6 Best Foundation Insulation Boards That Prevent Frost Heave

Discover the 6 best foundation insulation boards to prevent costly frost heave damage. Expert reviews of XPS, EPS, and polyiso options with R-values and installation tips.

Why it matters: Frost heave can cause thousands of dollars in foundation damage when freezing temperatures penetrate your home’s thermal envelope and create ice expansion beneath concrete slabs and footings.

The bottom line: Foundation insulation boards create a critical thermal barrier that prevents ground freezing around your foundation while reducing energy costs by up to 20% annually.

What’s ahead: We’ve researched and ranked the six most effective foundation insulation boards based on R-value performance compressive strength and moisture resistance to help you choose the right solution for your climate zone.

|

$41.99

|

$36.99

|

$26.99

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Frost Heave and Foundation Damage

Frost heave occurs when water in soil freezes and expands, creating powerful upward forces that can lift and crack your foundation.

What Is Frost Heave and How It Affects Foundations

Frost heave happens when soil moisture freezes and expands up to 9% in volume. This expansion creates tremendous upward pressure beneath your foundation, often exceeding 50,000 pounds per square foot. The freezing process draws additional water from surrounding soil through capillary action, amplifying the destructive force. Your foundation experiences uneven lifting that creates cracks, shifting, and structural instability over repeated freeze-thaw cycles.

Signs of Frost Heave Damage in Your Home

Horizontal cracks along your foundation walls indicate frost heave damage. You’ll notice doors and windows sticking or gaps appearing around frames as your foundation shifts. Interior signs include cracks in drywall, uneven floors, and gaps between baseboards and walls. Exterior symptoms show stepped cracks in brick or stone veneer, separation between foundation and siding, and visible foundation movement of 1-2 inches upward during winter months.

The Role of Insulation in Preventing Frost Heave

Foundation insulation boards create a thermal barrier that prevents ground freezing beneath your foundation. These boards maintain soil temperatures above 32°F by reducing heat loss from your heated basement or crawl space. Proper insulation extends the frost line away from your foundation by 2-4 feet, eliminating the freeze-thaw cycle that causes heave. Quality insulation boards also provide moisture resistance, preventing water infiltration that contributes to soil saturation and increased frost susceptibility.

Key Features to Look for in Foundation Insulation Boards

When selecting foundation insulation boards to prevent frost heave, you’ll need to evaluate three critical performance characteristics that determine long-term effectiveness.

R-Value Requirements for Different Climate Zones

Your climate zone determines the minimum R-value needed for effective frost protection. Zone 5 and colder regions require R-10 minimum, while zones 6-8 need R-15 to R-20 for adequate thermal resistance.

Higher R-values create thicker thermal barriers that push the frost line further from your foundation. This extra protection becomes crucial during extended cold snaps when temperatures drop below 10°F for multiple days.

Moisture Resistance and Vapor Barrier Properties

Foundation insulation boards must resist moisture absorption to maintain their insulating properties over decades. Look for boards with moisture absorption rates below 0.3% by volume after 24-hour water immersion testing.

Closed-cell foam boards offer superior moisture resistance compared to open-cell alternatives. Built-in vapor barriers eliminate the need for separate membrane installation, reducing both labor costs and potential failure points.

Compression Strength and Durability Standards

Your foundation insulation must withstand soil pressure and backfill loads without crushing or losing thickness. Quality boards should meet ASTM C578 standards with minimum 25 PSI compressive strength ratings.

Higher-density boards resist compression better but cost more upfront. Consider 40+ PSI ratings for deep foundations or areas with expansive clay soils that create additional pressure against foundation walls.

Extruded Polystyrene (XPS) Boards: The Gold Standard

XPS boards represent the premium choice for foundation insulation, offering exceptional thermal performance and moisture resistance. Their closed-cell structure and manufacturing process create a superior barrier against both heat loss and frost penetration.

Superior Moisture Resistance and Closed-Cell Structure

XPS boards feature a closed-cell foam structure that prevents water infiltration, maintaining R-values even in wet conditions. This design achieves moisture absorption rates below 0.1%, significantly outperforming other insulation materials. The integrated vapor barrier eliminates the need for additional moisture protection, simplifying installation while ensuring long-term thermal performance in below-grade applications.

High Compressive Strength for Below-Grade Applications

XPS boards deliver exceptional compressive strength ratings of 25-60 PSI, making them ideal for foundation installations. This strength prevents crushing under backfill pressure and maintains insulation integrity over decades. The rigid structure also provides structural support during installation, reducing the risk of damage from construction activities and soil movement.

Installation Best Practices and Common Challenges

XPS installation requires careful sealing of joints with compatible tape or foam to prevent thermal bridging. Common challenges include achieving proper adhesion to foundation walls and managing thermal expansion gaps. You’ll need to protect exposed edges from UV degradation and ensure proper drainage behind the boards to prevent moisture accumulation.

Expanded Polystyrene (EPS) Boards: Budget-Friendly Performance

EPS boards offer excellent value for foundation insulation while delivering reliable thermal protection against frost heave. You’ll find these white foam boards provide consistent R-values at a fraction of the cost of premium alternatives.

Cost-Effective Insulation with Reliable R-Values

EPS boards typically cost 30-50% less than XPS alternatives while maintaining R-values of 3.6-4.2 per inch. You’ll achieve R-15 thermal resistance with just 4 inches of thickness, making them ideal for budget-conscious projects. Their consistent performance delivers effective frost protection without premium pricing.

Lightweight Installation and Handling Benefits

EPS boards weigh approximately 1-2 pounds per cubic foot, making them easy to maneuver during installation. You’ll appreciate their lightweight nature when working in tight foundation spaces or overhead applications. Their easy cutting and shaping capabilities allow for quick modifications using standard utility knives.

Compatibility with Different Foundation Types

EPS boards adapt well to various foundation configurations including poured concrete, block walls, and slab-on-grade installations. You can install them vertically against foundation walls or horizontally beneath slabs without structural concerns. Their flexibility accommodates irregular surfaces and foundation transitions that rigid boards can’t handle effectively.

Polyisocyanurate (Polyiso) Boards: Maximum Thermal Performance

Polyisocyanurate boards deliver the highest thermal resistance per inch among rigid foam insulation options, making them ideal for foundations where space is limited. These boards excel in preventing frost heave while maintaining structural integrity under challenging conditions.

Highest R-Value Per Inch Among Rigid Foam Options

Polyiso boards achieve R-6.5 to R-7.2 per inch, outperforming XPS (R-5.0) and EPS (R-3.8) by significant margins. You’ll need only 2.5 inches of polyiso to reach R-15 thermal resistance, compared to 3 inches of XPS or 4 inches of EPS. This superior performance reduces installation depth and construction costs while maximizing thermal protection against frost heave.

Fire-Resistant Properties and Building Code Compliance

Polyiso boards meet stringent fire safety requirements with flame spread ratings below 25 and smoke development under 450 per ASTM E84 standards. You’ll find these boards comply with most building codes without additional fire-resistant coverings in many applications. This compliance simplifies permitting processes and reduces installation complexity compared to other rigid foam options that require protective barriers.

Temperature Performance Considerations

Polyiso maintains peak R-values at temperatures above 40°F but experiences thermal drift in colder conditions, dropping to R-5.5 at 20°F. You’ll need to account for this reduction when calculating insulation requirements for severe climate zones. Consider upgrading to thicker polyiso boards in regions with extended sub-freezing periods to maintain adequate frost heave protection throughout winter months.

Mineral Wool Boards: Fire-Safe and Breathable Option

Mineral wool boards offer unique advantages for foundation insulation applications where fire safety and moisture management are primary concerns. These boards provide excellent thermal performance while maintaining breathability that prevents moisture buildup.

Non-Combustible Properties for Enhanced Safety

Mineral wool boards won’t ignite or contribute to fire spread, making them ideal for foundation installations near boilers or electrical equipment. These boards maintain their structural integrity at temperatures exceeding 1,800°F and comply with Class A fire ratings. You’ll find mineral wool boards particularly valuable in basement installations where fire safety codes require non-combustible materials within specific distances of heat sources.

Vapor Permeable Design for Moisture Management

Mineral wool’s open-fiber structure allows water vapor to pass through while blocking liquid water infiltration. This breathability prevents condensation buildup that can lead to mold growth and structural damage in foundation walls. You can install mineral wool boards without vapor barriers in most climates, as their permeability naturally regulates moisture levels and prevents trapped humidity that damages other insulation types.

Installation Requirements and Special Considerations

Mineral wool boards require mechanical fastening rather than adhesive attachment due to their fibrous composition. You’ll need to use specialized fasteners designed for masonry applications and ensure proper protective equipment during installation. Consider that mineral wool boards cost 15-25% more than foam alternatives and require careful handling to prevent fiber compression that reduces thermal performance.

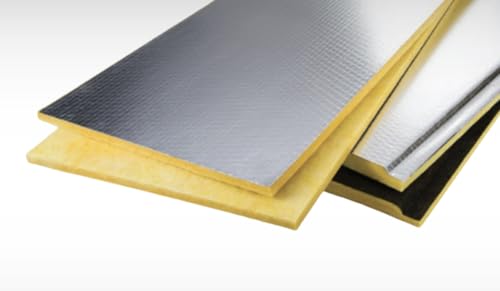

Hybrid Composite Boards: Advanced Multi-Layer Solutions

These innovative boards combine different insulation materials into single panels, delivering enhanced frost heave protection through engineered layer systems.

Combining Multiple Materials for Optimal Performance

Hybrid composite boards integrate foam cores with reflective barriers and rigid facing materials to maximize thermal resistance. You’ll find XPS cores paired with aluminum facers that boost R-values by 15-20% compared to standard boards. These multi-layer systems create superior thermal barriers while maintaining structural integrity under foundation loads.

Integrated Vapor Barriers and Drainage Features

Advanced composite boards feature built-in vapor barriers and drainage channels that eliminate moisture accumulation around foundations. You’ll benefit from pre-installed drainage grooves that direct water away from the structure while maintaining continuous thermal protection. These integrated systems reduce installation time and prevent the thermal bridging that occurs with separate vapor barrier installations.

Long-Term Performance and Warranty Coverage

Hybrid composite boards typically offer 25-year warranties with guaranteed R-value retention of 95% or higher throughout their service life. You’ll find these boards maintain consistent thermal performance even after freeze-thaw cycles, with compressive strength ratings that exceed 40 PSI. Manufacturers back these products with comprehensive coverage that includes both material defects and thermal performance degradation.

Installation Tips and Best Practices for Foundation Insulation

Proper installation techniques determine whether your foundation insulation boards will effectively prevent frost heave for decades. Following these best practices ensures maximum thermal performance and long-term durability.

Proper Preparation and Surface Requirements

Clean foundation surfaces thoroughly before installing insulation boards to ensure optimal adhesion. Remove dirt, debris, and loose concrete particles using a wire brush or pressure washer. Allow surfaces to dry completely for 24-48 hours before application. Apply primer to porous concrete surfaces to improve adhesive bonding strength and prevent moisture wicking between the foundation and insulation boards.

Sealing Joints and Preventing Thermal Bridging

Seal all joints between insulation boards using compatible foam sealant or tape to eliminate thermal bridging pathways. Apply continuous beads of adhesive along board edges before installation. Use spray foam to fill gaps larger than 1/4 inch between boards. Install boards in staggered patterns to minimize continuous joint lines that could create thermal weak points throughout your foundation system.

Professional vs. DIY Installation Considerations

DIY installation works well for shallow foundations with straight walls and minimal obstacles like utility penetrations. Professional installation becomes necessary for complex foundation geometries, deep excavations exceeding 4 feet, or installations requiring special equipment like mechanical fasteners. Consider hiring professionals when working near electrical systems or when local building codes require certified installation for warranty coverage and permit approval.

Conclusion

Protecting your foundation from frost heave doesn’t have to be complicated when you choose the right insulation boards. Each material offers distinct advantages – from XPS’s superior moisture resistance to EPS’s budget-friendly performance and Polyiso’s space-saving thermal efficiency.

Your climate zone will ultimately determine which R-value you need but remember that proper installation is just as crucial as material selection. Taking time to seal joints and follow manufacturer guidelines will ensure your foundation stays protected for decades.

Don’t wait until you see cracks in your walls or notice sticking doors. Investing in quality foundation insulation boards now will save you thousands in potential repair costs while keeping your home comfortable year-round.

Frequently Asked Questions

What is frost heave and how does it damage foundations?

Frost heave occurs when soil moisture freezes and expands beneath concrete foundations, creating powerful upward forces that can exceed 50,000 pounds per square foot. This expansion lifts and cracks foundations, causing horizontal cracks in walls, sticking doors and windows, and interior drywall damage. The freeze-thaw cycle repeatedly stresses foundation materials, leading to significant structural problems over time.

How do foundation insulation boards prevent frost heave?

Foundation insulation boards create a thermal barrier that prevents ground freezing around your foundation. They maintain soil temperatures above 32°F and extend the frost line away from the structure. By blocking heat transfer, these boards prevent the freeze-thaw cycle that causes soil expansion and foundation damage, while also reducing energy costs by up to 20% annually.

What R-value do I need for my climate zone?

R-value requirements depend on your climate zone. Colder regions (Zone 5 and below) need minimum R-10 insulation, while Zones 6-8 require R-15 to R-20 for effective thermal resistance. Higher R-values create thicker thermal barriers that push the frost line further from your foundation, which is crucial during extended cold periods.

What’s the difference between XPS and EPS insulation boards?

XPS (Extruded Polystyrene) boards offer premium performance with exceptional moisture resistance (below 0.1% absorption) and integrated vapor barriers. They maintain R-values even when wet and provide 25-60 PSI compressive strength. EPS (Expanded Polystyrene) boards are budget-friendly, costing 30-50% less than XPS, with R-values of 3.6-4.2 per inch and reliable thermal protection for most applications.

How important is moisture resistance in foundation insulation?

Moisture resistance is critical for foundation insulation effectiveness. Boards should have moisture absorption rates below 0.3% to maintain thermal performance. Closed-cell foam boards with built-in vapor barriers are recommended because they prevent water infiltration that can reduce R-values and cause insulation failure. Wet insulation loses thermal resistance and can lead to mold growth.

What compression strength should foundation insulation boards have?

Quality foundation insulation boards should meet ASTM C578 standards with minimum compressive strength of 25 PSI. Higher ratings (up to 60 PSI) are recommended for deep foundations or areas with expansive clay soils. Adequate compression strength prevents the boards from crushing under soil pressure and maintains thermal performance over time.

Are there budget-friendly options for foundation insulation?

Yes, EPS boards offer excellent budget-friendly protection, typically costing 30-50% less than premium XPS boards. With 4 inches of thickness, EPS can achieve R-15 thermal resistance suitable for most climates. These lightweight boards (1-2 pounds per cubic foot) are easy to install and compatible with various foundation types while providing reliable frost heave protection.

What are the benefits of professional installation?

Professional installation ensures proper sealing of joints to prevent thermal bridging, correct adhesion techniques, and proper handling of thermal expansion gaps. Professionals have experience with complex foundation geometries and can identify potential issues before they become problems. While DIY installation is possible, professional work typically comes with warranties and guaranteed performance.