7 Best Thin Pipe Insulation For Indoor Farm Water Lines To Avoid Costly Leaks

For indoor farms, the right thin pipe insulation is crucial to prevent costly leaks. We review 7 top options to safeguard your water lines and crops.

You’ve seen it before—a small, innocent-looking puddle on the floor of your indoor farm. You wipe it up, but it’s back the next day, right under that cold water line feeding your hydroponics system. That isn’t a leak; it’s condensation, and it’s a silent threat that can lead to slips, mold, and damaged equipment. Choosing the right thin pipe insulation is a small, proactive step that prevents these costly headaches down the road.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Insulate Your Indoor Farm Water Lines?

The core problem is simple physics. Your indoor farm is warm and humid, but the water running through your supply lines is often quite cold. When that warm, moist air hits the cold surface of the pipe, the water vapor condenses into liquid, drips, and creates a perpetual puddle.

This isn’t just an annoyance. That constant moisture can promote mold and mildew growth on floors and walls, creating an unhealthy environment for both you and your plants. It’s also a serious slip hazard on a concrete or epoxy floor. Over time, consistent dripping can even damage electrical equipment or the subfloor beneath your growing area.

Insulating your pipes creates a thermal barrier. It keeps the warm, humid air from ever touching the cold pipe surface, stopping condensation before it can start. While it might slightly help maintain water temperature, its primary job in an indoor farm is moisture control, and that’s a job you can’t afford to ignore.

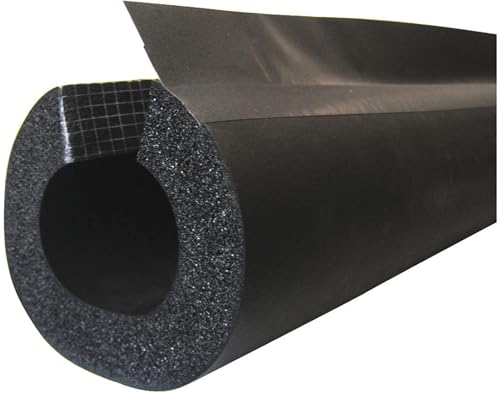

Armacell Armaflex for Superior Condensation Control

When you absolutely cannot afford to have condensation, Armaflex is the answer. This is a professional-grade, closed-cell elastomeric rubber insulation. Its dense, flexible material is inherently a vapor barrier, meaning moisture can’t work its way through the insulation to the pipe.

Think of it as the most robust solution. While basic foam insulations work, they can be more permeable to water vapor over time, especially in very high-humidity environments. Armaflex is built to perform in commercial HVAC systems, so it easily handles the conditions of an indoor farm. It’s also naturally resistant to microbial growth, which is a huge plus.

The tradeoff is often installation and cost. Non-slit versions require you to slide them over the pipe before final assembly, which is great for new builds but difficult for retrofits. However, Armacell also makes self-sealing versions that offer the same material benefits with a much easier installation process. For critical lines running over sensitive equipment, the extra security is well worth it.

Frost King Self-Sealing Foam for Easy Installs

For most general-purpose applications, Frost King’s self-sealing foam tubes are the definition of quick and effective. You’ll find this stuff in any hardware store. It’s made of polyethylene, comes pre-slit down the side, and has two strips of factory-applied adhesive. You just open it up, wrap it around the pipe, and press the seam shut.

This is your go-to for speed. If you have dozens or hundreds of feet of exposed pipe to cover, the peel-and-stick application saves an enormous amount of time. It provides a good thermal barrier and does a solid job of preventing condensation in moderately humid conditions.

The weak point, however, is the seam itself. If the adhesive isn’t perfectly aligned or if the pipe has a slight bend, you can get small gaps. These gaps are all it takes for moisture to form. For this reason, it’s a fantastic solution for most areas, but you might want something more robust for pipes in your most humid zones or those running directly above electrical panels.

M-D Tuff-Tube: Durable Polyethylene Insulation

M-D’s Tuff-Tube is a step up in ruggedness from standard polyethylene foam. While the material is similar, it’s designed with a tougher, more puncture-resistant outer skin. This makes it ideal for pipes in high-traffic areas where they might get bumped by equipment, carts, or your own boots.

Think about those water lines running along the base of a wall or under a workbench. Standard foam insulation can get torn or crushed easily, compromising its effectiveness. Tuff-Tube is built to withstand that kind of incidental contact, ensuring the insulation stays intact and continues to do its job for years.

Installation is straightforward, similar to other polyethylene tubes, though not all versions are self-sealing. You might need to secure it with tape or zip ties. The key decision here is location. If the pipe is out of the way and unlikely to be disturbed, standard foam is fine. If it’s in a vulnerable spot, the extra durability of Tuff-Tube is a smart investment.

K-Flex Insul-Tube: Flexible for Tight Bends

K-Flex Insul-Tube is another elastomeric rubber option, prized for its incredible flexibility. If you’re dealing with plumbing that has a lot of tight bends or weaves around equipment, this is your problem-solver. It can be bent and contorted into tight radii without kinking or compressing, which is a common failure point for more rigid foam insulation.

When a stiffer insulation is forced around a 90-degree elbow, the outer edge stretches thin and the inner edge bunches up. This creates inconsistencies in the thermal barrier and can even cause the seam to pop open. K-Flex’s rubber construction maintains its thickness and integrity around those curves, providing a continuous, uninterrupted layer of protection.

This makes it the perfect choice for complex manifold systems or any plumbing that isn’t a simple straight run. Like Armaflex, it’s a built-in vapor barrier and offers excellent long-term performance against moisture and microbial growth. It’s a premium product for situations where precision and complete coverage are essential.

Everbilt Rubber Pipe Wrap for Awkward Fittings

No matter how well you insulate the straight runs of pipe, you’ll be left with exposed valves, spigots, and T-fittings. These uninsulated metal components get just as cold as the pipe and will sweat profusely, undermining all your hard work. This is where a specialty product like Everbilt’s rubber pipe wrap tape comes in.

This isn’t for insulating long pipes; it’s a flexible, self-adhering rubber tape designed specifically for irregular shapes. You simply stretch and wrap it tightly around the fitting, overlapping it to create a seamless, waterproof seal. It conforms perfectly to any shape, ensuring every square inch of the cold surface is covered.

Think of it as the detail work that completes the job. A single dripping valve can create a surprisingly large puddle. Leaving your fittings exposed is one of the most common mistakes people make. Having a roll of this tape on hand is non-negotiable for a truly effective insulation project.

Thermacel Polyethylene for Economical Protection

Sometimes, you just have a massive amount of pipe to cover and a tight budget. Thermacel is a brand that offers basic, no-frills closed-cell polyethylene insulation. It provides a solid thermal barrier and gets the fundamental job done without the premium features of other options.

This is the economical choice. It typically doesn’t come with self-sealing adhesive strips, so you’ll need to secure it yourself. You can use zip ties every foot or so, but the best method is to run a full-length seal with a quality foil tape.

This option is perfectly adequate for large projects in environments with moderate humidity where you need good performance for the lowest cost. It’s a workhorse product that proves you don’t always need to spend top dollar to solve a problem. Just be prepared to put in a little extra labor during installation to ensure the seams are properly sealed.

Duck Brand Foil Tape for Securing Insulation Seams

This isn’t insulation, but it’s arguably one of the most critical components of a successful insulation job. Duck Brand Foil Tape (or a similar high-quality foil tape) is essential for sealing the seams on any non-rubber, pre-slit pipe insulation. The adhesive on self-sealing tubes is good, but it’s not a permanent, airtight vapor barrier.

The purpose of the foil tape is to create a complete, uninterrupted seal along the longitudinal seam and at the joints where two pieces of insulation meet. This prevents warm, moist air from getting through the crack and reaching the pipe, which would cause condensation under the insulation. This "seam sweating" is a common point of failure.

Don’t use standard duct tape. It will fail in humid conditions. You must use a proper foil tape. Running a strip of this tape along every seam turns a decent insulation job into a professional one. It’s a simple, inexpensive step that guarantees the long-term performance of your entire system.

Ultimately, the best pipe insulation is the one that fits your specific needs and is installed correctly. A high-end rubber insulation is useless if its seams are left open, and an economical foam can perform beautifully if it’s meticulously sealed with foil tape. Take the time to assess your farm’s humidity, budget, and plumbing complexity, because a little bit of effort now will save you from cleaning up puddles for years to come.