6 Heavy-Duty Anchors For Livestock Shelters Old Farmers Swear By

Keep your livestock shelters grounded in any storm. This guide covers the 6 heavy-duty, time-tested anchors that experienced farmers swear by.

You can build the sturdiest livestock shelter in the county, but it’s just a heavy, expensive kite without the right anchors. A sudden squall or a relentless winter gale doesn’t care how well you joined the timbers; it only cares how well the structure is joined to the earth. Getting this part right is the difference between a safe haven for your animals and a pile of twisted metal in your neighbor’s pasture.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Proper Anchoring Prevents Shelter Disaster

The biggest mistake people make is underestimating wind. We tend to think of wind as a horizontal force that pushes against a wall, but its most destructive power comes from uplift. When wind hits a structure, it creates pressure on the windward side and a vacuum on the leeward side, effectively trying to lift the entire roof and building right off the ground.

A simple run-in shed with an open front is a perfect wind trap. Air gets forced inside and pushes up on the roof, while wind passing over the top creates lift—just like an airplane wing. Without heavy-duty anchors pulling it down, the shelter has no chance. This isn’t just about losing your investment; it’s about preventing a catastrophic failure that could injure or kill the animals you’re trying to protect.

Proper anchoring transfers these lifting and shearing forces from the shelter’s frame deep into the ground. It turns the earth itself into a partner, using its immense weight and frictional resistance to hold your structure fast. A well-anchored shelter becomes part of the landscape, not just something sitting on top of it.

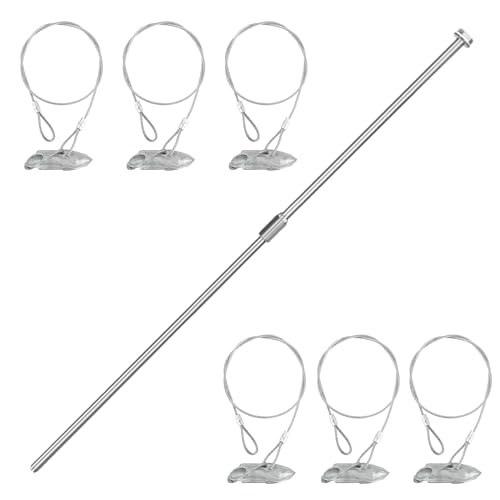

Duckbill Earth Anchors for Versatile Grip

Duckbill anchors are a brilliant piece of engineering, especially for soil that isn’t full of rock. Imagine a heavy-duty steel toggle bolt you drive into the ground. You use a long steel rod to hammer the anchor down, and when you pull back on the attached cable, the anchor head pivots sideways, locking itself horizontally deep in the soil.

These are fantastic for securing hoop houses or fabric-covered run-ins where you can’t or don’t want to pour concrete. They provide incredible resistance to uplift, often rated for thousands of pounds of holding power, depending on the model and soil type. The key is getting them deep enough into undisturbed, compacted soil. Driving them into loose topsoil won’t do much good.

The main tradeoff is their dependence on soil conditions. In very sandy or loose gravel, they may not "bite" effectively. Conversely, in dense clay or rocky ground, driving them in can be an exhausting, back-breaking chore. But for the vast majority of pasture soils, they offer a semi-permanent solution with more holding power than any stake or screw-in anchor.

SONOTUBE Forms for Poured Concrete Footings

When you’re building a permanent pole barn or a heavy-duty run-in, nothing beats a poured concrete footing. SONOTUBE forms are essentially heavy-duty cardboard tubes that you place in a hole to shape the concrete pier. This method creates a solid, heavy foundation that provides immense resistance to both uplift and lateral forces.

The process is straightforward but labor-intensive. You auger or dig a hole below the frost line, place the tube, fill it with concrete, and set your post anchor hardware into the wet mix. By going below the frost line, you prevent the ground’s freezing and thawing cycles from "heaving" your posts out of the ground over time. This is the gold standard for permanence.

This approach is obviously not for portable shelters. Once the concrete is cured, that footing isn’t going anywhere without an excavator. It also requires buying or renting a mixer, hauling bags of concrete, and a good bit of sweat equity. But for a structure you expect to last for decades, the stability and peace of mind are worth every bit of the effort.

ShelterLogic Easy Hook Anchors for Portability

Many hobby farmers rely on portable shelters for rotational grazing or temporary housing. For these, you need an anchor that is both effective and removable. The corkscrew-style auger anchors, like the popular ShelterLogic Easy Hooks, are a common and effective solution for this specific need.

These anchors consist of a steel shaft with a wide auger flight at the bottom. You literally screw them into the ground using a long rod or a heavy-duty drill for leverage. They provide a surprising amount of holding power in decent soil by using the soil’s own structure to resist being pulled out. They are ideal for securing calf hutches, temporary chicken tractors, or lightweight run-ins that you plan to move with the seasons.

However, their limitations are important to understand. Their holding power is a fraction of what a Duckbill or concrete pier can offer. In very soft, wet, or sandy soil, they can pull out under extreme wind loads. Think of them as excellent temporary fasteners, not permanent foundations.

GoliathTech Helical Piles in Problem Soils

Sometimes you face truly difficult ground conditions—mucky clay, high water tables, or soil that just won’t compact. In these situations, a standard concrete footing might sink, shift, or fail. This is where helical piles, sometimes called screw piles, come into play.

Think of a helical pile as a giant, galvanized steel screw. They are installed using hydraulic machinery that drives them deep into the earth until they reach a stable soil layer or bedrock. The machine measures the torque required to turn the pile, giving a precise, engineered value for its load-bearing capacity. This isn’t a DIY job; it’s a professional installation that provides an absolutely rock-solid foundation on the worst possible ground.

The obvious tradeoff is cost. Helical piles are significantly more expensive than any other option on this list. But if you’re building a large, valuable structure on questionable soil, the cost of a proper foundation is far less than the cost of a building that fails. It’s an investment in certainty.

Simpson Strong-Tie Post Bases for Secure Footing

An anchor’s job isn’t finished once it’s in the ground; it has to connect securely to the structure. This is where hardware like Simpson Strong-Tie post bases becomes non-negotiable. These heavy-gauge steel brackets create a secure connection between a wooden post and a concrete pier.

More importantly, they elevate the base of the wood post an inch or so off the concrete. This small gap is critical. It prevents moisture from wicking up from the concrete into the end grain of the post, which is the number one cause of premature rot and structural failure in pole buildings. Sinking an untreated post directly into concrete is a recipe for disaster in just a few years.

Using a proper post base is a small extra step and a minor cost, but it can easily double the functional lifespan of your shelter’s frame. It’s one of those details that separates a well-built structure from an amateur one. Always factor these connectors into your plan when pouring concrete footings.

DIY Rebar J-Hooks for Cost-Effective Hold

For smaller, lightweight structures on a tight budget, the old-timer’s rebar J-hook is a viable option. The concept is simple: take a 3- or 4-foot length of heavy rebar (#4 or #5), heat one end with a torch, and bend it into a "J" shape. You then drive these deep into the ground at an angle to pin down the base frame of a hoop house or a small animal shelter.

The key to making these work is length and angle. A short, vertically driven stake pulls out easily. A long hook driven at a 45-degree angle, with the hook catching the shelter’s base frame, forces the wind to pull against a much larger column of soil. It’s a classic example of using leverage and physics to make a simple material effective.

This is a "better than nothing" solution. It offers far more holding power than simple tent stakes but cannot compete with engineered anchors in a serious storm. Use them for low-risk applications, like securing a chicken tractor in a sheltered yard, not for a large run-in on an exposed hilltop.

Matching Your Anchor System to Local Conditions

There is no single "best" anchor. The right choice is a careful calculation based on your specific situation. Before you buy a single piece of hardware, walk your property and think through these four critical factors:

- Soil Type: Is your ground soft loam, dense clay, sand, or solid rock just inches below the surface? A Duckbill that’s perfect for loam is useless in rock, where you’d need to drill and set anchor bolts in concrete.

- Wind Exposure: Is the shelter tucked behind a thick treeline or is it sitting on a wide-open, windswept hill? The more exposed the location, the more you need to over-engineer your anchoring system.

- Shelter Permanence: Are you building a generational barn or a temporary lambing shed you’ll move in six weeks? Your timeline dictates your method, from portable screw-in anchors to permanent concrete piers.

- Budget and Labor: How much can you afford to spend, and how much work are you willing and able to do yourself? Pouring concrete is cheap in materials but rich in labor; helical piles are the opposite.

Take the time to assess these variables honestly. Choosing the right anchor isn’t just a construction detail; it’s a risk management decision. Get it right, and you’ll sleep soundly through the worst storms.

Don’t treat your shelter’s foundation as an afterthought. The ground beneath your feet is your strongest ally against the weather, so choose an anchor that connects your structure to it with unshakable confidence. A little extra planning and investment here pays dividends for the entire life of your shelter.