7 Electric Sheep Shearer Setup Guides for First-Year Success

Master your electric shearer setup for a successful first year. Our 7 guides cover blade tension, oiling, and safety for a smooth, efficient shear.

That brand-new electric shearer sitting in its case feels like pure potential, a promise of a quicker, cleaner shearing day. But the difference between a smooth first run and a frustrating, wool-jammed mess often comes down to the first 15 minutes of setup. Getting the tension, oil, and assembly right from the start isn’t just a recommendation; it’s the foundation for your success.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Pre-Shearing Prep: Your Essential Setup Checklist

Before you even plug in your shears, your workspace dictates your workflow. You need a clean, dry, and well-lit area with a flat surface for your tools. Trying to adjust tension on a wobbly bucket or in the dim light of a dusty barn is a recipe for error. Lay out a piece of old carpet or a tarp to work on; it keeps your tools clean and provides a soft landing if you drop something.

Your pre-flight checklist is non-negotiable. It ensures you have everything within arm’s reach before the sheep is in front of you. You don’t want to be hunting for shear oil with a half-shorn, stressed-out ewe waiting.

- Shearing Oil: Not 3-in-1 oil, not motor oil. Use proper shearing oil.

- Screwdriver/Wrench: The one that came with your shears.

- Cleaning Brush: For clearing wool from the vent and blades.

- Extra Set of Blades: Have a sharp, clean set of cutters and combs ready to go.

- A Rag: For wiping down the handpiece and blades.

Remember, shearing is a hot, dirty job for the machine. Proper lubrication is the single most important factor in preventing your shears from overheating. A new machine needs oil on the cutter, the comb, the tension pin, and in any designated oil holes on the head. Oil frequently—every five to ten minutes—during the job.

Oster ShearMaster: Calibrating for First Use

The Oster ShearMaster is a workhorse, but its power can be its downfall if not managed correctly. Out of the box, the tension is often set for shipping, not for shearing. Your first job is to get this right, and it starts with understanding the tension knob on top of the head. It’s not just a dial; it controls the precise pressure between the moving cutter and the stationary comb.

To set it for the first time, make sure the machine is unplugged. Tighten the tension knob clockwise until you feel it stop completely. Don’t force it past this point. This is your zero point. Now, turn the knob counter-clockwise about one and a half full turns. This is a reliable starting position for most wool types.

Plug in the shears and turn them on, holding them away from you. Listen. You should hear a smooth, high-pitched whir. If you hear a loud, grinding clatter, the tension is too loose. If the motor sounds like it’s straining or bogging down, it’s too tight. The goal is the minimum amount of tension required to cut wool cleanly. Start with the 1.5-turn baseline, make a test pass on a clean patch of wool, and tighten by a quarter-turn at a time until it cuts like a hot knife through butter.

Lister Star: A Lightweight Setup for Small Flocks

The Lister Star is a favorite for small flocks precisely because it’s less intimidating. It’s lighter and has less vibration, but the setup principles are identical. Its tensioning system is straightforward, but its lighter build means you can feel the effects of poor setup more quickly. Over-tighten a Lister, and you’ll feel the heat build up in the head almost immediately.

Your initial setup follows the same rule: tighten the tension knob until it seats, then back it off one and a half turns. Because the Star is a cooler-running machine by design, it’s tempting to neglect oiling. Don’t. The smaller motor works hard, and proper lubrication is critical to its longevity. Oil the blades before you start and every few minutes during use.

The key with the Lister is to let the machine do the work. If it’s not cutting, your first instinct should be to check the tension or change to sharp blades, not to push harder. A properly set up Star glides through the fleece with minimal effort, making it a fantastic tool for your first few seasons of shearing.

Andis Heavy Duty: Tensioning for Smooth Shearing

Andis shears feel solid in your hands, and their tensioning system is robust. The common mistake here is assuming more power means you need more tension. The opposite is true. A powerful motor like the one in the Andis Heavy Duty can easily overcome excessive tension, but it will generate tremendous heat, dull your blades prematurely, and leave ugly ridges in the fleece.

Like the others, find your zero point by tightening the knob until it stops, then back it off. For the Andis, a single full turn is often a better starting point than one and a half. The tolerances on these machines are tight. Once you turn it on, listen for that smooth hum. You’re tuning the machine by ear as much as by feel.

A great test is to hold the shears up and see if the cutter blade "chatters" back and forth slightly. A tiny bit of chatter means the tension is light, which is good. As you tighten the knob, that chatter will disappear. The sweet spot is just past the point where the chatter stops. This ensures you have enough pressure to cut but not so much that you’re creating excessive friction.

Heiniger Xtra: Assembling Your Professional Kit

Opening a Heiniger case feels different. These are professional-grade tools, and the setup reflects that precision. The first step is inspecting the components. Ensure the drive connection from the motor to the handpiece is clean and engages smoothly. This isn’t a single-unit body like some other shears; it’s a system.

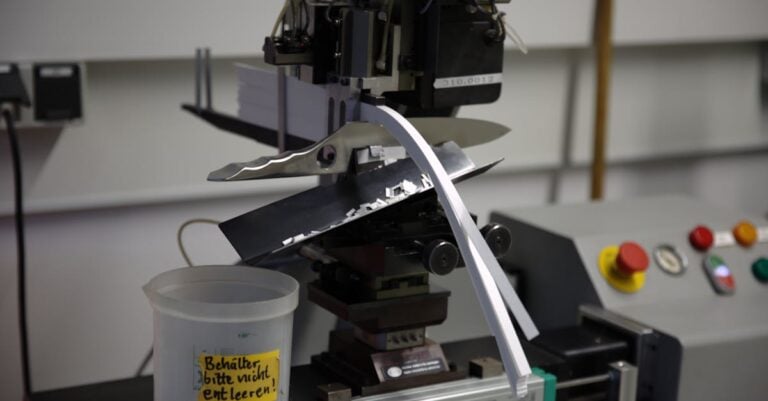

Assembling the head requires care. When you fit the comb and cutter, make sure the fork (the part that drives the cutter) is correctly seated in the cutter’s guide holes. Before applying tension, check that the cutter blade can move freely side-to-side by hand. If it binds, something is misaligned. Don’t proceed until it moves smoothly.

Tensioning a Heiniger is an exercise in finesse. Use the standard method of tightening fully and backing off 1.5 turns as your baseline. However, Heiniger machines are so well-balanced that you can often run them with slightly less tension than other brands. The goal is a perfect cut with minimal heat. Think of it as calibrating a precision instrument, not just cranking down a knob. Take your time, make small adjustments, and let the quality of the machine do its job.

BEIYUAN Shears: Unboxing and Initial Adjustments

The budget-friendly BEIYUAN shears have made electric shearing accessible to many, but they require a more thorough initial setup. These machines are often coated in a thick, protective grease for shipping. Your first task is to take a rag and some degreaser and clean the entire head assembly meticulously. Pay special attention to the tension pin and blade surfaces.

Next, check every single screw on the machine. It’s not uncommon for screws on the body or head to be loose from the factory. A few minutes with a screwdriver ensures the machine won’t vibrate itself apart during its first use. This is a critical safety and longevity step that is often overlooked.

When it comes to tension, be conservative. The manufacturing tolerances may not be as precise as on more expensive models. Start by tightening the knob until it stops, but then back it off a full two turns. It may not even cut at this setting. From there, turn the machine on and tighten the knob in tiny increments—an eighth of a turn at a time—until it begins to cut cleanly. With these shears, you must find the cutting point yourself rather than relying on a standard formula.

Premier 4000c: Mastering the Quick-Tension Knob

Premier’s 4000c shearer features a unique "quick-tension" knob, which can be a huge time-saver once you understand it. Instead of multiple turns, this system uses a lever and a notched knob for rapid adjustments. The initial setup, however, is still crucial. You first set the baseline tension using the traditional method: tighten the main nut until snug, then back off slightly.

The magic is in the quick-release lever. Once your baseline is set, this lever allows you to completely release the tension for cleaning or changing blades, then re-apply the exact same pressure instantly. This is fantastic for beginners who struggle to find the right tension again after a blade change.

To set it up, ignore the lever at first. Get the shears cutting perfectly by adjusting the main knob. Once you have it right, that’s your setting. Now, you can use the lever to release and re-engage. Do not use the lever to add more tension during shearing. It’s an on/off switch for your pre-set tension, not a tool for on-the-fly adjustments. Trying to force it will damage the mechanism and ruin your cut.

Oster ClipMaster: Setup for Crutching and Dagging

Many hobby farmers use the powerful Oster ClipMaster not for full shearing, but for the essential tasks of crutching (clearing wool from the rear) and dagging (removing dried manure). The setup for this is different because you’re dealing with dirty, often matted wool. You need blades designed for this, like a 20-tooth goat comb or a specialized dagging blade, which allows debris to pass through more easily than a fine shearing comb.

Tension for dagging needs to be slightly higher than for clean shearing. The grit and lanolin in dirty wool can force the cutter and comb apart, causing it to pull and jam. After setting your baseline tension (tighten, then back off 1.5 turns), you will likely need to add another quarter-turn of tension to power through the grime.

Because this is a dirty job, tool hygiene is paramount. You must stop and clean the blades with your brush far more often. Manure and dirt will build up, generating heat and dulling your blades in minutes if left unchecked. Keep your shearing oil handy and apply it generously; the grit acts like sandpaper, and oil is the only thing protecting your equipment.

Your electric shearer is a tool, and like any good tool, it performs best when it’s respected and understood. Taking the time to master its setup transforms shearing from a daunting chore into a skill. A well-tuned machine works with you, not against you, paving the way for a successful and far less stressful shearing season.