7 Ways to Develop a Local Ingredient Sourcing Guide That Supports Your Community

Discover how to create a comprehensive local ingredient sourcing guide to enhance food quality, support local economies, and build sustainable relationships with regional producers.

Creating a local ingredient sourcing guide is a game-changer for restaurants, home cooks, and sustainability champions looking to support their community’s food ecosystem. You’ll not only strengthen relationships with local farmers and producers but also gain access to fresher, more unique ingredients that can differentiate your culinary offerings.

Developing this valuable resource requires strategic planning, relationship building, and thorough documentation—but the benefits of seasonal cooking, reduced carbon footprint, and storytelling opportunities make it well worth the effort. When you connect directly with local sources, you’re investing in your community’s economic health while creating transparent food systems that customers increasingly demand.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding the Benefits of a Local Ingredient Sourcing Guide

Enhanced Food Quality and Flavor

A local ingredient sourcing guide connects you directly to the freshest ingredients available in your area. When produce travels shorter distances, it’s harvested closer to peak ripeness, resulting in superior flavor profiles and nutritional content. Fresh herbs picked this morning will always outperform those shipped across the country three days ago. Local varieties often include heritage or heirloom options that offer unique tastes and textures you simply can’t find in mass-produced alternatives.

Strengthened Local Economy

Redirecting your purchasing power to local producers creates a meaningful economic impact in your community. Every dollar spent with local farmers generates approximately 2-3 times more economic activity than purchases from larger corporate suppliers. Your consistent business helps small-scale producers maintain stable operations, create jobs, and reinvest in regional agricultural infrastructure. This economic reinforcement builds a more resilient local food system that benefits everyone.

Environmental Sustainability

Sourcing ingredients locally dramatically reduces the carbon footprint of your food supply chain. The average food item in America travels about 1,500 miles from farm to plate, while locally sourced ingredients might travel just 50 miles or less. This transportation difference alone cuts fossil fuel consumption and emissions significantly. Local producers are also more likely to implement sustainable growing practices like crop rotation, integrated pest management, and water conservation techniques that protect the surrounding ecosystem.

Seasonal Connection and Menu Innovation

A local sourcing guide naturally aligns your kitchen with seasonal rhythms, encouraging creativity and menu innovation. Working with what’s currently available pushes you to develop new recipes and techniques rather than relying on the same ingredients year-round. This seasonal approach creates natural menu refreshes that excite customers and prevent culinary stagnation. The limitations of seasonality actually foster greater creativity and distinctive offerings that set you apart from competitors using standardized ingredients.

Setting Clear Goals and Objectives for Your Sourcing Guide

Identifying Your Business Needs

Before creating your local ingredient sourcing guide, you’ll need to assess your specific requirements. Start by evaluating your menu or recipes to determine which ingredients you use most frequently. Consider your volume needs, budget constraints, and quality standards that align with your brand identity. Identify gaps in your current sourcing system that local producers could fill, such as specialty items that would enhance your offerings or ingredients that could benefit from fresher local alternatives.

Establishing Sustainability Criteria

Develop clear sustainability benchmarks that potential suppliers must meet to be included in your guide. Focus on farming practices like organic certification, regenerative agriculture methods, or chemical-free growing. Consider transportation distance (typically under 100 miles for “local” designation) and packaging requirements that minimize environmental impact. Create a simple scoring system that evaluates potential suppliers against your sustainability priorities, making selection decisions more consistent and defensible.

Researching Available Local Ingredients in Your Region

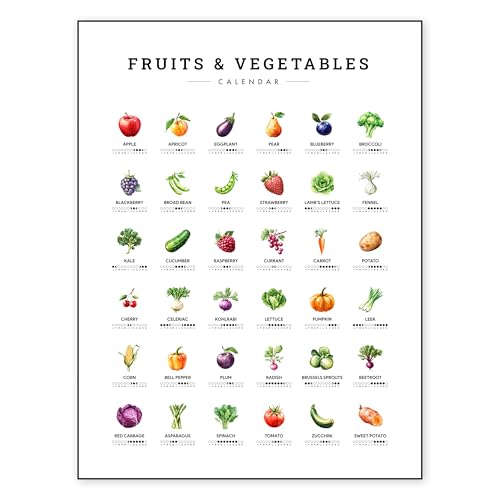

Creating a Seasonal Availability Calendar

To build an effective seasonal availability calendar, start by identifying which crops grow in your region throughout the year. Document harvest periods for fruits, vegetables, grains, and specialty items like mushrooms or honey. Consult with local agricultural extensions, farmers’ markets, and experienced gardeners to verify growing seasons. Create a visual matrix organizing ingredients by month, making it easy to plan menus and purchasing strategies around peak availability windows.

Mapping Potential Suppliers Within Your Area

Begin mapping suppliers by defining your “local” radius—typically 100-150 miles, though this varies by region and urban density. Use online directories like LocalHarvest.org or USDA’s farmers market database to identify farms, producers, and food hubs. Create a comprehensive spreadsheet categorizing suppliers by product type, location, and distance from your establishment. Include contact information, delivery capabilities, and minimum order requirements to streamline future outreach efforts.

Building Relationships With Local Farmers and Producers

Establishing Communication Channels

Building strong relationships with local producers starts with effective communication channels. Begin by attending farmers’ markets and agricultural events where you can meet farmers face-to-face. Create a database with contact information including phone numbers, email addresses, and social media handles for consistent outreach. Schedule regular check-ins—monthly calls or quarterly farm visits—to maintain connections and stay informed about upcoming harvests and availability.

Negotiating Terms and Pricing Structures

When negotiating with local suppliers, approach conversations as partnerships rather than transactions. Discuss volume-based discounts, where purchasing larger quantities can reduce per-unit costs. Establish flexible payment terms that work for both parties—some farmers might prefer immediate payment while others can accommodate net-30 arrangements. Create multi-season contracts that guarantee purchases, offering farmers stability while securing your access to premium local ingredients.

Evaluating Quality Standards and Certification Requirements

Organic and Sustainable Certifications

When developing your local sourcing guide, identify which certifications matter most to your operation. USDA Organic, Certified Naturally Grown, and Regenerative Organic Certified each verify different environmental practices. Document certification requirements in your guide, noting that some smaller farms use organic methods without formal certification due to cost barriers. Compare certification standards against your sustainability goals to determine which align best with your values and customer expectations.

Implementing Quality Control Processes

Establish clear quality benchmarks for each ingredient type to maintain consistency across suppliers. Create a simple inspection checklist covering appearance, size, freshness, and flavor profiles for staff to use upon delivery. Implement a scoring system (1-5) for objective evaluation of incoming products, and document all quality issues with photos for supplier feedback. Schedule regular quality review meetings with your team to refine standards based on seasonal variations and customer feedback.

Creating a Detailed Supplier Database

Documenting Contact Information and Specialties

Organize your supplier information in a comprehensive database that’s easy to update and reference. Include each supplier’s name, primary contact person, phone number, email, physical address, website, and social media handles. Document their product specialties, growing methods, peak seasons, delivery options, and minimum order requirements to streamline your ordering process and quickly identify the right supplier for specific ingredients.

Setting Up a Supplier Rating System

Develop a quantifiable rating system to evaluate supplier performance consistently. Create categories such as product quality (1-5), reliability (1-5), communication (1-5), and price point (1-5), allowing you to track performance over time. Include notes about exceptional products, delivery issues, or special accommodations to help inform future purchasing decisions. Review these ratings quarterly to identify your strongest partnerships and areas where alternative suppliers might be needed.

Developing a Contingency Plan for Supply Disruptions

Identifying Alternative Sources

Always maintain a list of backup suppliers for your essential ingredients to protect against disruptions. Research farms and producers beyond your primary network, including those slightly outside your defined local radius. Develop relationships with these alternative sources before you need them, understanding their production capabilities and delivery options. Consider forming mutual aid agreements with other restaurants or food businesses to share supplier contacts during shortages or emergencies.

Creating Buffer Inventory Strategies

Implement strategic inventory management to cushion against supply chain disruptions. Identify shelf-stable local items that can be purchased in bulk during peak season and preserved through freezing, canning, or dehydrating. Calculate minimum buffer stock levels for critical ingredients based on usage rates and supplier lead times. Create dedicated storage systems for these buffer ingredients, with clear rotation protocols to maintain freshness and minimize waste during normal operations.

Establishing a Cost Analysis Framework

Understanding the financial implications of local sourcing requires a structured approach to cost analysis. This framework will help you make informed decisions based on comprehensive cost comparisons.

Comparing Local vs. Non-Local Pricing

Local ingredients often carry premium price tags compared to conventional wholesale options. Track both pricing structures side-by-side in a spreadsheet for each key ingredient. Consider seasonal fluctuations when smaller local farms offer competitive pricing during peak harvest periods. Remember that higher quality local items may command better menu prices, potentially offsetting initial cost differences.

Calculating True Cost Including Transportation

The true cost of ingredients extends beyond the purchase price. Factor in delivery fees, fuel costs for pickup trips, and staff time required for sourcing activities. Create a mileage-based calculation for self-pickup scenarios. Consider the environmental cost of transportation through carbon footprint measurements. Some local suppliers may offer consolidated delivery options that reduce these auxiliary expenses substantially.

Factoring in Seasonality Effects on Pricing

Pricing dynamics shift dramatically with seasons. Create a seasonal pricing calendar tracking how local ingredient costs fluctuate throughout the year. Identify strategic buying periods when local prices drop below non-local alternatives. Develop preservation strategies for peak-season purchasing when prices hit annual lows. This seasonal awareness allows you to lock in favorable prices through preservation or processing techniques.

Assessing Volume Discount Opportunities

Volume purchasing creates significant savings opportunities with local suppliers. Negotiate tiered pricing structures based on consistent weekly or monthly commitments. Consider coordinating with other businesses for collective purchasing power. Document minimum order thresholds for various suppliers and plan accordingly. These volume agreements often strengthen supplier relationships while reducing per-unit costs.

Developing Long-Term Cost Projection Models

Project ingredient costs over 6-12 month periods to improve budgeting accuracy. Account for seasonal availability when creating financial forecasts. Build inflation factors into your projections based on historical agricultural trends. Create multiple scenarios to prepare for potential supply disruptions or climate impacts. These projections help stabilize menu pricing and protect profit margins despite fluctuating ingredient costs.

Designing Your Sourcing Guide Document

Organizing Information for Easy Reference

Create a logical structure for your sourcing guide with clear sections and subsections for quick navigation. Group suppliers by product categories (produce, dairy, proteins) and arrange each entry alphabetically or by distance from your location. Include a comprehensive index and tabbed dividers for physical guides to enable staff to locate specific ingredients or suppliers instantly, even during busy service periods.

Creating User-Friendly Visual Elements

Incorporate color-coding to distinguish between different product categories or seasonal availability. Design simple icons to represent certification types, delivery schedules, and minimum order requirements. Create visual calendars showing harvest timelines for key ingredients using graphs or charts. Consider adding QR codes linking to supplier websites or digital maps showing farm locations to enhance functionality while maintaining a clean, uncluttered design.

Implementing Your Local Sourcing Strategy

Training Your Team on Guide Usage

Create a comprehensive training program that familiarizes your staff with the sourcing guide’s structure and purpose. Schedule hands-on workshops where employees practice navigating the guide to locate seasonal ingredients and contact suppliers. Assign guide champions within your team who can answer questions and reinforce proper usage. Develop quick-reference cards that highlight the most frequently needed information for daily operations.

Monitoring and Measuring Success

Track key performance indicators including percentage of locally sourced ingredients, cost comparisons with previous suppliers, and customer feedback on menu items featuring local products. Document delivery reliability, product quality consistency, and seasonal availability accuracy within your guide. Review these metrics quarterly to identify successful partnerships and areas needing improvement. Calculate environmental impact by measuring reduced food miles and supporting regenerative farming practices.

Maintaining and Updating Your Sourcing Guide

Your local ingredient sourcing guide isn’t just a document—it’s a living resource that evolves with your business and community. By implementing the strategies outlined in this guide you’ve created a powerful tool that connects your kitchen to local farmers strengthens your community and enhances your culinary offerings.

Remember that regular updates are essential as seasons change suppliers evolve and your needs shift. Schedule quarterly reviews to refresh information and reassess your supplier relationships. The time you invest in maintaining this guide will pay dividends through fresher ingredients reduced environmental impact and meaningful local connections.

Ready to transform your sourcing practices? Start small focus on a few key ingredients and watch as your local food network grows organically alongside your business success.

Frequently Asked Questions

What is a local ingredient sourcing guide?

A local ingredient sourcing guide is a comprehensive resource that helps restaurants, home cooks, and food businesses identify, evaluate, and connect with local farmers and producers. It typically includes information about seasonal availability of ingredients, supplier contact details, certification standards, and pricing structures—all organized to make local sourcing more systematic and sustainable.

Why is local ingredient sourcing important for restaurants?

Local sourcing provides fresher, higher-quality ingredients with better flavor profiles. It reduces the carbon footprint of food supply chains, supports the local economy (generating up to 3 times more economic activity than non-local purchasing), builds community connections, and creates compelling stories that differentiate restaurants in competitive markets. Customers increasingly value transparency and sustainability in food sourcing.

How do I identify which ingredients to source locally?

Start by evaluating your menu to identify frequently used ingredients. Assess your volume needs, budget constraints, and quality standards for each item. Then research which ingredients grow in your region and create a seasonal availability calendar. Focus first on high-volume items or signature ingredients where local sourcing would make the biggest impact.

What information should I include in my supplier database?

Your supplier database should include contact information, product specialties, growing methods, certifications, peak seasons, delivery schedules, minimum order requirements, pricing structures, and payment terms. Also document your history with each supplier and maintain a performance rating system tracking quality, reliability, communication, and price consistency.

How do I create a seasonal availability calendar?

Research crops that grow in your region throughout the year and document their harvest periods. Consult agricultural extension offices, local farming associations, and experienced farmers. Create a visual matrix organizing ingredients by month, noting peak seasons and shoulder seasons. Update this calendar annually as farming practices and climate conditions evolve.

How can I build strong relationships with local farmers?

Attend farmers’ markets and agricultural events to meet producers face-to-face. Establish consistent communication channels and schedule regular check-ins through monthly calls or quarterly farm visits. Negotiate fair, mutually beneficial terms that may include volume discounts and flexible payment structures. Consider multi-season contracts to provide stability for both parties.

What certifications should I look for from local suppliers?

Consider which certifications align with your sustainability goals, such as USDA Organic, Certified Naturally Grown, Animal Welfare Approved, or Fair Trade. Remember that smaller farms may use organic methods without formal certification due to cost barriers. Develop your own criteria for evaluating sustainable practices if certification isn’t available from all suppliers.

How do I handle supply disruptions when sourcing locally?

Maintain a list of backup suppliers for essential ingredients and build relationships with alternative sources. Implement buffer inventory strategies by calculating minimum stock levels based on usage rates and identifying shelf-stable local items that can be preserved. Consider processing and preserving seasonal ingredients during peak availability to extend their usability.

Is local sourcing more expensive than conventional sourcing?

Local sourcing can sometimes involve higher direct costs, but a comprehensive cost analysis should consider all factors. Calculate true costs including transportation, storage needs, reduced waste from fresher products, and potential premium pricing opportunities for customers. Negotiate volume discounts and develop long-term relationships to stabilize costs over time.

How do I implement a local sourcing guide with my staff?

Create a comprehensive training program that familiarizes staff with the guide’s structure and usage. Conduct hands-on workshops, assign guide champions within your team, and develop quick-reference materials for daily operations. Schedule regular updates and refresher sessions, especially during seasonal transitions, to keep everyone informed about available ingredients.