6 Best Corner Braces For Chicken Coop Construction for Harsh Weather

Protect your flock with a sturdy coop. We review the 6 best corner braces for harsh weather, comparing strength, materials, and corrosion resistance.

You step outside after a wicked storm to find your chicken coop leaning at a concerning angle, a corner joint splintered and failed. It’s a gut-wrenching feeling, knowing your flock was vulnerable while you were safe inside. A well-built coop is more than a house; it’s a fortress against wind, snow, and predators, and its strength comes from the connections holding it together. Choosing the right corner braces isn’t about over-engineering, it’s about ensuring that fortress stands strong when it matters most.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Your Coop Needs Heavy-Duty Corner Braces

A chicken coop isn’t just a box to keep birds in. It’s a small building that has to withstand real-world forces. Wind pushes against the walls, trying to rack the frame out of square. Heavy, wet snow pushes down on the roof, transferring immense weight to the corners.

This is where standard, flimsy little L-brackets from the hardware store bin fall short. They might hold a shelf, but they won’t resist the twisting and shearing forces of a 50-mph gust. Heavy-duty corner braces are made from thicker steel and are engineered to distribute those loads, preventing the wood from splitting and the screws from pulling out.

Think of it as cheap insurance. The small additional cost for a dozen high-quality braces is nothing compared to the cost and heartache of rebuilding a collapsed coop in the middle of winter. It’s the difference between a structure that lasts three years and one that lasts twenty, giving you peace of mind every time the weather turns nasty.

Simpson Strong-Tie L90: Reinforced Angle Bracket

When you need to know a connection will hold, you reach for a Simpson Strong-Tie. The L90 Reinforced Angle is a workhorse for any serious construction project, and it’s perfectly suited for locking down the critical corners of a chicken coop frame. It’s not just a bent piece of metal; it’s an engineered connector.

The key features are its G90 galvanized finish, which provides excellent protection against rust, and the distinctive reinforcing rib stamped into the corner. That small detail dramatically increases the bracket’s stiffness, preventing it from bending under load. Use these to connect your wall studs to the top and bottom plates or to secure the corners of your main floor frame.

While they cost more than generic brackets, you’re paying for documented load ratings and decades of structural engineering expertise. For the most critical 90-degree joints in your coop—the ones that bear the most weight and face the most stress—the L90 provides professional-grade strength that a simple stamped bracket can’t match.

National Hardware N221-827 Heavy-Duty Brace

Sometimes, the best solution is the one you can easily find at any local hardware store. The National Hardware heavy-duty corner brace is a perfect example of a widely available, no-nonsense connector that gets the job done. Its strength comes from sheer brute force: it’s made of thick, heavy-gauge steel.

This brace is ideal for general-purpose reinforcement where an engineered tie might be overkill. Think about reinforcing the frame for your coop door to prevent sagging or adding rigidity to the corners of nesting boxes. The zinc-plated finish offers decent weather resistance for most applications, especially if the brace is somewhat protected from direct rain.

It lacks the engineered stiffening ribs of a Simpson tie, so it’s not the top choice for holding up a heavy, snow-loaded roof. However, for adding immense strength to standard joints and preventing racking, its thickness and simplicity are a major advantage. It represents an excellent balance of cost, strength, and convenience.

OWT Post to Beam T-Brace: Maximum Shear Strength

Your coop’s primary frame, especially if it’s a larger walk-in design built with 4×4 posts, has unique stress points. The connection where a vertical post meets a horizontal beam is one of the most vulnerable. This is where a T-brace, specifically a heavy-duty one like those from OWT (Ornamental Wood Ties), becomes essential.

These braces are designed to handle massive shear and tension loads. The T-shape spreads the force across a wide area of both the post and the beam, preventing the wood from splitting under the weight of the roof. They are typically made from incredibly thick steel with a durable powder-coated finish, making them nearly impervious to weather.

Using an OWT T-Brace to connect your main posts to the floor frame or the top plates is a serious upgrade to your coop’s structural skeleton. It’s overkill for connecting 2x4s, but for the core 4×4 or 6×6 structure, it provides a level of stability that simple angle brackets can’t hope to achieve. This is how you ensure your coop’s core frame is immovable.

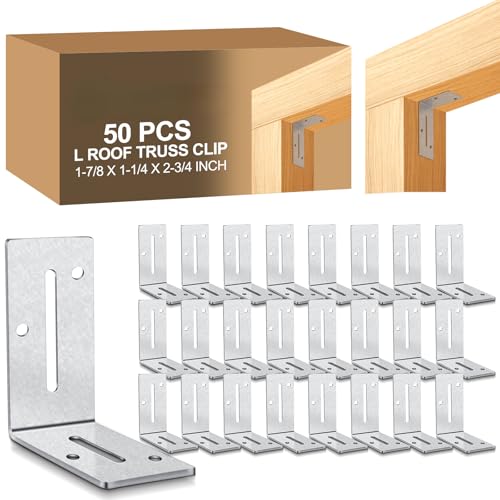

FastenMaster Truss Brace for 3-Way Connections

High winds don’t just push on walls; they try to lift the roof right off. The connection between your roof rafters and the top plate of your wall is a major failure point in DIY structures. The FastenMaster Truss Brace is a specialized piece of hardware designed specifically to combat this uplift force.

This connector solves the complex problem of joining three members together—the rafter, the ceiling joist, and the wall’s top plate. Its unique shape allows you to securely tie all three components into a single, unified joint. This prevents the roof from separating from the walls during a severe storm, which is often the first step in a catastrophic collapse.

You won’t use these on every corner. You use them at each point where a roof truss rests on the walls. Many coop plans simply call for toe-nailing rafters in place, which is woefully inadequate for high-wind areas. Investing in a set of proper truss braces is a critical, and often overlooked, step for building a truly storm-proof coop.

Stanley Hardware 316 Stainless Steel L-Brace

Reinforce right-angle joints with this 40-piece stainless steel L bracket set. Durable and easy to install, these brackets feature counterbore holes for a flush finish and include 80 screws for convenient use.

For most climates, galvanized steel is more than enough protection. But if you live in a coastal area with salt spray, a region with extreme humidity, or an area with acidic rain, even galvanized coatings can eventually fail. When absolute corrosion resistance is non-negotiable, you need stainless steel.

The Stanley Hardware 316 Stainless Steel L-Brace is the ultimate choice for longevity in harsh, wet environments. The "316" designation is key—it contains molybdenum, which gives it superior resistance to chlorides (like salt) and other forms of corrosion compared to more common stainless steels. These are perfect for the base of the coop frame where it might have contact with damp ground or for any connection constantly exposed to rain and runoff.

The tradeoff is, of course, the significant cost. You wouldn’t build an entire coop with these. But for the four or eight most vulnerable connections at the base of your structure, using 316 stainless steel braces ensures the foundation of your coop won’t be compromised by rust, even after a decade of exposure.

Everbilt Galvanized Steel Reinforced T-Brace

Not every T-joint in your coop carries the massive load of the roof. Many are there for intermediate support, like where a mid-wall stud meets the top or bottom plate. For these applications, the Everbilt Galvanized Steel Reinforced T-Brace is a practical and affordable solution.

Readily available at big-box stores, this brace is hot-dip galvanized for solid weather protection and provides excellent rigidity. It’s perfect for preventing long walls from bowing and for adding stiffness to internal dividers or the framing for a large run door. It stops the kind of flexing and wobbling that can weaken a structure over time.

Think of these as the supporting cast for your main structural connectors. While a heavy-duty post-to-beam connector holds the main frame, these Everbilt T-braces ensure the sections in between are just as solid. Sprinkling these throughout your coop’s frame is a cost-effective way to dramatically increase its overall stability without breaking the bank.

Choosing the Right Metal and Gauge for Your Climate

The "best" brace depends entirely on your specific weather threats. The first decision is the material and its finish. Zinc-plated is the bare minimum, suitable for dry climates or internal use. Hot-dip galvanized offers robust protection for most rainy and snowy regions. Powder-coating provides a thick, durable barrier, while stainless steel is the ultimate, albeit expensive, choice for coastal or perpetually damp areas.

Next, consider the steel gauge. This is crucial and often overlooked. A lower gauge number means thicker, stronger steel. A flimsy 20-gauge bracket is for decoration. For structural integrity in a coop facing harsh weather, you should be looking for 14-gauge at a minimum, and preferably 12-gauge or even thicker for primary connections.

Finally, match the brace to the force it needs to resist.

- Heavy Snow? Focus on T-braces and reinforced angle brackets with high shear strength at post-to-beam and roof-to-wall joints.

- High Winds? Prioritize truss braces for uplift resistance and use reinforced angle brackets everywhere to prevent racking.

- Constant Dampness? Strategically use galvanized or stainless steel braces at the base of the coop, even if the rest of the structure uses a lesser finish.

Don’t just buy the heaviest-duty brace for every single joint. Instead, analyze your design, identify the most critical stress points, and invest in the right piece of hardware for that specific job. A smart combination of different braces is far more effective and economical than a one-size-fits-all approach.

Ultimately, the hardware holding your coop together is a tiny fraction of its total cost, but it’s responsible for a huge part of its strength and longevity. By thinking like a builder and choosing the right brace for the right job, you’re not just screwing pieces of wood together. You’re making a long-term investment in the safety of your flock and your own peace of mind.