6 Best Goat Trailer Fenders For Small Farms That Withstand Rough Pastures

Rough pastures demand durable goat trailer fenders. Our guide reviews the top 6 options, ensuring your trailer and livestock are protected on rugged terrain.

You’ve just navigated a tight gate, backed your goat trailer through a muddy patch, and heard that awful sound—the crunch of a fender against a fence post. Standard trailer fenders are built for smooth pavement, not the realities of a working farm. Choosing the right replacement isn’t just about looks; it’s about investing in durability that saves you time, money, and frustration down the road.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Standard Fenders Fail on Rough Farm Terrain

The flimsy, rolled-edge fenders that come on most small utility trailers are designed for one thing: deflecting road spray on a highway. They simply aren’t engineered for the torsional stress of crossing uneven ground. As your trailer frame twists going over ruts and bumps, these weak fenders flex until they crack at the mounting points.

It’s not just about twisting, either. Think about the hazards unique to a farm. A misjudged turn can easily press a fender into a T-post, a tree, or the corner of a barn. A standard fender will crumple like aluminum foil. Add in the constant barrage of gravel from your truck tires and the corrosive effects of mud and manure, and their short lifespan becomes predictable.

A farm-tough fender needs to do more than just cover the tire. It needs to be a piece of armor. It should be strong enough to take an accidental hit without collapsing and be made of a material that won’t rust away after one wet season. This isn’t an aesthetic upgrade; it’s a functional necessity for equipment that has to earn its keep.

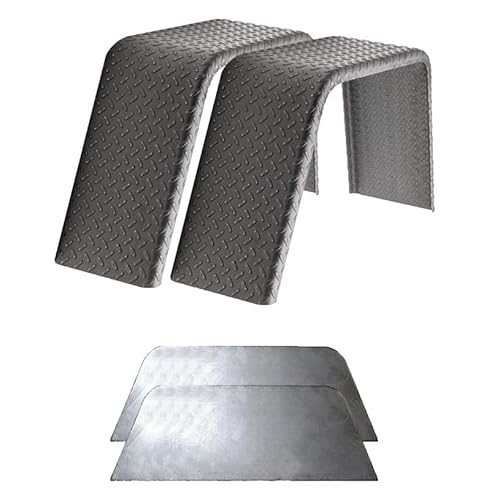

Buyers Products Diamond Tread Steel Fender

When pure, brute strength is what you need, a heavy-gauge diamond tread steel fender is the obvious choice. The raised diamond pattern isn’t just for looks; it adds significant rigidity to the steel, helping it resist bending and denting from impacts. This is the fender you want when you know you’ll be bumping into things.

Think of it as your first line of defense. If you’re hauling feed through a tight, wooded trail or backing up next to rock piles, this fender can take a serious knock and just get a scratch. Its steel construction means it can handle the weight if you need to use it as a quick step to check on the animals inside.

The major tradeoff, of course, is rust. Even with a good powder coat, a deep scratch will expose the raw steel to the elements. If you choose steel, be prepared for occasional maintenance. A quick sanding and a shot of rust-inhibiting paint once a year will dramatically extend its life, making it a reliable workhorse for years.

Extreme Max Poly Fender for All-Weather Use

If your biggest enemy is moisture, a high-density polyethylene (or "poly") fender is a fantastic solution. These fenders are completely immune to rust and corrosion, making them ideal for farms in wet, humid climates or for those who frequently haul through mud and muck. They laugh at the corrosive nature of manure.

The real magic of a good poly fender is its flexibility. Unlike steel that dents or aluminum that tears, a poly fender can absorb a surprising amount of impact and pop right back into shape. This is perfect for those minor bumps against gate posts or feed troughs that happen to everyone. They are also significantly lighter than steel, which can be a small but welcome benefit for towing.

However, not all plastics are created equal. Cheaper versions can become brittle in extreme cold and shatter on impact, so investing in a quality brand is crucial. While they resist blunt force well, a sharp, direct impact from something like a steel T-post could still puncture or crack them. They offer a different kind of durability than steel—one based on resilience rather than rigidity.

Triton Smooth Aluminum Fender for Tandem Axles

For those with a slightly larger trailer, perhaps a tandem axle model for hauling a small herd to a new pasture or to market, aluminum fenders offer a compelling balance. Their primary advantage is being extremely lightweight and completely rust-proof. This reduces your trailer’s overall weight and ensures it won’t be weakened by corrosion over time.

The smooth finish on a fender like this is more practical than you might think. Mud and manure wash off incredibly easily, making cleanup after a messy haul much faster. This is a bigger deal than it sounds when you’re trying to get chores done before dark.

The downside to aluminum is its relative softness compared to steel. It will resist dents better than a cheap stock fender, but a hard impact that would only scratch a steel fender might leave a significant dent or even a tear in an aluminum one. It’s a great choice for farms with open pastures and less risk of tight, damaging encounters, where corrosion resistance and ease of cleaning are the top priorities.

Karavan Weld-On Steel Jeep Style Fender

The "Jeep style" fender is defined by its flat top and angular, rugged design. This isn’t just about aesthetics; that flat top creates a highly functional step or a temporary shelf for a tool or a bucket of feed. For a working trailer, this added utility is a significant advantage.

This fender’s key feature is its "weld-on" design. Unlike bolt-on fenders that can rattle loose or have their mounting points fail under stress, a welded fender becomes an integral part of the trailer frame. This provides the absolute maximum in strength and durability. Once it’s on, it’s not going anywhere.

The obvious consideration is that you need the equipment and skill to weld it on, or you’ll have to pay someone to do it. This makes installation more involved than a simple bolt-on replacement. However, for a farmer building a trailer from scratch or completely overhauling an old one, welding on a set of these heavy-duty fenders creates a piece of equipment you know you can rely on for decades.

C.E. Smith Steel Fender with Integrated Back

One of the most annoying parts of hauling on a farm is the sheer amount of mud, rocks, and manure that gets flung everywhere by the trailer tires. It cakes onto the trailer’s frame, gets into the suspension, and can even be thrown forward onto your truck. A fender with an integrated back plate directly addresses this problem.

This design features a vertical steel plate on the inside of the fender, effectively boxing it in. This backing contains the debris, protecting your trailer’s siding and undercarriage. It’s a small design choice with a big impact on cleanliness and the long-term preservation of your trailer’s frame.

The tradeoff is that this enclosed design can also trap moisture and mud if not cleaned out regularly. In very wet climates, you’ll want to make a point of hosing out the inside of the fender to prevent mud from sitting against the frame and causing rust. For most, however, the protection it offers is well worth the occasional rinse.

Tuff Fender Unbreakable Molded Plastic Fender

For the farmer who is just plain tired of replacing broken fenders, the "unbreakable" plastic fender is the answer. These are typically made from a specialized, rotationally molded polymer that is designed to deform under extreme impact and then return to its original shape. They are built to take an absolute beating.

Imagine backing into a tree stump—a steel fender would be permanently mangled, and a standard plastic one would likely shatter. An unbreakable fender will bend, absorb the force, and pop back out, maybe with a scuff mark as the only evidence. This is the ultimate "set it and forget it" option for durability.

These fenders carry a higher price tag than other poly options, but the cost can be easily justified if you’ve already replaced two or three cheaper fenders. They represent a long-term investment in peace of mind. You simply stop worrying about fender damage and focus on the work at hand.

Matching Fender Material to Your Farm’s Needs

There is no single "best" fender; there is only the best fender for your specific situation. The right choice depends on your climate, your terrain, and how you use your trailer. Thinking through these factors will lead you to the most practical and cost-effective decision.

Start by assessing your primary challenge. Is it constant mud and moisture, or is it the risk of high-impact collisions with rocks and trees? Your answer points you toward a material.

- Steel: Best for high-impact durability. Choose steel if your trailer navigates rocky terrain, tight wooded areas, or is frequently used by people who are hard on equipment. Be prepared for rust prevention.

- Plastic/Poly: Best for all-weather resilience. Choose a poly fender if you operate in a wet, muddy climate where rust is your biggest enemy. Excellent for absorbing minor bumps and scrapes.

- Aluminum: Best for lightweight, corrosion-proof utility. Choose aluminum when reducing trailer weight is a concern and your paths are relatively clear of major impact hazards. It’s a great balance for clean, open-pasture operations.

Ultimately, your trailer fender is a tool. A diamond plate steel fender is a hammer—strong, simple, and effective. A flexible poly fender is a rubber mallet—resilient and forgiving. Choose the right tool for the job you’re asking it to do.

Upgrading your trailer fenders from a cheap replacement to a deliberate choice for your farm’s environment is a small change that pays off every time you haul. It eliminates one more potential point of failure, letting you focus on the goats in the trailer, not the equipment carrying them. That’s a trade worth making any day of the week.