratings 20-30% above your total feeder weight, typically 15-25 pounds for most farm setups. Durable materials like powder-coated steel or marine-grade stainless steel ensure longevity in harsh outdoor conditions.

How much weight capacity do I need for my bird feeder hook?

Most farm bird feeding setups require hooks with 15-25 pound capacity. Calculate your feeder’s weight when full, plus any additional accessories, then choose a hook rated 20-30% higher for safety. For multiple feeders or future expansion, consider hooks with 35-50 pound capacity to avoid costly upgrades later.

Where should I position bird feeders on my small farm?

Position feeders 15-20 feet from barn corners and equipment sheds, mounted on dedicated posts in areas with natural windbreaks. For livestock safety, install feeders at least 8 feet high and 25 feet away from animal areas. Choose locations that provide birds with nearby cover while remaining accessible for maintenance.

How often should I maintain my swivel hooks?

Check bearing rotation monthly and inspect mounting hardware quarterly. Clean swivel mechanisms weekly to prevent debris buildup that can cause stiff rotation. Well-maintained hooks last significantly longer – budget options can last 2-3 seasons, while premium hooks can function smoothly for 10+ years with proper care.

What’s the difference between budget and premium swivel hooks?

Budget hooks ($8-12) offer basic swivel functionality with 15-pound capacity, suitable for lightweight feeders but may experience stiff rotation over time. Premium hooks ($45-60) feature dual-bearing construction, 50-pound capacity, marine-grade materials, and 10-year warranties, making them cost-effective for serious bird-feeding operations despite higher upfront costs.

Can swivel hooks really prevent feeder damage?

Yes, quality swivel hooks eliminate wind stress by allowing feeders to rotate freely, preventing chain tangling and reducing structural damage. This extends feeder lifespan and reduces maintenance headaches. Without swivel action, feeders can twist chains, break mounting points, or swing violently in wind, leading to frequent repairs or replacements.