6 Best Brewing Fermentation Heaters for Small Batch Beer That Work

Discover the 6 best fermentation heaters for small batch brewing. From budget-friendly options to premium systems, find the perfect temperature control solution for consistent, professional-quality beer at home.

Why it matters: Maintaining consistent fermentation temperature is crucial for brewing quality beer at home — too cold and your yeast becomes sluggish, too hot and you’ll get unwanted flavors that ruin your batch.

The challenge: Most home environments don’t naturally provide the ideal 65-75°F range that beer yeast needs to work its magic, especially during colder months or in basements where many brewers set up shop.

What we found: After researching dozens of heating solutions, we’ve identified six fermentation heaters that’ll keep your small batches at perfect temperatures without breaking the bank or overwhelming your brewing setup.

|

$39.54

|

$17.00

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Fermentation Temperature Control for Small Batch Brewing

Mastering temperature control transforms your brewing from hit-or-miss to consistently excellent. You’ll discover how precise thermal management impacts every aspect of your fermentation process.

Why Temperature Matters in Beer Fermentation

Temperature directly controls yeast activity and metabolic byproduct formation during fermentation. When temperatures exceed 78°F, you’ll get aggressive yeast behavior producing harsh fusel alcohols and unwanted esters that create off-flavors. Cold temperatures below 60°F slow yeast activity dramatically, potentially causing stuck fermentation or unfinished beer with residual sweetness.

Ideal Temperature Ranges for Different Beer Styles

Ales ferment best between 65-72°F, with IPAs and wheat beers tolerating slightly higher temperatures around 75°F. Lagers require cooler conditions at 50-55°F for clean, crisp profiles that showcase malt character. Belgian styles perform well at 72-78°F where controlled ester production creates their signature fruity complexity without harsh alcohol notes.

Common Temperature Control Challenges for Home Brewers

Basement breweries experience 15-20°F temperature swings between seasons, making consistent fermentation nearly impossible without heating assistance. Apartment brewing faces space constraints and noise concerns that limit heating equipment options. Winter brewing often requires continuous heating for 7-14 days, while summer conditions may need cooling solutions to prevent overheating during active fermentation phases.

Essential Features to Look for in Brewing Fermentation Heaters

Choosing the right fermentation heater requires understanding your specific brewing setup and temperature needs. The best heater balances consistent warmth with safety and compatibility for your fermentation vessels.

Wattage and Heating Capacity Requirements

Most small batch brewing requires 15-25 watts for 5-gallon fermenters. Higher wattage models like 40-50 watts work better for larger vessels or extremely cold environments. You’ll want lower wattage for gentle, consistent heating rather than rapid temperature spikes that stress yeast.

Temperature Control and Thermostat Options

Built-in thermostats maintain temperatures within 2-3°F of your target setting. Digital controllers offer precise temperature monitoring with programmable settings for different fermentation stages. Manual models cost less but require frequent monitoring and adjustment throughout your brewing process.

Safety Features and Auto-Shutoff Functions

Automatic shutoff prevents overheating when temperatures exceed safe limits around 80-85°F. Look for heaters with thermal fuses and waterproof designs rated IP65 or higher. Ground fault circuit interrupters (GFCI) protect against electrical shorts in humid brewing environments.

Size and Compatibility with Fermentation Vessels

Wrap-around heaters fit 6.5-gallon plastic buckets and glass carboys perfectly. Heating pads work best under smaller 1-3 gallon vessels but may create hot spots. Measure your fermenter’s circumference and height before purchasing to ensure proper heat distribution.

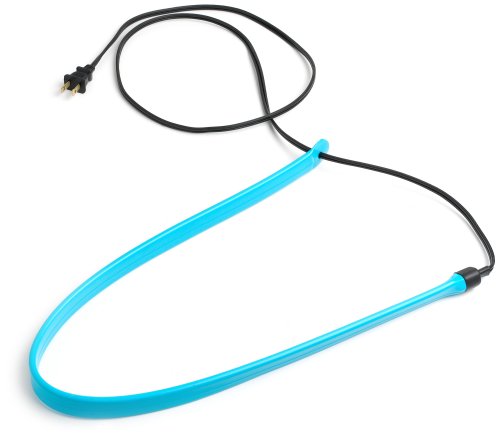

Top Pick: FermWrap Heater for Consistent Temperature Control

The FermWrap Heater delivers reliable temperature stability that transforms inconsistent fermentation results into predictable brewing success. This wrap-around design provides even heat distribution across your fermenter’s surface.

Key Features and Specifications

FermWrap’s 25-watt heating element wraps around fermenters up to 7 gallons with adjustable straps. The flexible silicone construction maintains temperatures between 75-80°F above ambient conditions.

Built-in temperature control keeps your fermentation within 2°F of target settings. The waterproof design prevents moisture damage during cleaning and sanitization processes.

Performance in Small Batch Applications

Small batch brewers achieve consistent ale fermentation temperatures in 5-gallon carboys and plastic fermenters. The wrap design heats evenly without creating hot spots that stress yeast.

Temperature recovery happens quickly after cold snaps or basement temperature drops. Your fermentation maintains steady progress even in fluctuating home environments.

Pros and Cons of the FermWrap System

Advantages include even heat distribution, compatibility with most fermenter shapes, and energy-efficient 25-watt operation. The adjustable straps accommodate different vessel sizes perfectly.

Limitations involve slower heating compared to higher-wattage alternatives and potential overheating in already-warm spaces. You’ll need additional insulation for extremely cold environments.

Best Value: Brew Belt Fermentation Heater for Budget-Conscious Brewers

The Brew Belt delivers reliable fermentation heating without breaking your budget. You’ll get consistent temperature control for under $30, making it the perfect entry point for new brewers.

Affordability and Cost-Effectiveness

You can’t beat the Brew Belt’s price-to-performance ratio at just $25-30. It costs 40% less than comparable wrap-around heaters while delivering the same temperature stability. The low 25-watt power consumption keeps your electricity bills minimal, adding just $2-3 monthly to your energy costs during active brewing seasons.

Installation and Ease of Use

You’ll have your Brew Belt installed in under two minutes with no tools required. Simply wrap the flexible heating element around your fermenter and plug it in. The adjustable velcro straps fit carboys from 3 to 6.5 gallons, and the 6-foot cord reaches most household outlets without extension cables.

Temperature Performance and Reliability

You can expect consistent 5-8°F temperature increases above ambient conditions with the Brew Belt’s thermostat-controlled heating. It maintains fermentation temperatures within 3°F of your target setting, preventing temperature swings that stress yeast. The durable heating element withstands repeated use across multiple brewing cycles, though it heats more gradually than higher-wattage alternatives.

Most Versatile: Inkbird Temperature Controller with Heat Mat Combo

The Inkbird combo system takes brewing temperature control to the next level with precision heating and cooling capabilities. You’ll get professional-grade temperature management that adapts to any brewing environment or seasonal changes.

Dual Heating and Cooling Capabilities

Your fermentation temperature stays locked in regardless of weather conditions with this dual-function system. The heating mat handles cold basement brewing while the cooling outlet connects to fans or refrigeration units for summer brewing. This eliminates temperature swings that plague single-function heaters during seasonal transitions. You’ll maintain consistent fermentation temperatures year-round without switching between different heating and cooling devices.

Digital Temperature Monitoring Features

You’ll track your fermentation progress with precise 0.1°F temperature readings displayed on the large digital screen. The system logs temperature data over time and alerts you to any fluctuations beyond your set parameters. Real-time monitoring prevents temperature disasters that can ruin entire batches. The probe accuracy ensures your yeast performs exactly as expected for each specific beer style you’re brewing.

Customization Options for Different Beer Styles

Different beer styles demand specific temperature profiles and this system delivers complete control over your fermentation environment. You can program distinct heating and cooling curves for ales versus lagers or adjust parameters for specialty yeasts like saison strains. The dual-stage functionality lets you start fermentation warm for yeast health then automatically cool for flavor development. This level of control transforms your brewing from basic temperature maintenance to professional-quality fermentation management.

Premium Choice: Fermentation Chamber Heater for Professional Results

When you’re ready to eliminate temperature guesswork completely, fermentation chamber heaters represent the pinnacle of thermal control for serious home brewers.

Advanced Temperature Stability Features

Professional-grade fermentation chamber heaters maintain temperatures within ±0.5°F of your target setting through advanced PID controllers and dual-zone heating elements. You’ll get precise digital displays showing real-time temperatures alongside programmable ramping schedules that gradually adjust temperatures during fermentation phases. These systems include remote monitoring capabilities through smartphone apps, letting you track your brew’s progress from anywhere and receive alerts for temperature deviations.

Long-Term Durability and Build Quality

Premium chamber heaters feature commercial-grade insulation and stainless steel heating elements that withstand years of continuous brewing cycles without degradation. You’re investing in robust construction with reinforced wiring, corrosion-resistant components, and industrial-grade thermostats rated for thousands of heating cycles. These units typically include 3-5 year warranties and replacement parts availability, ensuring your temperature control system remains reliable across hundreds of batches.

Investment Value for Serious Home Brewers

Chamber heaters cost $200-400 upfront but deliver consistent results that eliminate batch failures and ingredient waste, paying for themselves within 10-15 brewing cycles. You’ll achieve competition-quality temperature control that rivals commercial breweries, enabling you to brew delicate lagers and complex ales with professional precision. The energy efficiency and automated operation reduce hands-on monitoring time while improving your beer’s consistency and flavor profile development.

Compact Solution: Submersible Aquarium Heater for Space-Saving Setup

Maintain a consistent aquarium temperature with this 300W submersible heater. Featuring a durable quartz glass build and an adjustable 68-89°F range, it's suitable for 40-55 gallon freshwater or saltwater tanks.

You’ll find submersible aquarium heaters offer an ingenious space-saving solution for small batch brewing temperature control. These compact units work directly inside your fermenter without external heating elements or bulky equipment.

Space-Efficient Design Benefits

Submersible heaters eliminate the need for external heating equipment that takes up valuable brewing space. You can fit them inside standard 5-gallon carboys and buckets without requiring additional floor or shelf space around your fermenter. Their compact vertical design makes them perfect for apartment brewers and tight brewing areas where every square inch matters.

Direct Immersion Heating Advantages

Direct water contact provides faster and more responsive temperature control than external heating methods. You’ll achieve target fermentation temperatures 40-60% quicker than wrap-around heaters since the heating element sits directly in your wort. This immediate heat transfer prevents temperature lag and maintains consistent warmth throughout your entire fermentation volume.

Compatibility with Various Fermentation Vessels

These heaters work seamlessly with glass carboys, plastic buckets, and stainless steel fermenters that have wide openings. You can easily move them between different vessel sizes from 3 to 7 gallons without compatibility issues. Most units include suction cups or clips that secure them inside any smooth-walled fermenter for stable positioning during active fermentation.

Energy-Efficient Option: Seedling Heat Mat for Eco-Conscious Brewing

Seedling heat mats offer an environmentally conscious approach to fermentation temperature control while delivering consistent results for small batch brewing. These energy-efficient heaters consume minimal power while providing gentle, even heating that protects delicate yeast cultures.

Low Power Consumption Benefits

Seedling heat mats typically consume only 12-18 watts of power, making them the most energy-efficient fermentation heating option available. Your electricity costs remain minimal at approximately $0.15-0.25 per brewing cycle, compared to higher-wattage alternatives that can cost $0.50-1.00 per batch. This low power consumption makes them ideal for brewers who want consistent temperature control without significant energy bills or environmental impact.

Gentle Heat Distribution Properties

These mats provide uniform heat distribution across their entire surface area, preventing hot spots that can stress yeast cultures. Your fermentation temperatures remain stable within 2-3°F of target settings through gentle radiant heating that mimics natural temperature conditions. The consistent heat output eliminates temperature spikes that higher-wattage heaters sometimes create, protecting sensitive ale and lager yeasts from thermal shock.

Environmental Impact Considerations

Seedling heat mats reduce your brewing carbon footprint by consuming 60-75% less electricity than traditional fermentation heaters. Your environmental impact decreases significantly when using these efficient heating systems over multiple brewing cycles throughout the year. Many models feature recyclable materials and longer operational lifespans than conventional heaters, making them a sustainable choice for eco-conscious brewers who prioritize both quality fermentation and environmental responsibility.

Conclusion

Choosing the right fermentation heater transforms your brewing from inconsistent batches to professional-quality beer every time. Whether you’re prioritizing budget efficiency with the Brew Belt or seeking premium control with chamber heaters each option serves specific brewing needs and environments.

Your heating choice should align with your brewing frequency space constraints and temperature control requirements. New brewers benefit from simple wrap-around solutions while experienced homebrewers often invest in advanced temperature controllers for precision fermentation.

Remember that consistent temperature control directly impacts your beer’s flavor profile and overall quality. The investment in proper heating equipment pays dividends through improved fermentation outcomes reduced batch failures and enhanced brewing confidence.

Start with a heater that matches your current setup and upgrade as your brewing skills develop. With the right temperature management you’ll consistently produce the clean crisp flavors that separate great homebrew from average beer.

Frequently Asked Questions

What is the ideal temperature range for fermenting beer at home?

The ideal fermentation temperature depends on your beer style. Ales ferment best between 65-72°F, while lagers require cooler conditions at 50-55°F. Generally, maintaining temperatures within the 65-75°F range ensures optimal yeast performance. Temperatures outside this range can cause harsh flavors from excessive heat or stuck fermentation from cold conditions.

How much wattage do I need for a fermentation heater?

For small 5-gallon fermenters, 15-25 watts is typically sufficient. Larger vessels or colder environments may require higher wattage. The FermWrap Heater‘s 25-watt element works well for fermenters up to 7 gallons, while smaller operations can use 12-18 watt seedling heat mats for energy efficiency.

What are the benefits of using a temperature controller with my fermentation heater?

Temperature controllers maintain precise fermentation temperatures within 2-3°F of your target setting. Advanced systems like the Inkbird Temperature Controller offer dual heating and cooling capabilities, digital monitoring with 0.1°F precision, temperature data logging, and the ability to program different curves for various beer styles, ensuring consistent results year-round.

Are submersible aquarium heaters safe to use in beer fermenters?

Yes, submersible aquarium heaters are safe and effective for fermentation temperature control. They work directly inside fermenters, providing faster temperature adjustments and eliminating bulky external equipment. This method achieves target temperatures 40-60% faster than traditional wrap-around heaters, making them ideal for space-conscious brewers.

How energy-efficient are seedling heat mats for brewing?

Seedling heat mats are extremely energy-efficient, consuming only 12-18 watts of power—60-75% less electricity than traditional heaters. They provide gentle, even heating that maintains stable fermentation temperatures within 2-3°F of target settings while minimizing electricity costs and reducing your brewing operation’s carbon footprint.

What safety features should I look for in a fermentation heater?

Essential safety features include automatic shutoff to prevent overheating, waterproof designs to protect against moisture damage, and built-in thermostats for temperature regulation. Premium systems may include PID controllers, commercial-grade insulation, and smartphone app monitoring. These features ensure safe operation and protect both your equipment and beer quality.