6 Best Aftermarket Tractor Gauges For Enhanced Performance Old Farmers Swear By

Upgrade your tractor with 6 gauges veteran farmers trust. These aftermarket tools offer precise monitoring for enhanced performance and engine longevity.

You’re halfway through tilling the garden when the tractor sputters, the engine note changes, and you’re left wondering if it’s a fuel issue or something far more serious. That vague temperature needle that’s been hovering in the "normal" zone for a decade suddenly feels useless. For a hobby farmer, a dead tractor isn’t just an inconvenience; it’s a weekend lost and a potential repair bill that can sink a season’s budget.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Upgrade Your Tractor’s Stock Gauges?

Most older tractors came with the bare minimum. You often get a temperature gauge with a vague "C" and "H," an oil pressure light that only comes on when the damage is already done, and a fuel gauge that’s more of a suggestion than a measurement. These are not tools for proactive maintenance; they are alarms for catastrophic failure.

Upgrading your gauges is about shifting from a reactive to a proactive mindset. Instead of waiting for a warning light, you get real-time data that tells a story about your engine’s health. You can see the oil pressure drop slightly over time, indicating a potential issue. You can watch the temperature creep up on a hot day and back off the throttle before you overheat.

This isn’t about adding flashy chrome to a workhorse. It’s about investing in reliability. A few hundred dollars in quality gauges can save you thousands in engine repairs and, more importantly, save you from the frustration of being stranded in the middle of a critical task. Think of it as cheap insurance for your most valuable piece of equipment.

Isspro R603 EGT Pyrometer for Engine Health

If you run a diesel, an Exhaust Gas Temperature (EGT) gauge, or pyrometer, is one of the best additions you can make. It measures the temperature of the exhaust gas as it leaves the engine. This single number tells you exactly how hard your engine is working and how efficiently it’s burning fuel.

Pushing a tractor too hard, like pulling a heavy disc through compacted soil, can send EGTs soaring. Sustained high temperatures can lead to cracked pistons, a damaged turbo, and a host of other expensive problems. A pyrometer gives you an immediate warning, allowing you to ease up or shift down a gear to let things cool off.

It also helps you find the sweet spot for fuel efficiency. By keeping the EGTs in the optimal range, you ensure a complete fuel burn, getting the most power out of every drop of diesel. It’s a tool that protects your engine while also saving you money at the pump.

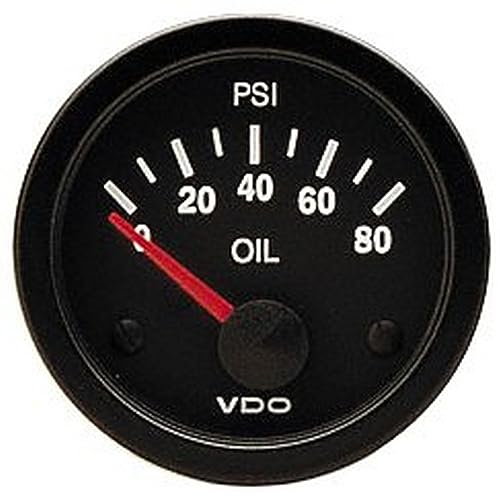

VDO Vision Series Oil Pressure Gauge for Safety

The factory oil pressure "idiot light" is the worst kind of liar. It stays off, telling you everything is fine, right up until the moment it isn’t. When that light flickers on, it means pressure has dropped to a dangerously low level, and internal engine damage has likely already begun.

A VDO oil pressure gauge replaces that binary on/off warning with a continuous, numerical reading. You’ll learn what your tractor’s normal operating pressure is when cold and when fully warmed up. This baseline is your most powerful diagnostic tool. A reading that’s consistently low could signal a worn oil pump or bearings. A reading that drops as the engine gets hot could mean your oil is thinning out too much.

This gauge is your engine’s pulse. It provides the earliest possible warning of internal trouble, giving you time to shut down and investigate before a minor leak or a failing part turns into a seized engine. There is no single better investment for engine longevity.

AutoMeter Z-Series Water Temperature Gauge

Overheating can kill a tractor engine faster than almost anything else. A clogged radiator, a failing water pump, or a stuck thermostat can quickly lead to a warped cylinder head or a blown head gasket. The stock temperature gauge, with its wide, undefined "normal" range, doesn’t give you the precision needed to catch a problem early.

The AutoMeter Z-Series provides a clear, numerical reading of your coolant temperature. You can see the engine warm up to its precise operating temperature, and you’ll know immediately if it starts to climb even a few degrees higher than usual. This is invaluable when you’re doing low-speed, high-load work like brush hogging on a 90-degree day.

Knowing your exact temperature also helps with engine wear. Consistently running an engine that isn’t fully warmed up can cause premature wear on internal components. A quality temperature gauge ensures you’re working the machine only when it’s ready, extending its life and improving its performance.

Faria Euro Black Tachometer with Hour Meter

Many older, smaller tractors don’t even have a tachometer. You’re left to guess the engine RPM by ear, which is a terrible way to operate PTO-driven implements. A mower, tiller, or post-hole digger is designed to run at a specific PTO speed (usually 540 RPM), which corresponds to a specific engine speed.

Installing a tachometer takes the guesswork out of the equation. You can set the throttle perfectly for the task at hand, ensuring your implements work efficiently and without putting undue stress on them or the tractor’s driveline. Running a brush hog too slow results in a poor cut; running it too fast is dangerous and hard on the gearbox.

The integrated hour meter is arguably just as valuable. Keeping track of maintenance intervals with a logbook is easy to forget. An hour meter gives you an accurate, undeniable record of use, so you know exactly when it’s time to change the oil, check the filters, and perform other vital maintenance. It’s the key to turning a reactive repair schedule into a proactive maintenance plan.

Hewitt Industries Universal Fuel Level Gauge

It sounds simple, but a broken fuel gauge is one of the most common and frustrating problems on an old tractor. Running out of fuel isn’t just an inconvenience that requires a long walk back to the barn. If you’re running a diesel, it often means you have to bleed the air out of the fuel lines—a messy, time-consuming task.

A universal fuel level gauge from a reputable brand like Hewitt is a straightforward fix. These kits typically come with a new sending unit that can be adapted to fit most fuel tanks and a clear, reliable dash gauge. You’ll finally be able to trust what you see.

This is a quality-of-life upgrade that pays for itself in saved time and frustration. Knowing you have a quarter tank left means you can finish the row before heading back to refuel, instead of guessing based on how long you’ve been running. It brings a little bit of modern reliability to an older machine.

GlowShift Black 7 Color Voltmeter Gauge

A tractor’s electrical system is often neglected until the day it refuses to start. A voltmeter is a simple gauge that gives you a constant window into the health of your battery and charging system. It tells you far more than a simple "battery" warning light ever could.

With the engine off, the voltmeter should read around 12.6 volts for a healthy, fully charged battery. If it’s much lower, you know the battery is weak or something is draining it. With the engine running, the reading should jump to between 13.5 and 14.5 volts, indicating that the alternator or generator is properly charging the battery.

If you see the voltage slowly dropping while you’re working, you have an early warning that your charging system is failing. This gives you the chance to finish your work and get the tractor back to the shed before the battery dies completely, leaving you stranded. It’s a simple tool that prevents a very common headache.

Installing and Calibrating Your New Gauges

Don’t be intimidated by the installation process. For most of these gauges, if you can change your own oil, you can handle this. The key is to take your time, read the instructions, and make sure you have the right parts before you start.

Most gauges require three connections: power, ground, and a signal from a sending unit.

- Power: Find a wire that is "hot" only when the key is on. This prevents the gauges from draining your battery.

- Ground: Ensure you have a clean, metal-to-metal connection to the tractor’s frame for a solid ground. Poor grounds are the source of most electrical gremlins.

- Sender: This is the most important part. You’ll replace the old "idiot light" switch or temperature sender with the new one that came with your gauge. Use thread sealant to prevent leaks.

For a fuel gauge, calibration is key. You’ll need to measure the resistance of the sending unit when the tank is empty and when it’s full, and then adjust the gauge accordingly. It takes a little patience, but the result is a gauge you can finally trust. If you’re truly uncomfortable with wiring, any auto or tractor mechanic can do this work for you, but it’s a very rewarding DIY project.

Upgrading your tractor’s gauges isn’t about restoration or aesthetics; it’s a practical investment in knowledge and reliability. Each gauge gives you a vital piece of information, turning you from a simple operator into an informed manager of your machine’s health. By seeing problems develop in real-time, you can trade expensive, emergency repairs for simple, proactive maintenance, keeping your trusted iron in the field where it belongs.