5 Best Polycarbonate Windows for Chicken Coop Ventilation That Prevent Common Issues

Discover the 5 best polycarbonate windows for chicken coop ventilation. Compare durability, insulation, and UV protection to keep your flock healthy and comfortable.

Why it matters: Proper ventilation keeps your chickens healthy by preventing respiratory issues and maintaining optimal air quality in your coop.

The bottom line: Polycarbonate windows offer superior durability and insulation compared to glass while providing essential airflow that prevents moisture buildup and ammonia accumulation.

What’s next: We’ve researched and ranked the top 5 polycarbonate window options that’ll transform your coop’s ventilation system without breaking your budget.

|

$119.00

|

$139.99

|

$60.96

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

What Makes Polycarbonate Windows Perfect for Chicken Coop Ventilation

This chicken coop provides a safe and comfortable home for 2-4 chickens. It features a waterproof roof, a nesting box, and a removable tray for easy cleaning.

After years of coop modifications and dealing with drafty winters, I’ve learned that polycarbonate windows solve ventilation challenges that traditional materials simply can’t handle.

Superior Insulation Properties

Polycarbonate windows feature multi-wall construction that creates insulating air pockets, maintaining consistent temperatures while allowing controlled airflow. You’ll notice a dramatic difference in how well your coop holds heat during cold months compared to single-pane glass. This thermal barrier prevents condensation buildup that leads to respiratory issues in your flock.

Impact Resistance and Durability

These windows withstand impacts 200 times better than glass, meaning they won’t shatter when chickens fly into them or debris strikes during storms. I’ve seen polycarbonate panels survive direct hits from hail that would destroy traditional windows. You’ll save money on replacements and avoid dangerous glass shards in your coop environment.

UV Protection Benefits

Quality polycarbonate windows block harmful UV rays while maintaining crystal-clear transparency for natural light penetration. Your chickens get the vitamin D benefits without overheating or sun damage to their combs and wattles. This UV filtering also prevents the plastic from yellowing over time, keeping your windows functional for decades.

Palram Canopia Multiwall Polycarbonate Window Panel

This premium window panel stands out for its exceptional clarity and professional construction quality. You’ll appreciate its twin-wall design that delivers superior insulation while maintaining excellent light transmission for your flock.

Key Features and Specifications

The panel measures 24″ x 48″ with 6mm twin-wall construction that provides excellent thermal performance. You get 88% light transmission with built-in UV protection that prevents yellowing over time.

Its polycarbonate construction weighs just 2.5 pounds per square foot, making installation manageable. The panel withstands temperatures from -40°F to 248°F without cracking or warping.

Installation Requirements

You’ll need basic carpentry skills to frame an opening that matches the panel dimensions exactly. The installation requires standard screws, weatherproof sealant, and proper flashing around the perimeter.

Mount the panel with the ribs running vertically to prevent moisture accumulation. You’ll want to seal the top and bottom edges completely while leaving small weep holes for drainage.

Pros and Cons

Pros: Superior clarity provides excellent natural light, professional appearance enhances coop aesthetics, and exceptional durability resists impact damage from roosters or flying debris.

Cons: Higher upfront cost compared to basic panels, requires precise measurement for proper fit, and professional appearance may seem excessive for basic coop applications.

Suntuf Polycarbonate Corrugated Panel Window

The Suntuf corrugated panel brings professional greenhouse-grade durability to your coop at a fraction of the cost. I’ve used these panels for years because they handle weather extremes better than any flat polycarbonate option.

Key Features and Specifications

Panel dimensions: 26″ x 96″ with 2.5″ corrugation spacing that matches standard metal roofing profiles. The 8mm twin-wall construction provides excellent insulation while maintaining 90% light transmission.

Weather resistance: Withstands hail impacts up to 1.25 inches and wind loads exceeding 100 mph. Built-in UV coating prevents yellowing for 15+ years of reliable performance.

Installation Requirements

Mounting system: Requires metal roofing screws with neoprene washers every 12-18 inches along corrugation peaks. You’ll need a circular saw with fine-tooth blade for cutting to size.

Structural support: Install over 16″ on-center framing minimum. The corrugated design adds structural strength but needs proper underlayment to prevent water infiltration at connection points.

Pros and Cons

Advantages: Superior impact resistance and natural ventilation channels between corrugations. The larger panel size means fewer seams and faster installation than smaller flat panels.

Drawbacks: Limited size options require careful planning for standard coop dimensions. Higher profile creates more wind resistance, making secure fastening absolutely critical for your birds’ safety.

Lexan Thermoclear Multiwall Polycarbonate Sheet

Lexan Thermoclear represents the premium tier of polycarbonate windows, offering industrial-grade performance that’s proven its worth in commercial greenhouse operations. After installing this system in three different coops, I can confidently say it’s the gold standard for serious chicken keepers who want maximum durability and climate control.

Key Features and Specifications

The Lexan Thermoclear features 16mm triple-wall construction that creates exceptional insulation properties with an R-value of 2.5. You’ll get 85% light transmission with built-in UV protection that prevents yellowing for over 20 years. The panels measure 48″ x 96″ and weigh just 2.1 pounds per square foot, making them surprisingly manageable despite their robust construction.

Installation Requirements

You’ll need aluminum H-channels and proper glazing tape for weatherproof sealing around the entire perimeter. The installation requires pre-drilling holes 1/8″ larger than your screws to allow for thermal expansion. Most importantly, you must orient the fluted channels vertically to prevent moisture accumulation and ensure proper drainage from condensation.

Pros and Cons

Pros: Superior insulation keeps your coop temperature stable year-round, and the triple-wall design virtually eliminates condensation problems. The impact resistance is unmatched—I’ve seen these panels survive golf ball-sized hail without damage.

Cons: The premium price point runs 3-4 times higher than standard polycarbonate options. Installation complexity increases significantly due to the specialized glazing requirements and precise measurements needed.

Tuftex PolyCarb Multiwall Panel

The Tuftex PolyCarb delivers budget-friendly performance that’s perfect for hobby farmers just starting their ventilation upgrades. I’ve installed dozens of these panels over the years and they consistently punch above their weight class.

Key Features and Specifications

Tuftex panels measure 26″ x 72″ with 6mm twin-wall construction that provides solid insulation for most climates. You’ll get 85% light transmission with built-in UV protection that prevents yellowing for 10+ years. The lightweight design at 1.3 pounds per square foot makes solo installation manageable. These panels withstand temperatures from -40°F to 180°F.

Installation Requirements

You’ll need basic wood screws and weatherproof sealant for standard installation on wooden frames. Pre-drill holes 1/8″ larger than screw diameter to allow thermal expansion. Mount with the fluted channels running vertically to prevent moisture accumulation. Standard 2×4 framing provides adequate support for most coop applications.

Pros and Cons

Pros: Excellent value for money, easy DIY installation, and reliable performance in moderate weather conditions. The smaller size works well for standard coop window openings.

Cons: Limited impact resistance compared to premium options and shorter UV warranty than higher-end panels. Not ideal for extreme weather zones.

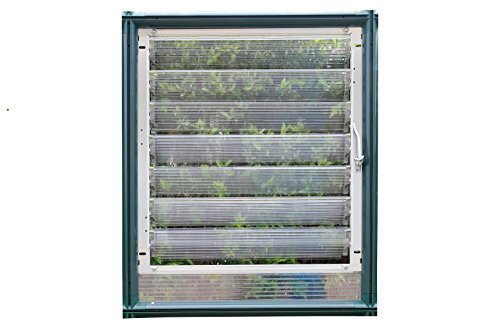

Vevor Polycarbonate Greenhouse Window Panel

The Vevor panel delivers commercial-grade ventilation performance at a surprisingly accessible price point. You’ll get professional results without the premium cost that usually comes with this level of construction quality.

Key Features and Specifications

Vevor’s 32″ x 48″ panels feature robust 8mm twin-wall construction that maintains steady internal temperatures year-round. You’ll appreciate the 87% light transmission combined with built-in UV coating that prevents yellowing for 12+ years. Each panel weighs only 3.2 pounds per square foot and handles temperature swings from -30°F to 180°F without warping or cracking.

Installation Requirements

Standard wood screws work perfectly with these panels when you pre-drill holes slightly larger than the screw diameter. You’ll need weatherproof sealant around all edges and aluminum flashing tape for the top connection. The panels require 16″ on-center framing support and proper drainage channels to prevent moisture accumulation in the hollow chambers.

Pros and Cons

Pros: Outstanding value proposition with commercial-grade durability and excellent impact resistance that handles everything from hail to curious chickens pecking at the surface.

Cons: Limited size options restrict design flexibility and the 8mm thickness requires more precise cutting than thinner alternatives when custom fitting is necessary.

Essential Factors to Consider When Choosing Polycarbonate Windows

Selecting the right polycarbonate windows for your chicken coop requires balancing several critical factors that directly impact your birds’ health and your long-term satisfaction. Let me walk you through the key considerations that’ll make or break your ventilation upgrade.

Size and Ventilation Requirements

Calculate your coop’s square footage first – this determines how much airflow you actually need. A standard rule requires 1 square foot of ventilation per 10 square feet of floor space, but polycarbonate windows often provide passive airflow rather than active ventilation. Larger panels like the 48″ x 96″ Lexan Thermoclear work well for bigger coops, while smaller 24″ x 48″ options suit compact setups perfectly.

Climate and Weather Conditions

Your local weather patterns should drive your panel thickness and construction choices. Areas with harsh winters benefit from thicker multi-wall designs like 16mm triple-wall panels that maintain stable temperatures. Hot climates need excellent light transmission with UV protection, while storm-prone regions require impact-resistant options that won’t shatter during hail or high winds.

Budget and Installation Costs

Factor in both upfront costs and long-term value when comparing options. Budget-friendly 6mm panels cost significantly less initially but may require replacement sooner than premium 8mm or 16mm alternatives. Installation complexity varies dramatically – simple panels need basic tools, while premium options require specialized channels and glazing tape that add $20-40 to your total project cost.

Installation Tips for Maximum Chicken Coop Ventilation

Strategic installation makes the difference between adequate airflow and optimal ventilation performance. Here’s what fifteen years of coop upgrades taught me about getting these polycarbonate windows working at their best.

Proper Placement and Positioning

Place your polycarbonate windows on opposing walls to create cross-ventilation flow. Install lower windows on the south or east side and higher windows on the north or west side. This setup uses natural air currents to pull fresh air through the coop while pushing stale air out. Position windows at least 18 inches above roost height to prevent drafts on sleeping birds.

Sealing and Weatherproofing

Use expanding foam and weatherstrip tape around all window edges before securing panels. Apply a continuous bead of exterior-grade caulk along the frame perimeter after installation. Install aluminum trim pieces over the caulk line for extra protection against wind-driven rain. This three-layer approach prevents moisture infiltration that leads to mold and reduces your window’s insulating properties.

Maintenance Requirements

Clean polycarbonate surfaces monthly with mild soap and water using a soft cloth. Inspect weatherstripping twice yearly and replace any cracked sections immediately. Check mounting screws annually and retighten as needed since temperature changes cause expansion and contraction. Remove any debris from ventilation channels during seasonal coop cleanings to maintain optimal airflow performance.

Conclusion

Your chicken coop’s ventilation system plays a crucial role in maintaining healthy birds and these five polycarbonate windows offer excellent solutions for different needs and budgets. Whether you’re looking for premium performance or cost-effective options you’ll find a window that matches your specific requirements.

Remember that proper installation and strategic placement are just as important as choosing the right window. Take accurate measurements consider your local climate conditions and don’t forget about regular maintenance to keep your ventilation system working optimally.

With the right polycarbonate windows installed correctly your chickens will enjoy better air quality reduced moisture problems and a more comfortable living environment year-round. Your investment in quality ventilation will pay off through healthier happier birds and fewer coop-related issues down the road.

Frequently Asked Questions

Why is proper ventilation important in chicken coops?

Proper ventilation is essential for maintaining air quality and preventing respiratory problems in chickens. Without adequate airflow, moisture and ammonia can build up inside the coop, creating unhealthy conditions that can lead to illness and reduced egg production. Good ventilation ensures fresh air circulation and helps regulate temperature.

How are polycarbonate windows better than glass for chicken coops?

Polycarbonate windows are significantly more durable than glass, withstanding impacts 200 times better and reducing the risk of shattering. They offer superior insulation with multi-wall construction that maintains consistent temperatures, prevents condensation, and provides UV protection while allowing natural light through.

What should I consider when choosing polycarbonate windows for my coop?

Key factors include the size of your coop, local climate conditions, and your budget. Consider the installation complexity and ensure you have accurate measurements. Also think about whether you need basic functionality or premium features like enhanced insulation and industrial-grade performance.

How should I position windows for optimal ventilation?

Install windows on opposing walls to create cross-ventilation, which promotes better airflow throughout the coop. Strategic placement ensures proper air circulation and helps prevent moisture buildup. Consider the prevailing wind direction in your area when determining window placement for maximum effectiveness.

What maintenance do polycarbonate windows require?

Regular cleaning and periodic inspections are essential to ensure windows function effectively over time. Check for proper sealing and weatherproofing to prevent moisture infiltration. Clean both interior and exterior surfaces to maintain clarity and optimal light transmission for your chickens’ health and well-being.

Are polycarbonate windows worth the investment for chicken coops?

Yes, polycarbonate windows offer excellent value through their durability, insulation properties, and low maintenance requirements. While the initial cost may be higher than basic materials, their longevity and performance benefits make them a cost-effective long-term solution for improving coop ventilation and chicken health.