6 Trimmer Drive Shaft Maintenance That Prevent Common Issues

Avoid trimmer failure with proper drive shaft care. Our guide covers 6 key maintenance steps, including cleaning and lubrication, to ensure smooth operation.

You pull the cord, your string trimmer sputters to life, but something is wrong—a new, angry vibration rattles your hands and the cutting head seems sluggish. That’s often the first sign of trouble deep inside the tool, within the drive shaft system. Paying a little attention to this critical component is the difference between a reliable workhorse and a frustrating piece of junk.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Your Trimmer’s Drive Shaft System

The drive shaft is the spine of your trimmer. It’s a simple but vital part that transfers rotational power from the engine at one end to the cutting head at the other. Think of it as the driveshaft in a rear-wheel-drive truck, but smaller and spinning much, much faster.

Most trimmers use one of two types: a solid steel shaft or a flexible, wound-wire shaft. Solid shafts are rigid, offering direct power transfer and less vibration, but they can’t be used in curved-shaft models. Flexible shafts, common in those curved trimmers and many multi-tool systems, can bend but may introduce a bit of "lag" and are more prone to stretching or breaking under extreme load. Knowing which you have helps you understand how it might fail and what it should feel like when running properly.

Regularly Cleaning Debris from the Shaft Housing

It’s easy to focus on the engine and the cutting head, but the long tube connecting them needs attention, too. Grass, dirt, and moisture get packed around the bearing points and where the shaft enters the head. This gunk acts like an insulator, trapping heat and causing bearings to fail prematurely.

At the end of a long day of clearing fence lines, take 60 seconds with an air compressor or a stiff brush. Blow out any debris packed into the crevices of the trimmer head and around the shaft housing connections. This simple habit prevents grit from working its way into moving parts and stops corrosion before it starts. It’s one of the easiest ways to prevent the slow, grinding death of your tool.

Inflate tires quickly and easily with the DEWALT 20V MAX Inflator. It features automatic shutoff, an LED light, and three power source options for use at home or on the jobsite.

Visual Inspection for Bends, Cracks, and Wear

Before you even start the engine, give the trimmer a quick once-over. Lay it on a flat surface and sight down the shaft housing from the engine to the head. You’re looking for any obvious bends or dents, which can happen easily if the tool is dropped or gets jammed against a post.

A bent housing forces the internal drive shaft to flex and whip around as it spins, creating intense vibration. This doesn’t just make the tool uncomfortable to use; it rapidly destroys bearings and can eventually cause the shaft itself to snap. Also check the points where the shaft connects to the engine and the head assembly for any hairline cracks in the casting. Catching a slight bend or a tiny crack early can prevent a catastrophic failure mid-job.

Proper Greasing of the Drive Shaft Splines

The drive shaft doesn’t just float inside the housing; it connects to the engine and the gear head with splined ends. These are like little teeth that mesh together to transfer torque. Without proper lubrication, these splines will grind against each other, wearing down until they eventually strip out completely, leaving you with a running engine and a stationary trimmer head.

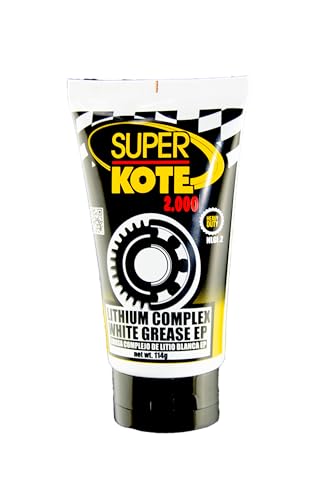

Every 20-30 hours of use, it’s wise to pull the shaft and grease the splines. On a straight shaft trimmer, this usually involves loosening a few screws to separate the power head from the shaft. For split-shaft models, you just disconnect the attachment. Pull the drive shaft out a few inches and apply a thin coat of high-temperature lithium grease to the splines on both ends. Don’t overdo it; too much grease can create hydraulic pressure and prevent the shaft from seating correctly. This single task is arguably the most important for ensuring a long service life.

Securing the Shaft Couplings and Connections

On trimmers with a two-piece or "split" shaft, the coupling in the middle is a common point of failure. The constant vibration of the engine works to loosen the clamping bolt over time. A loose connection creates slop, which amplifies vibration and puts immense stress on the internal drive shaft ends where they mate.

Before each major use, check that the main clamping knob or bolt is tight. It should be snug enough that you can’t twist the two halves of the housing by hand. If you notice the connection frequently loosens, it might be time to add a drop of blue (medium strength) thread-locker to the bolt threads. This ensures the connection stays solid without making it impossible to disassemble for maintenance or transport. A secure coupling means all the power goes to the cutting head, not into rattling the tool apart.

Correct Storage to Prevent Shaft Warping or Bends

How you store your trimmer matters more than you think. Leaning a long, straight-shaft trimmer in a corner for months can lead to a subtle, permanent bow in the aluminum housing. Likewise, hanging it by just the engine or just the trimmer head puts all the weight on one end, encouraging the shaft to sag over time.

The best practice is to store it horizontally on a rack with support at two or more points along its length. If you must hang it vertically, use a hook designed to hold it from a balanced point near the middle of the shaft. This prevents gravity from creating a bend that will introduce vibration the next time you fire it up. It’s a passive form of maintenance that costs nothing but protects your investment during the off-season.

Identifying Issues by Listening for New Vibrations

Your ears are one of your best diagnostic tools. A healthy trimmer has a consistent hum and vibration, but any new sound is a cry for help. A high-pitched squeal or whine that changes with RPM often points to a failing bearing in the gear head or where the shaft meets the clutch.

A harsh, grinding noise suggests a lack of grease or a piece of debris caught somewhere it shouldn’t be. A loud rattle could be as simple as a loose guard or as serious as a failing coupling. Don’t just ignore these new sounds and try to power through the job. Stop immediately and investigate. Tracing a sound to its source can help you catch a small problem, like a loose bolt or dry splines, before it becomes a big, expensive one.

Extending Trimmer Life with Proactive Maintenance

None of these maintenance steps are particularly time-consuming. In fact, you can perform all of them in about 15 minutes every month or so, depending on your usage. The tradeoff is simple: a few minutes of preventative care now versus hours of frustration and a costly repair bill later.

This isn’t about babying your equipment; it’s about respecting it as a critical tool for managing your property. A well-maintained trimmer starts easily, runs smoothly, and delivers its full power to the cutting line. By making these checks a routine part of your workflow, you ensure the tool is ready to work when you are, saving you time, money, and the headache of equipment failure on a busy weekend.

Ultimately, the longevity of your trimmer comes down to consistent, simple habits. Proactive maintenance keeps your tools running reliably, allowing you to focus on the work at hand, not on fixing what’s broken.