6 Best Hoop House Anchors For Windy Locations Old Farmers Swear By

Secure your hoop house against high winds with these 6 time-tested anchors. Learn the methods old farmers trust to keep their structures firmly grounded.

There’s no worse feeling than hearing a 40-mile-per-hour gust rattle your hoop house in the middle of the night. You lay there wondering if the little steel stakes that came in the box are really up to the task. Investing in a hoop house is a serious step, and seeing it crumpled like a soda can is a costly, heartbreaking lesson in physics.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Standard Hoop House Anchors Often Fail

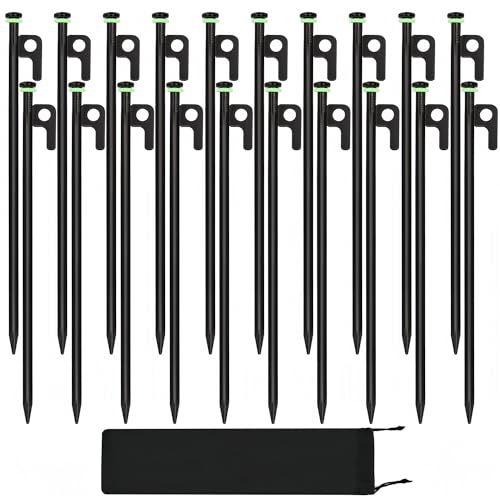

The anchors included in most hoop house kits are designed for ideal conditions, not the real world. They’re typically just straight metal stakes, maybe a foot long, meant to be hammered into the ground. They offer some resistance to a gentle breeze, but they are fundamentally flawed against serious wind.

Wind doesn’t just push sideways; it creates powerful uplift forces. As wind flows over the curved surface of a hoop house, it generates lift, much like an airplane wing. Those little stakes have almost no resistance to being pulled straight up, especially in soil that’s become soft from rain.

Think of it like trying to hold down a giant tent with a few flimsy pegs. A strong, sustained wind will work them loose, one by one. Once a single anchor fails, the load on the others increases exponentially, and a catastrophic failure is just moments away. Standard anchors protect against tipping, not flying.

Duckbill Earth Anchors for Unseen Strength

Duckbill anchors are a classic solution for a reason: they work like a toggle bolt in the soil. You drive a steel rod with the anchor attached into the ground. Once it’s deep enough, you pull back on the attached cable, which flips the "duckbill" horizontally, locking it firmly against the undisturbed earth.

The beauty of this system is its incredible holding power relative to its size. Because it’s locked against solid ground deep below the surface, its resistance to uplift is immense. You’re not just fighting the anchor; you’re fighting a huge cone of soil above it. They are also completely hidden once installed, which keeps your site looking clean and trip-free.

The main drawback is installation. You need a special drive rod, and getting them into rocky or heavily compacted clay soil can be a serious workout. If you hit a big rock, you have to pull it out and start over. But for most soil types, they provide a level of security that surface stakes can’t even approach.

Tie Down Engineering’s Penetrator Anchors

If you want serious holding power without digging or pounding, auger-style anchors are your answer. The "Penetrator" anchors from Tie Down Engineering are a popular example. These are essentially giant, sharpened steel corkscrews that you drive into the ground.

Their genius is in the installation. You can drive them with a heavy-duty impact wrench or a long pry bar, screwing them deep into the soil. The helical plates, or flukes, provide massive resistance to being pulled out. They come in various lengths and fluke diameters, allowing you to match the anchor to your soil type—longer anchors for sandy soil, wider flukes for loam.

This is a fantastic option for those who want a secure, semi-permanent solution that is also removable. Unlike concrete, you can unscrew them if you decide to move your hoop house. The main consideration is cost, as they are more expensive than simple rebar, but they are far cheaper than a new hoop house.

The Classic Rebar-Pinned Wooden Baseboard

A wooden baseboard is one of the most common and effective upgrades for any hoop house. You build a simple frame out of pressure-treated 2×6 or 2×8 lumber that matches the footprint of your structure. The hoop house ribs are then fastened directly to this wooden foundation.

But the wood itself isn’t the anchor. The real strength comes from pinning the baseboard to the ground with long pieces of rebar. You drill holes through the lumber and drive 2- to 4-foot lengths of rebar through the board and deep into the earth, preferably at opposing angles. This technique resists both lateral and uplift forces extremely well.

This method does more than just anchor the structure. It creates a solid, level base, makes it easier to attach wiggle wire channels for securing plastic, and helps seal out drafts and pests at ground level. The primary tradeoff is that the wood will eventually degrade, even if it’s pressure-treated, and rebar can still pull out of very loose or sandy soil during extreme weather.

Growers Solution Steel Ground Post System

For a truly integrated and robust foundation, steel ground posts are hard to beat. This system uses heavy-gauge galvanized steel posts that are driven deep into the ground at each rib location. The hoop house ribs then slide directly over or into these posts, creating a seamless and incredibly strong connection.

This approach effectively extends the hoop house frame several feet into the earth. It transfers wind loads directly into the subsoil, making the entire structure act as a single, unified unit. There’s no separate baseboard or anchor point that can become a weak link; the foundation is the frame.

The main hurdles are cost and installation. These systems are an investment, and you’ll need a manual or powered post driver to get them installed properly. Pounding a dozen or more steel posts 3 feet into the ground is not a task for the faint of heart. However, for a long-term structure in a high-wind area, the peace of mind is often worth the effort and expense.

DIY Concrete Piers for Permanent Stability

When you know your hoop house isn’t moving for a decade, concrete is the answer. Creating DIY concrete piers provides an absolutely immovable foundation. This involves digging holes below the frost line at key points along the frame, setting a form tube, and pouring concrete.

Before the concrete sets, you embed a galvanized J-bolt or a steel anchor bracket into the wet mix. This gives you a permanent, rock-solid point to bolt your baseboard or the hoop house ribs directly. A structure anchored this way isn’t going anywhere without an excavator.

This is, by far, the most labor-intensive and permanent solution. It requires planning, digging, mixing concrete, and precise placement. It’s not a good choice if you think you might want to relocate or expand your hoop house later. But if you’re building for the long haul in a location known for violent storms, nothing provides more security than a concrete footing.

Buried Deadman Anchors: The Ultimate DIY Hold

The "deadman" anchor is an old-timer’s trick that uses weight and leverage to create an incredibly effective, low-cost anchor. A deadman is simply a heavy, bulky object—like a salvaged railroad tie, a concrete block, or a small log—that you bury horizontally in a trench.

You attach a heavy-duty strap or galvanized cable to the center of the deadman before burying it, leaving the end accessible at the surface. This cable is then used to tie down the hoop house frame. The holding power is immense because the wind has to lift not only the anchor itself but also the massive weight of all the soil piled on top of it.

This is a fantastic DIY option that uses readily available materials. You can place them at the four corners or along the sides of your structure for maximum effect. The primary downside is the labor involved in digging the trenches, but the result is a hidden anchor with the holding power of a system that would otherwise cost hundreds of dollars.

Combining Anchors for a Fail-Safe System

The smartest approach in a truly windy location is redundancy. Don’t rely on a single type of anchor; use two different systems that work together to counter different forces. A professional engineer would call this creating a "fail-safe" system, and it’s a principle that serves the small farmer well.

A perfect example is combining a rebar-pinned baseboard with auger-style earth anchors.

- The baseboard and rebar excel at preventing the structure from sliding or shifting laterally.

- The auger anchors, connected to the frame with straps thrown over the top, provide superior resistance against vertical uplift.

When a major storm hits, the forces come from all directions. The wind pushes, lifts, and even creates suction. By using a combination of anchors, you ensure that no single point of failure can compromise the entire structure. One system might handle the shear forces while the other handles the uplift, keeping your investment safe and sound.

Ultimately, choosing the right anchor comes down to your soil, your budget, and how much risk you’re willing to take. Don’t let the anchor be an afterthought; it’s the most critical component for ensuring your hoop house survives to see another growing season. Over-engineer your anchoring system now, and you’ll sleep soundly through the storm later.