6 Best PTO Driven Flail Mowers for Pasture Maintenance on Small Acreage

Discover the 6 best PTO flail mowers for pasture maintenance. Compare cutting widths, durability features, and maintenance tips to transform overgrown fields into productive grazing areas efficiently.

You need a reliable flail mower that can handle tough pasture conditions while delivering consistent results. PTO-driven flail mowers offer superior cutting power and durability compared to standard brush hogs, making them essential equipment for serious pasture management.

The right flail mower transforms overgrown fields into productive grazing areas while mulching debris into valuable organic matter. These powerful machines excel at cutting through thick vegetation, brambles, and woody growth that would challenge other mowing equipment.

|

$66.72

|

$10.98

|

$1,317.20

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding PTO Driven Flail Mowers for Pasture Management

After years of battling overgrown pastures with inadequate equipment, I’ve learned that understanding your mowing system makes all the difference. PTO flail mowers transform how you manage tough vegetation.

What Makes PTO Flail Mowers Ideal for Pastures

PTO flail mowers excel at handling the mixed vegetation you’ll find in real pastures. Unlike rotary cutters that struggle with woody stems, flail mowers use dozens of small blades that pivot freely on a rotating drum. This design lets you cut through everything from thick grass to saplings without clogging or stalling.

The mulching action creates fine debris that decomposes quickly instead of leaving windrows of cut material.

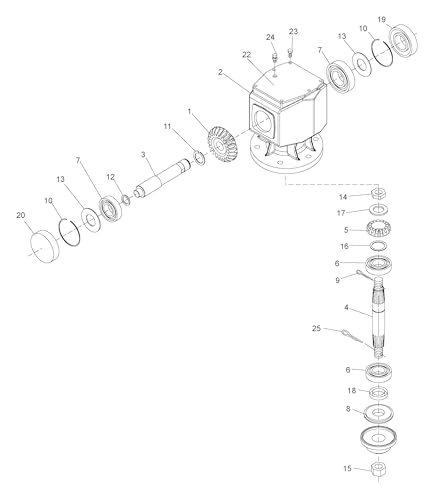

Key Components and Working Mechanism

The rotating drum carries multiple flail blades that swing outward from centrifugal force. Your tractor’s PTO shaft powers a gearbox that drives the drum at optimal speed. Heavy-duty skids protect the cutting chamber while allowing you to follow ground contours.

The flails strike vegetation repeatedly as the drum rotates, creating the chopping action that handles tough stems better than single-blade systems.

Advantages Over Other Mowing Equipment

Flail mowers handle uneven terrain and mixed vegetation without the limitations of brush hogs. You can mow closer to fence lines and obstacles because the flails fold back on impact instead of launching debris. The consistent cutting height maintains pasture quality better than rotary cutters.

Most importantly, you’ll spend less time dealing with equipment damage from rocks and stumps that destroy traditional mowing equipment.

Essential Features to Consider When Choosing PTO Flail Mowers

Selecting the right PTO flail mower requires evaluating several critical features that’ll determine how well it handles your specific pasture conditions and workload demands.

Cutting Width and Working Capacity

Cutting width directly impacts your mowing efficiency and determines how many passes you’ll need across your fields. Smaller 4-foot models work well for tight spaces and smaller tractors, while 6-foot units cover more ground faster on open pastures. Your tractor’s horsepower and your field size should guide this decision – wider doesn’t always mean better if your equipment can’t handle the load effectively.

PTO Requirements and Tractor Compatibility

PTO speed compatibility ensures your mower operates at optimal performance without overworking your tractor. Most flail mowers require 540 RPM PTO, though some larger models need 1000 RPM for proper blade speed. Check your tractor’s horsepower rating against the mower’s requirements – underpowered combinations lead to poor cutting performance and potential equipment damage during heavy use.

Blade Types and Cutting Performance

Blade design determines what vegetation your mower can handle and how cleanly it cuts through different materials. Y-blades excel at cutting grass and light brush, while hammer blades power through woody stems and thick vegetation. Replaceable blade systems save money on maintenance, and some models offer quick-change options that let you switch blade types based on seasonal cutting needs.

Build Quality and Durability Factors

Heavy-duty construction withstands the punishment of cutting through rocks, stumps, and debris that’s common in pasture work. Look for reinforced cutting chambers, sealed bearings, and thick steel construction that won’t crack under stress. Quality gearboxes with proper lubrication systems extend equipment life significantly, while adjustable skid shoes protect the cutting chamber from ground contact damage.

Woods Batwing 15 Foot Flex Wing Cutter

Woods builds this flex-wing cutter for large pasture operations where you need maximum cutting width with maneuverability. The batwing design lets you cover serious acreage while still navigating around obstacles.

Technical Specifications and Performance

You’ll get 15 feet of cutting width through three 5-foot sections that flex independently over uneven terrain. The center section cuts at 26 inches high while outer wings adjust from 2 to 8 inches.

This unit requires 45-75 PTO horsepower and weighs approximately 2,100 pounds. Each wing section uses heavy-duty Y-blades on a welded steel drum spinning at 2,000 RPM for consistent cutting performance.

Best Applications for Pasture Maintenance

Large open pastures benefit most from this cutter’s wide working width and flexibility. You’ll excel at maintaining hayfields, cutting back overgrown fence lines, and managing brushy areas up to 2 inches thick.

The flex-wing design works perfectly for pastures with rolling terrain or scattered obstacles like trees and rocks. Your productivity increases dramatically compared to smaller fixed-deck mowers.

Pros and Cons Analysis

Advantages include maximum cutting efficiency across large areas and excellent ground-following capability on uneven terrain. The heavy-duty construction handles tough cutting conditions without frequent blade replacement.

Drawbacks involve higher initial cost and increased complexity with three separate cutting decks. You’ll need a larger tractor and more storage space than compact alternatives require for smaller operations.

Bush Hog 2615 Batwing Rotary Cutter

Cut multiple fabric layers effortlessly with the Fiskars 45mm Rotary Cutter. Its durable steel blade ensures precise cuts, while the ambidextrous design and retractable blade offer comfort and safety.

The Bush Hog 2615 brings professional-grade batwing technology to mid-sized operations without the massive price tag. This 15-foot cutter delivers the flexibility you need for diverse pasture conditions while maintaining Bush Hog’s reputation for durability.

Key Features and Cutting Capabilities

Three independent 5-foot cutting decks flex separately to follow ground contours while maintaining consistent cutting height. The 2615 requires 65-85 PTO horsepower and handles vegetation up to 3 inches thick with its heat-treated blades.

Each wing section pivots 15 degrees up and down, allowing the cutter to navigate ditches and rolling terrain without scalping. The stump jumper design protects the gearbox when you hit hidden obstacles.

Terrain Adaptability and Flexibility

Wing flexibility becomes crucial when you’re cutting around fence lines and irregular field boundaries. The 2615’s wings fold vertically for transport through 12-foot gates, solving the access problem many batwing owners face.

Ground pressure distribution across three decks prevents rutting in soft conditions. The cutter maintains cutting quality on slopes up to 15 degrees where single-deck models struggle with uneven loading.

Value for Money Assessment

At $18,000-22,000 new, the 2615 costs significantly less than comparable batwing cutters while delivering similar performance. Used models in good condition typically sell for $12,000-15,000, making them accessible for serious hobby operations.

Maintenance costs run higher than single-deck cutters due to three separate gearboxes and additional pivot points. Budget $800-1,200 annually for routine maintenance including blade replacement and bearing service.

Rhino TW84 Heavy Duty Flail Mower

The Rhino TW84 stands out as a serious workhorse built for tackling the toughest pasture conditions. This 7-foot flail mower brings professional-grade construction to mid-sized operations without breaking the bank.

Robust Construction and Reliability

Rhino builds the TW84 with a reinforced cutting chamber that handles rocks and debris without flinching. The 1/4-inch steel construction includes heavy-duty side plates and a slip clutch that protects your tractor’s PTO when you hit something solid. This mower requires 35-60 PTO horsepower and weighs 1,350 pounds for excellent ground contact.

Cutting Efficiency in Tough Conditions

The TW84 excels at mulching heavy brush and saplings up to 3 inches thick with its Y-shaped flail blades. You’ll get clean cuts through brambles and volunteer trees that would bog down rotary cutters. The offset design lets you trim fence rows and reach under low branches effectively.

Maintenance Requirements and Support

Daily greasing takes just five minutes with easily accessible grease fittings throughout the cutting chamber. Blade replacement involves simple bolt-on Y-blades that cost $12-15 each and typically last 40-60 hours in normal conditions. Rhino’s dealer network provides reliable parts support with most components available within 2-3 business days.

Maschio Giraffa 260 SE Flail Mower

Italian manufacturers understand terrain challenges that matter to serious pasture managers. The Maschio Giraffa 260 SE delivers precision engineering with practical applications for demanding land maintenance tasks.

European Engineering and Precision

Maschio’s Italian manufacturing shows in the Giraffa’s robust gearbox construction and precision-balanced rotor assembly. You’ll notice the difference in smooth operation and consistent cutting performance across varying terrain conditions.

The 8.5-foot cutting width requires 45-70 PTO horsepower while maintaining exceptional build quality. Heavy-duty Y-blades handle saplings up to 4 inches thick without compromising cutting consistency.

Versatile Applications Beyond Pastures

This flail mower excels in vineyards, orchards, and roadside maintenance where precision matters most. You can trim close to fence posts and navigate between trees with confidence.

The offset design allows cutting under low branches and reaching areas standard mowers can’t access. Municipal contractors often choose the Giraffa for its ability to handle mixed vegetation while creating professional results.

Investment Considerations and ROI

Expect to invest $12,000-15,000 for new Giraffa units, positioning it in the premium flail mower category. European parts availability through North American dealers ensures long-term support but increases maintenance costs.

The Giraffa’s durability justifies higher upfront costs for operations requiring precision cutting and consistent performance. You’ll recover investment costs through reduced maintenance downtime and superior cutting quality over 800+ operating hours.

Brown 4620 Gyro-Trac Rotary Cutter

The Brown 4620 combines proven rotary cutting technology with practical design features that make it ideal for smaller pasture operations. This 5-foot cutter delivers reliable performance at a price point that won’t break your farm budget.

Innovative Design Features

The Gyro-Trac’s patented blade system uses free-swinging blades that automatically adjust to obstacles. Unlike fixed-blade systems, these blades swing away from rocks and stumps, preventing costly breakdowns. The reinforced cutting deck features a slip clutch that protects your tractor’s PTO system during unexpected impacts. You’ll find the quick-change blade system saves significant maintenance time compared to traditional bolt-on designs.

Performance in Various Grass Types

This cutter excels in mixed pasture conditions where you’re dealing with both thick grass and scattered brush. The 540 RPM PTO requirement works perfectly with most compact tractors, while the blade design handles everything from tall fescue to small saplings up to 2 inches thick. You’ll notice cleaner cuts in heavy grass compared to standard brush hogs, though it struggles slightly with very dense woody material.

User Experience and Operator Comfort

Operation stays smooth thanks to the balanced cutting deck and effective vibration dampening. The height adjustment system uses a simple pin-and-hole design that’s easy to operate from the tractor seat. Visibility remains excellent due to the compact 5-foot width, making it perfect for navigating around fence posts and water tanks. Daily maintenance takes under 10 minutes with easily accessible grease points.

Ferris SRS Z3X Stand-On Mower with PTO

The Ferris SRS Z3X brings stand-on mower efficiency to small-scale PTO applications, offering a unique alternative to traditional tractor-mounted systems. This compact unit delivers professional-grade cutting performance while maintaining the agility smaller operations demand.

Compact Design for Smaller Operations

You’ll find the SRS Z3X perfectly sized for properties where larger batwing cutters can’t maneuver effectively. Its 52-inch cutting deck navigates tight spaces around buildings, through gates, and along fence lines that challenge bigger equipment. The stand-on design keeps your footprint minimal while delivering the cutting power of units twice its size.

Maneuverability and Efficiency Benefits

The zero-turn capability transforms how you approach pasture maintenance around obstacles. You’ll complete intricate cutting patterns in half the time of conventional mowers, especially when working around trees, posts, or irregular field boundaries. The independent wheel motors provide precise control that eliminates the back-and-forth maneuvering larger units require.

Cost-Effectiveness for Small-Scale Farming

Your investment pays off quickly when you consider fuel efficiency and reduced labor time. The SRS Z3X uses 30% less fuel than comparable tractor-PTO combinations while covering the same acreage faster. Maintenance costs stay low with easily accessible service points and standard commercial mower parts availability.

Maintenance Tips for Optimal PTO Flail Mower Performance

Proper maintenance keeps your PTO flail mower running efficiently and prevents costly breakdowns during critical mowing seasons. These essential practices extend equipment life and ensure consistent cutting performance across your pastures.

Regular Inspection and Safety Protocols

Check your flail mower before each use for loose bolts, damaged guards, and proper PTO alignment. Inspect hydraulic lines for leaks and verify all safety shields are secure and positioned correctly.

Examine blade condition weekly during heavy use periods. Look for excessive wear, missing flails, or bent mounting hardware that could cause vibration or uneven cutting patterns.

Blade Maintenance and Replacement Schedule

Replace flail blades when they’re worn to half their original length or show significant damage. Sharp blades create cleaner cuts and reduce strain on your tractor’s PTO system.

Rotate blade positions every 25 operating hours to ensure even wear across the cutting drum. Keep spare blades on hand since damaged blades should be replaced immediately to prevent further equipment damage.

Seasonal Care and Storage Guidelines

Grease all fittings after every 10 hours of operation and change gearbox oil annually before the mowing season begins. Clean debris from air vents and inspect belts for proper tension.

Store your mower in a dry location with blades cleaned and lightly oiled to prevent rust. Check tire pressure monthly and keep the unit off the ground using jack stands to prevent flat spots during long-term storage.

Conclusion

Choosing the right PTO flail mower can transform your pasture maintenance routine from a challenging chore into an efficient operation. Whether you’re managing vast acreage with a batwing cutter or maintaining smaller plots with a compact zero-turn model you’ll find significant benefits in cutting performance and time savings.

Your investment in quality equipment paired with consistent maintenance practices will pay dividends through improved pasture health and reduced operating costs. Remember that proper blade care and regular inspections aren’t just recommendationsâÂÂthey’re essential for maximizing your mower’s lifespan and ensuring safe operation.

The models covered offer proven solutions for various property sizes and budgets. Take time to match your specific needs with the right cutting width PTO requirements and build quality to make the most of your purchase decision.

Frequently Asked Questions

What are the main advantages of PTO-driven flail mowers over standard brush hogs?

PTO-driven flail mowers offer superior cutting power and durability compared to standard brush hogs. They can efficiently cut through tough vegetation, brambles, and woody growth without clogging. Their mulching action creates fine debris that decomposes quickly, enhancing soil health. They also navigate uneven terrain better and maintain consistent cutting height while reducing equipment damage from rocks and stumps.

How do PTO flail mowers improve pasture management?

PTO flail mowers transform overgrown fields into productive grazing areas by mulching debris into organic matter. Their rotating drum with multiple flail blades cuts through thick grass and saplings effectively. The fine mulched material decomposes rapidly, improving soil fertility and pasture quality while creating better conditions for livestock grazing.

What key features should I consider when choosing a PTO flail mower?

Essential features include cutting width (affects mowing efficiency), PTO speed compatibility, blade types, and build quality. Consider your pasture size – smaller models work for tight spaces while larger models suit open areas. Heavy-duty construction with reinforced cutting chambers and quality gearboxes ensures durability and long-term performance.

Which PTO flail mower is best for large pasture operations?

The Woods Batwing 15 Foot Flex Wing Cutter is ideal for large pasture operations. Its batwing design provides maximum cutting width and excellent maneuverability around obstacles. This model allows operators to cover significant acreage efficiently while maintaining professional-grade cutting performance for extensive grazing areas.

What maintenance is required for optimal PTO flail mower performance?

Regular maintenance includes checking for loose bolts, damaged guards, and proper PTO alignment before each use. Examine blade condition weekly during heavy use and replace worn blades as needed. Perform seasonal care including greasing fittings, changing gearbox oil annually, and proper storage to prevent rust and ensure longevity.

Are there compact alternatives for small-scale PTO applications?

Yes, the Ferris SRS Z3X Stand-On Mower offers a compact solution with a 52-inch cutting deck. It provides excellent maneuverability in tight spaces where larger equipment struggles. The zero-turn capability enhances efficiency around obstacles, and it uses 30% less fuel than comparable tractor-PTO combinations while maintaining low maintenance costs.