6 Best Pond Aerator Motor Repair Kits For Cold Climates to Prevent Winter Kill

Ensure your pond survives the freeze. This guide reviews the 6 best aerator motor repair kits for cold climates, crucial for preventing winter kill.

There’s a specific kind of quiet that falls over a farm when the first hard freeze sets in, and it’s a quiet that can make a pond owner nervous. That silence is broken only by the hum of your aerator, the one thing standing between your fish and winter kill. When that hum turns into a grind, or worse, stops altogether in the dead of January, you have a serious problem on your hands.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Winter Aerator Repair is Crucial for Fish

Winter kill happens when a pond freezes over completely. The solid sheet of ice prevents the natural exchange of gasses, trapping harmful ones like ammonia and methane from decaying matter below while blocking fresh oxygen from entering the water. As oxygen levels plummet, fish suffocate. It’s a slow, silent death that can wipe out your entire stock by the time the spring thaw arrives.

An aerator is your primary defense. It works by bubbling warmer water from the bottom of the pond up to the surface, creating a constant, open hole in the ice. This small opening is a vital lifeline, allowing toxic gasses to escape and oxygen to dissolve into the water. The system is simple, but its effectiveness hinges entirely on the motor or compressor that drives it.

This is why proactive repair is non-negotiable in cold climates. A motor failure in July is an inconvenience; a failure in January is a catastrophe. Performing a pre-winter rebuild with a proper kit is far cheaper than replacing a whole unit mid-crisis and infinitely less heartbreaking than discovering a dead pond in April. It’s about replacing wearable parts like bearings, seals, and diaphragms on your schedule, not on winter’s.

Kasco Marine Universal Motor Rebuild Kit

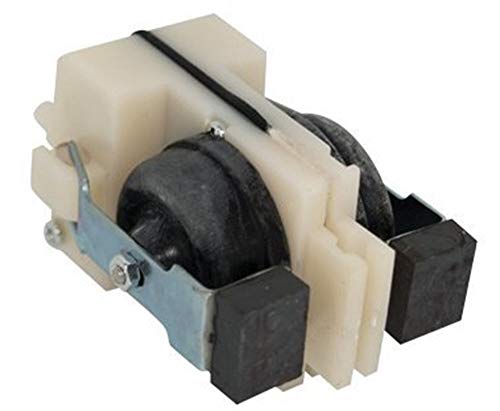

When you have a serious piece of equipment like a Kasco aerator, you don’t just patch it; you rebuild it. These units are workhorses, designed to run for thousands of hours, and their rebuild kits reflect that philosophy. A typical Kasco kit isn’t just a single part—it’s a comprehensive set of new bearings, shaft seals, and all the necessary O-rings to put it back together properly.

This is the kit you turn to when your older unit starts sounding rough or develops a slight vibration. That noise is often the first sign of bearing wear. Ignoring it can lead to catastrophic failure where the motor seizes completely. The rebuild process is more involved than some other kits, requiring you to disassemble the motor housing, but the result is a unit that runs as well as it did on day one.

Think of this as a long-term investment. You’re not just fixing a problem; you’re extending the life of an expensive, high-quality motor for several more seasons. For a submerged motor that has to endure the brutal conditions of a frozen pond, ensuring its internal components are fresh and its seals are perfect is the best insurance you can buy.

Airmax EcoSeries Motor Maintenance Kit for Ponds

Airmax systems, especially their shore-based cabinet aerators, are incredibly popular on hobby farms, and for good reason. They are reliable and easy to maintain, and their maintenance kits are a perfect example of this. These kits are designed for routine service to keep the system at peak performance, not for a last-ditch emergency repair.

The heart of an Airmax compressor is its diaphragms, the flexible membranes that pulse to pump air. Over a year or two of constant operation, they can stretch and develop tiny tears, leading to a noticeable drop in air output. The maintenance kit provides new diaphragms, airline filters, and check valves—all the common wear items. The repair is straightforward and can usually be done in under an hour with basic tools.

This kit is all about preventative care. You use it in the fall, even if the system seems to be running fine. By replacing the diaphragms before they fail, you ensure your diffusers will be bubbling vigorously when the ice is thickest. It’s a simple task that prevents the slow decline in aeration efficiency that can sneak up on you and put your fish at risk.

Scott Aerator Sub-Zero Motor Gasket & Seal Kit

Scott Aerators are often recognized for their high-volume water movement, making them excellent de-icers. Their motors are built to withstand the immense pressure and stress of operating in freezing water. The biggest threat to these submerged units isn’t necessarily bearing wear, but water intrusion.

A Sub-Zero Motor Gasket & Seal Kit is designed specifically to combat this threat. Even a microscopic breach in a seal can be fatal in winter. Water seeps in, freezes, expands, and can crack the motor housing or short out the electrical components. This kit provides all the precision-cut gaskets and heavy-duty shaft seals needed to make the motor housing completely watertight.

You’d use this kit every few years, or if you ever have to take the unit out for another repair. It’s a "while you’re in there" job that is absolutely critical. It’s less about fixing a running problem and more about hardening the unit against the most insidious winter threat. For anyone relying on a submerged motor to keep a hole open in the ice, a perfect seal is everything.

EasyPro PA-Series Compressor Rebuild Kit

Many pond aeration systems rely on a shore-mounted piston compressor, and the EasyPro PA-Series are common workhorses. Unlike a diaphragm pump, these units use a piston moving within a cylinder to compress air. Over time, the piston cup—a flexible ring that creates the seal—wears down. When it does, the compressor runs, but its pressure output plummets.

An EasyPro rebuild kit directly addresses this specific failure mode. The kit typically includes a new piston cup, a cylinder sleeve, and the required gaskets. This is a true rebuild that restores the compressor’s ability to push air through long lengths of tubing to diffusers sitting in deep water. If your bubbles have gotten weak, a worn piston cup is the most likely culprit.

This repair is a bit more mechanical than swapping a diaphragm but is well within the reach of a handy farm owner. It brings a weak, ineffective compressor back to factory specifications. In a cold climate, a compressor that can’t overcome the back pressure of deep, cold water isn’t doing its job, making this rebuild essential for winter survival.

Aquascape Pro Air 60 Diaphragm Repair Kit

Aquascape is a huge name in water gardens, but their professional-grade aerators are robust enough for farm ponds. Their Pro Air 60, a linear diaphragm pump, is a popular model. Its most common point of failure is, predictably, the diaphragms. When they tear, air output drops to almost nothing, even though you can still hear the unit humming.

The repair kit for this unit is brilliantly simple. It contains the two diaphragm blocks that generate the airflow. What makes it unique is the inclusion of a small safety screw. This screw is designed to snap intentionally if a diaphragm fails, which stops the motor’s moving parts from smashing around and destroying the whole unit. It is crucial to replace this screw when you replace the diaphragms.

This is a perfect example of a targeted, user-friendly repair. The kit gives you exactly what you need to fix the most common problem and includes the safety feature to ensure a lasting repair. It turns a potentially dead pump into a fully functional unit in about 15 minutes, which is exactly what you need when you’re racing against a cold front.

TundraFlow Arctic-Duty Motor Bearing Kit

Sometimes, you have an older, off-brand aerator motor that has served you well, but you can’t find a specific OEM kit for it. Or maybe you’re just the type who prefers to fix the core problem yourself. This is where a more generic, component-level kit like an arctic-duty bearing kit comes into play. "TundraFlow" might be a fictional name, but the concept is very real.

These kits don’t contain brand-specific housing gaskets, but they provide the most critical components: high-quality, sealed motor bearings rated for low-temperature operation. A standard bearing’s grease can thicken in extreme cold, leading to strain and premature failure. Arctic-duty bearings use a synthetic grease that stays viscous, ensuring smooth operation even on the coldest nights.

Choosing this path requires more skill. You’ll need to know how to pull the old bearings off the motor shaft and press the new ones on without damaging them. However, for a motor that is electrically sound but screaming with worn bearings, this is the most economical repair possible. It saves a perfectly good motor from the scrap heap and equips it with components that are superior to the originals for winter use.

Choosing a Repair Kit for Your Aerator System

The "best" repair kit has nothing to do with brand names and everything to do with your specific situation. Making the right choice comes down to answering three simple questions honestly. Get this right, and your pond will be in good shape.

First, what is the symptom? A loud grinding or whining noise points directly to bearings (Kasco, TundraFlow). A significant drop in airflow from a running compressor suggests worn diaphragms or pistons (Airmax, Aquascape, EasyPro). If you’re just doing preventative maintenance on a submerged motor, your focus should be on waterproofing (Scott Aerator). Match the kit to the problem.

Second, what type of system do you have? A submerged motor and a shore-based compressor are two completely different machines. A diaphragm kit is useless for a piston compressor, and a motor seal kit won’t help a cabinet aerator. Identify your equipment first, then look for the corresponding kit.

Finally, what is your mechanical skill level? Be realistic. Swapping a diaphragm on an Airmax or Aquascape unit is a quick, simple job. A full motor rebuild on a Kasco or a bearing replacement on an older motor requires more tools and confidence. Choosing a job that’s beyond your comfort level can lead to a broken aerator and a much bigger bill. The best repair is the one you can complete successfully before the ice sets in.

Ultimately, a pond aerator motor is a simple machine doing a critical job. A small box of seals, bearings, or diaphragms, bought and installed in the calm of autumn, is the cheapest insurance policy you can get. It ensures that the steady hum of your aerator continues through the harshest winter nights, protecting the life you’ve nurtured beneath the ice.