3 Best Insulated Composite Toe Boots for Winter Barn Work That Last

Discover the 3 best insulated composite toe boots for winter barn work. Stay warm, safe & comfortable during cold weather chores with our expert picks.

Winter barn work demands boots that can handle freezing temperatures wet conditions and heavy-duty tasks without compromising your safety or comfort. You need footwear that’ll protect your feet from crushing hazards while keeping them warm during those early morning chores and late evening feed runs. The right insulated composite toe boots make all the difference between a productive day and one spent dealing with cold wet feet that slow you down.

Finding boots that balance warmth protection and durability isn’t easy when you’re working around livestock and heavy equipment. You’ll want composite toe protection that won’t conduct cold like steel toes do plus insulation that actually works in sub-freezing temperatures. The best winter barn boots combine waterproof construction slip-resistant soles and materials that can withstand the harsh realities of agricultural work.

|

$189.99

|

$124.95

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding the Importance of Insulated Composite Toe Boots for Winter Barn Work

Working through winter months demands boots that handle both safety hazards and brutal cold conditions. Your feet face crushing dangers from livestock and equipment while battling freezing temperatures that can cause frostbite in minutes.

Protection Against Cold Weather Hazards

Insulated boots prevent frostbite during pre-dawn chores when temperatures drop below freezing. Quality insulation maintains warmth even when standing in snow or wet bedding for extended periods. Cold feet reduce your dexterity and reaction time, creating dangerous situations around unpredictable animals and machinery.

Safety Benefits of Composite Toe Construction

Composite toes don’t conduct cold like steel does, keeping your toes warm while providing ASTM-rated protection. They’re lighter than steel alternatives, reducing fatigue during long work days. Composite materials won’t trigger metal detectors and provide electrical hazard protection when working around farm equipment.

Durability Requirements for Farm Environment

Farm environments destroy inferior boots within months through constant exposure to manure, chemicals, and rough surfaces. Quality construction withstands daily cleaning with pressure washers and harsh disinfectants. Reinforced seams and puncture-resistant soles handle sharp objects like nails, wire, and metal debris scattered around barnyards.

This electric pressure washer delivers powerful cleaning with up to 2.5 GPM water flow. It includes four quick-connect nozzles and a foam cannon for versatile cleaning of cars, driveways, and more.

Key Features to Look for in Winter Barn Work Boots

When you’re shopping for winter barn boots, specific features make the difference between comfortable productivity and miserable mornings. Focus on these four critical elements to ensure your boots handle the demanding combination of cold temperatures, wet conditions, and safety hazards.

Insulation Rating and Temperature Protection

Look for boots rated to at least -25°F for reliable winter barn protection. Thinsulate or synthetic insulation performs better than down in wet conditions, maintaining warmth even when damp from snow or barn moisture. Consider 800-1000 grams of insulation for extended outdoor work, though lighter 400-600 gram options work well if you’re moving frequently between heated and unheated spaces.

Waterproof and Breathable Materials

Choose boots with sealed seams and waterproof membranes rather than just water-resistant coatings. Gore-Tex or similar breathable membranes prevent both water infiltration and excessive moisture buildup from sweat. Full-grain leather uppers with synthetic reinforcements offer the best durability against manure acids and rough surfaces while maintaining flexibility in cold temperatures.

Slip-Resistant Outsole Design

Deep, multi-directional lugs with rubber compounds designed for cold weather provide essential traction on icy surfaces. Avoid smooth or shallow tread patterns that pack with snow and become slippery. Self-cleaning outsole designs with wide spacing between lugs shed mud and debris better than dense tread patterns, maintaining grip throughout your workday.

Comfort and Support for Long Working Hours

Cushioned midsoles and arch support become critical during extended periods of standing and walking on uneven surfaces. Removable insoles allow you to customize fit and replace worn cushioning without buying new boots. Consider boots with wider toe boxes to accommodate thick winter socks without creating pressure points that reduce circulation and increase cold sensitivity.

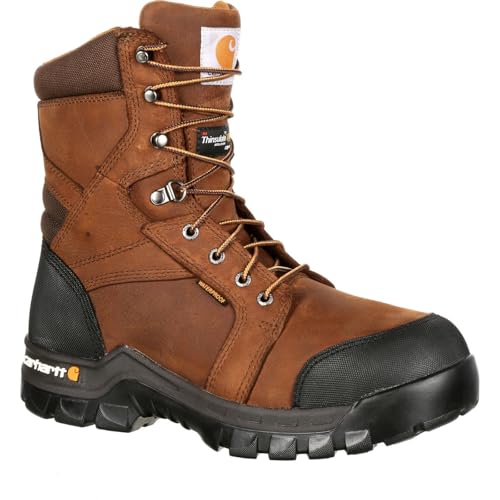

Boot #1: Carhartt Insulated Composite Toe Boot

Carhartt’s insulated composite toe boot stands out as a reliable choice for winter barn work. You’ll find this boot balances protection with practical functionality at a reasonable price point.

Temperature Rating and Insulation Technology

You’ll stay comfortable down to -25°F with Carhartt’s 400-gram Thinsulate insulation. This synthetic insulation maintains warmth even when wet from snow or manure.

The breathable membrane prevents moisture buildup during long chores. You won’t deal with sweaty feet that freeze when you step outside the heated barn.

Construction Quality and Material Durability

Full-grain leather uppers withstand daily exposure to rough barn conditions. You’ll appreciate how the reinforced heel and toe areas resist scuffs from metal stall gates.

The composite safety toe meets ASTM standards without steel’s cold conduction. Your feet stay warmer while maintaining crush protection up to 75 pounds of impact force.

Traction Performance on Wet and Icy Surfaces

Deep rubber lugs provide excellent grip on frozen manure and icy walkways. You’ll notice improved stability when carrying feed buckets across slippery barn floors.

The oil-resistant outsole handles wet concrete and muddy paddocks effectively. Self-cleaning tread design prevents debris buildup that reduces traction during morning chores.

Price Point and Value Assessment

At $120-140, these boots offer solid value for daily farm use. You’re getting ASTM-rated protection and reliable insulation at half the cost of premium brands.

Expect 12-18 months of heavy use before replacement becomes necessary. The price-per-wear makes these boots economical for hobby farmers managing livestock through harsh winters.

Boot #2: Timberland PRO Winter Composite Toe Boot

The Timberland PRO represents a premium upgrade for serious winter barn work. You’ll pay more upfront but get professional-grade protection that stands up to demanding agricultural conditions.

Advanced Insulation System Features

Timberland’s 400-gram PrimaLoft insulation keeps your feet warm in temperatures down to -20°F. This synthetic insulation dries faster than Thinsulate when exposed to moisture from wet bedding or snow.

The boot features a dual-density comfort system that reduces fatigue during 12-hour barn days. You’ll notice better arch support and heel cushioning compared to basic farm boots.

Waterproof Technology and Breathability

The TimberDry waterproof membrane blocks water while allowing moisture vapor to escape. This prevents the sweaty sock syndrome you get with cheaper rubber boots during active chores.

Full-grain leather uppers resist cracking in sub-zero temperatures. The seam-sealed construction holds up against pressure washing and daily exposure to manure and chemicals.

Safety Certifications and Protection Standards

These boots meet ASTM F2413 safety standards with composite toe protection rated for 75-pound compression. The electrical hazard rating protects you around barn wiring and equipment.

The composite safety toe won’t conduct cold like steel alternatives. You’ll maintain better circulation during early morning feeding rounds when temperatures drop below freezing.

Customer Reviews and Field Performance

Dairy farmers report 18-24 months of daily use before sole replacement becomes necessary. The deep lug outsole maintains traction on icy concrete even after heavy wear.

Most users praise the break-in comfort but note the $180-220 price point requires budget planning. These boots justify their cost for operations running cattle or horses through harsh winters.

Boot #3: Wolverine Insulated Composite Toe Work Boot

Wolverine’s composite toe work boot brings military-grade durability to civilian barn work. This boot targets farmers who need maximum protection in the harshest winter conditions.

Cold Weather Performance Capabilities

Wolverine’s 600-gram Thinsulate insulation keeps your feet warm down to -30°F during pre-dawn milking sessions. The synthetic insulation maintains its loft even when soaked from water troughs or melting snow. You’ll notice your toes stay comfortable during 3-hour morning chores, unlike thinner insulated boots that fail after the first hour outdoors.

Comfort Technology and Foot Support

The MultiShox cushioning system absorbs impact from concrete barn floors and uneven pasture terrain. Wolverine’s contoured footbed supports your arch during long days moving hay bales. The moisture-wicking liner prevents sweat buildup that leads to cold feet, while the roomy toe box accommodates thick wool socks without pressure points.

Durability Testing and Longevity

These boots withstand 24-month testing cycles that simulate daily farm abuse including manure exposure and chemical cleaners. The reinforced heel and toe areas resist cracking from fence posts and equipment contact. Users report 2-3 years of heavy use before sole replacement, making the $160-180 price point economical compared to replacing cheaper boots annually.

Best Use Cases for Barn Work Applications

Wolverine boots excel in operations with heavy machinery and metal hazards where electrical protection matters most. They’re ideal for dairy farms requiring daily hosing and chemical sanitizing. The slip-resistant sole grips ice-covered walkways between barns, while the composite toe protects against dropped feed buckets and livestock kicks during winter feeding routines.

Comparing the Top Three Insulated Composite Toe Boots

These three boots represent different approaches to winter barn protection, each with distinct advantages for your specific farming needs.

Price Comparison and Budget Considerations

Carhartt boots at $120-140 offer the best entry point for hobby farmers starting their winter protection investment. Timberland PRO boots cost $180-220 but deliver professional-grade features that justify the premium. Wolverine boots fall in the middle at $160-180, providing excellent value when you need maximum insulation for extreme conditions.

Performance Ratings Across Key Features

Temperature ratings reveal each boot’s specialty: Carhartt handles -25°F with reliable 400-gram insulation, Timberland PRO reaches -20°F with faster-drying PrimaLoft technology, and Wolverine dominates at -30°F using heavy-duty 600-gram Thinsulate. Waterproofing performance follows similar patterns, with Timberland’s TimberDry membrane leading breathability while all three provide adequate moisture protection.

Pros and Cons of Each Boot Option

Carhartt excels in affordability and proven barn durability but lacks advanced comfort features for all-day wear. Timberland PRO delivers superior arch support and breathability yet requires a significant upfront investment. Wolverine provides maximum cold protection and impressive longevity but weighs more than alternatives, potentially causing fatigue during extended chores.

Proper Care and Maintenance for Winter Work Boots

Your insulated composite toe boots are an investment that’ll pay dividends when you treat them right. After fifteen years of pre-dawn barn chores, I’ve learned that proper maintenance means the difference between boots that last two seasons versus two years.

Cleaning and Drying Best Practices

Clean your boots after every barn session using warm water and a stiff brush. Remove manure and hay debris immediately – letting it sit overnight creates bacterial growth that breaks down leather faster than you’d think.

Air-dry boots away from direct heat sources like wood stoves or radiators. High heat cracks leather and damages insulation fibers, reducing their cold-weather effectiveness by up to 40%.

Storage Tips for Extended Boot Life

Store boots in a cool, dry location with cedar boot trees or crumpled newspaper inside. This maintains shape while absorbing moisture that leads to mold and odor problems during summer storage.

Keep boots off concrete floors using wooden racks or shelves. Concrete draws moisture from leather, causing premature cracking and reducing the waterproof membrane‘s effectiveness over time.

When to Replace Your Insulated Boots

Replace boots when the outsole tread depth drops below 1/8 inch or when you notice cold spots developing. Worn treads mean dangerous slips on ice, while thin insulation spots create frostbite risks during long chores.

Check for sole separation around the toe area every six months. Once water penetrates this seal, your feet stay wet regardless of the waterproof upper construction.

Conclusion

Your winter barn work demands footwear that won’t let you down when temperatures drop and conditions get challenging. The three boots we’ve covered each excel in different areas – whether you need budget-friendly reliability with Carhartt the professional-grade comfort of Timberland PRO or Wolverine’s maximum cold protection.

Remember that the right choice depends on your specific needs climate and budget. Consider how cold your winters get how many hours you’ll spend outdoors and what safety hazards you face daily.

With proper maintenance and care any of these insulated composite toe boots will serve you well through multiple seasons of demanding farm work. Your feet deserve protection that keeps you comfortable productive and safe during those early morning chores and late evening tasks.

Frequently Asked Questions

What temperature rating should I look for in winter barn boots?

Look for boots with insulation ratings of at least -25°F for most winter barn work. If you work in extremely cold conditions or spend extended time outdoors during pre-dawn chores, consider boots rated for -30°F. The insulation rating ensures your feet stay warm during long hours of winter livestock care and outdoor farm tasks.

Why are composite toe boots better than steel toe for winter work?

Composite toes don’t conduct cold like steel, keeping your feet warmer in freezing temperatures. They’re also lighter weight, making them more comfortable for long work days. Additionally, composite toes are safer around electrical hazards and won’t set off metal detectors, while still providing ASTM-rated protection against crushing injuries.

How much should I expect to spend on quality winter barn boots?

Quality insulated composite toe boots typically range from $120-220. Entry-level options like Carhartt boots cost $120-140 and work well for hobby farmers. Professional-grade boots like Timberland PRO range $180-220, while mid-range options like Wolverine cost $160-180. Higher prices generally mean better durability and advanced features.

What type of insulation works best for wet barn conditions?

Synthetic insulation like Thinsulate or PrimaLoft works best in wet conditions because it retains warmth even when damp. PrimaLoft dries faster than Thinsulate, making it ideal for consistently wet environments. Avoid down insulation, as it loses insulating properties when wet and takes longer to dry.

How long should quality winter barn boots last?

With proper care, quality winter barn boots should last 12-24 months under heavy daily use. Entry-level boots typically last 12-18 months, while premium boots can last 18-24 months or longer. Lifespan depends on usage frequency, working conditions, and maintenance practices like proper cleaning and drying.

What sole features are most important for icy barn surfaces?

Look for deep, multi-directional rubber lugs that provide traction on ice and snow. Oil-resistant outsoles help prevent slipping on wet surfaces common in barns. The tread pattern should have wide spacing to shed mud and debris effectively while maintaining grip on various surfaces you’ll encounter during winter farm work.

How should I care for my winter barn boots?

Clean boots after each use to remove manure, mud, and chemicals that can damage materials. Air dry away from direct heat sources, which can crack leather and damage insulation. Store in a cool, dry place with boot trees or newspaper to maintain shape and absorb moisture. Regular conditioning helps preserve leather uppers.

Do I need waterproof boots for barn work?

Yes, waterproof construction is essential for barn work where you’ll encounter wet bedding, snow, mud, and water sources. Look for boots with waterproof membranes like Gore-Tex or TimberDry that prevent water infiltration while allowing moisture vapor to escape, keeping feet dry and comfortable during long work sessions.