6 Wood Chipper Blade Sharpening Kits on a Homestead Budget

Boost your chipper’s performance and extend blade life. We review 6 affordable sharpening kits designed for the self-sufficient homesteader’s budget.

You’re feeding a branch into your wood chipper, and instead of a satisfying thwump-thwump-thwump of sharp blades biting into wood, you get a gut-wrenching groan from the engine. The machine shudders, the branch just gets mangled, and you’re left with a stringy, useless mess. That’s the sound of dull blades, and it’s a sound that costs you time, fuel, and frustration.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Sharp Chipper Blades Matter on the Homestead

Efficiency is everything when you have a hundred other tasks waiting. Sharp blades pull material in and process it cleanly, letting you work faster with less strain on your machine. Dull blades do the opposite; they smash and tear wood instead of cutting it, which means the engine has to work much harder to get the job done. This burns more gas and can lead to clogs and jams that stop you in your tracks.

The quality of your output depends entirely on the sharpness of your blades. A keen edge produces uniform, consistent chips that are perfect for mulching paths, adding to compost piles, or using as animal bedding. Dull blades create a stringy, fibrous pulp that mats down, decomposes poorly, and is generally difficult to work with. If you’re chipping for a purpose, you need a quality cut.

Most importantly, it’s a matter of machine health and safety. A struggling engine is an overheating engine, putting unnecessary wear on the clutch, belts, and bearings. Dull blades also increase the chance of the machine grabbing and violently kicking back a branch, which is a serious safety hazard. Keeping them sharp isn’t just about performance; it’s about preserving your investment and keeping yourself safe.

Work Sharp Ken Onion for Versatile Sharpening

The Work Sharp Ken Onion isn’t the cheapest tool on this list, but it might be the best value for a homesteader. It’s a compact, powered belt sharpener that can put a factory-sharp edge on almost anything, from your pocket knife to your mower blades and, yes, your chipper blades. Its value comes from its incredible versatility.

The system uses flexible abrasive belts and an adjustable angle guide (from 15 to 30 degrees). This combination makes it remarkably easy to get a consistent, convex edge that is both sharp and durable. You simply set the angle, select the right grit belt, and make a few smooth passes. For chipper blades, you can remove the guide and use the flat platen to create a perfect, flat bevel.

Think of this as an investment in a complete sharpening system for your homestead. While the upfront cost is higher than a simple stone, it replaces the need for multiple other tools. If you’re currently struggling to sharpen knives, axes, and other tools, the Ken Onion consolidates all those jobs into one effective and relatively foolproof machine.

WEN BG4270 Grinder for Power and Precision

A standard bench grinder is a workshop staple for a reason. Models like the WEN 6-inch grinder offer a lot of power for a very low price. For chipper blades that have seen better days—the ones with significant nicks and dings from hitting a rock or a piece of metal—a grinder can remove damaged material quickly and re-establish a new edge in minutes.

The process is straightforward but requires a careful hand. You use the tool rest to help stabilize the blade and present it to the spinning wheel at the correct angle. The key is to use very light pressure and keep the blade moving constantly across the face of the wheel. This prevents you from digging in and creating a hollow spot.

The biggest risk with a high-speed grinder is overheating the blade. If the edge turns blue, you’ve ruined the temper, making the steel soft and unable to hold an edge. To prevent this, have a bucket of water handy and dip the blade in it every few seconds to keep it cool. A bench grinder is fast and powerful, but it’s the least forgiving method on this list.

Lansky Deluxe 5-Stone System for Small Blades

Sometimes precision matters more than speed. The Lansky system is a guided-rod sharpener designed for knives, but it’s an excellent option for the smaller blades found in many electric chipper/shredders. It’s a manual system that prioritizes a perfect, repeatable angle over everything else.

The kit works by clamping the blade into a vise. You then select a sharpening stone, insert its guide rod into a pre-set angle slot, and make smooth strokes along the edge. Because the rod and slot control the angle, it’s virtually impossible to get it wrong. You progress through coarser to finer stones to create a razor-sharp edge.

This is not the tool for thick, heavy blades from a 6-inch gas-powered chipper. The clamp isn’t big enough, and the small stones would take forever. But for the small, flat blades on a 2-HP electric unit, the Lansky system provides a level of precision that’s hard to achieve freehand, ensuring both sides of your blade have a perfectly matched bevel.

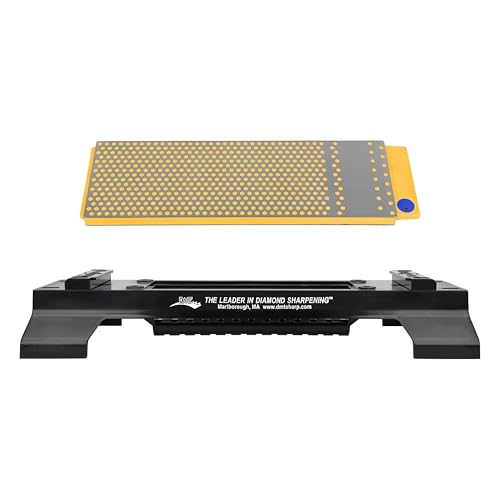

DMT DuoSharp Bench Stone for Manual Control

For those who prefer a more traditional, hands-on approach, a quality diamond stone is a fantastic choice. The DMT DuoSharp features a double-sided plate with a coarse grit for shaping and a fine grit for honing. Unlike water or oil stones, diamond plates cut fast, stay perfectly flat, and can be used dry, making for a clean and simple process.

This method gives you the most direct feedback. You can feel the stone biting into the steel and can easily check for the formation of a burr along the edge. The technique involves holding the blade at a consistent angle and sliding it across the stone as if you were trying to slice off a thin layer. It takes practice to master holding that angle steady, but the control it offers is unmatched.

While there’s a definite learning curve, the benefits are significant. There are no motors to maintain and no complex jigs to set up. A good diamond stone will last for years, making it a very frugal long-term investment. It’s a simple, reliable tool that connects you directly to the sharpening process.

Grizzly T32642 Wet Grinder for a Cooler Edge

A wet grinder is the perfect middle ground between the speed of a bench grinder and the safety of manual stones. These machines use a large, slow-turning grinding wheel that runs through a water bath. This design constantly cools the blade as you sharpen, completely eliminating the risk of overheating the steel and ruining its temper.

Models from companies like Grizzly or WEN offer the core function of the much more expensive Tormek systems at a price that’s accessible for a homestead budget. You set the angle using a tool rest and press the blade against the wet, spinning wheel. The slow speed and water lubrication create a beautifully fine, sharp edge without any of the drama or danger of a high-speed dry grinder.

The tradeoff is speed and mess. A wet grinder is slower than a dry grinder and, as the name implies, it involves water and grinding slurry. However, for someone who wants a powered solution but is worried about damaging their blades, a wet grinder is the safest and most reliable way to get a professional-quality edge.

The DIY Sandpaper Jig for Ultimate Frugality

You don’t need to spend a lot of money to get a sharp edge. For the ultimate budget-friendly solution, you can use sandpaper on a dead-flat surface—a method often called "scary sharp." All you need is a flat piece of glass, a granite tile, or even the cast-iron top of a table saw, along with some spray adhesive and wet/dry sandpaper in various grits.

The trick to making this work well is a simple jig. Take a block of wood and cut one end to match the bevel angle of your chipper blade (usually 30-35 degrees). By resting the blade on this angled block, you can slide the whole assembly back and forth across the sandpaper, ensuring a perfectly consistent angle with every stroke.

This is without a doubt the slowest method here. It takes patience and elbow grease. But the cost is minimal, and the results can be surprisingly good. If you only sharpen your blades once a season and can’t justify buying a dedicated tool, this DIY approach will get the job done effectively without denting your wallet.

Blade Reinstallation and Safety After Sharpening

Getting a sharp edge is only half the battle. Installing the blades correctly is just as important for the chipper’s performance and your safety. A poorly installed blade can cause dangerous vibrations, damage the machine, and will not cut effectively no matter how sharp it is.

Before reinstalling, thoroughly clean the blades and the rotor where they mount. Any leftover grit or grime can prevent the blade from seating properly. When you bolt them back on, follow these crucial steps:

- Check Blade Orientation: Make sure the sharp edge is facing the correct direction of rotation.

- Set the Anvil Gap: This is critical. The gap between the spinning blade and the stationary anvil (or counter-knife) determines the cutting action. Check your chipper’s manual for the proper specification—it’s often the thickness of a business card—and adjust it carefully.

- Torque the Bolts: Use a torque wrench to tighten the mounting bolts to the manufacturer’s specification. Overtightening can damage the bolts, while under-tightening can lead to a blade coming loose during operation.

Always put safety first. Disconnect the spark plug wire on a gas engine or unplug an electric model before you even think about touching the blades. Freshly sharpened blades are incredibly sharp, so wear thick leather or cut-resistant gloves during handling and installation. A moment of carelessness here can lead to a very serious injury.

Ultimately, the best sharpening kit is the one you’ll actually use. Whether it’s a versatile powered system or a simple sandpaper jig, the goal is the same: turning a frustrating chore back into a productive one. A sharp chipper is a happy chipper, and it makes managing homestead waste a whole lot easier.