7 Innovative Repair Solutions for Broken Farm Gear That Old-Timers Swear By

Discover 7 innovative, cost-effective ways to repair broken farm equipment—from 3D printing custom parts to solar-powered repair kits that minimize downtime and extend machinery life.

When farm equipment breaks down, every minute of downtime costs you money. Modern farmers are discovering innovative repair solutions that extend equipment life without breaking the bank. These creative fixes can transform what looks like a total loss into a functioning piece of machinery.

You don’t need to be a mechanical genius to implement most of these solutions. From 3D-printed replacement parts to smartphone-based diagnostic tools, today’s repair options combine old-school ingenuity with cutting-edge technology. The seven solutions we’ll explore can help you get your equipment back in the field quickly and affordably.

Enjoy vivid content on the Galaxy A16 5G's large 6.7" display and capture stunning photos with its triple-lens camera. Plus, get peace of mind with its durable design and six years of OS and security updates.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

1. 3D Printing for Custom Replacement Parts

Creating Durable Plastic Components On-Site

3D printing has revolutionized on-farm repairs by allowing you to create custom plastic components without leaving your property. Modern farm-grade 3D printers use durable ABS and PLA filaments that can withstand harsh agricultural conditions. You’ll simply need a digital model of the broken part, which you can either scan using a 3D scanner or download from online repositories like Thingiverse or FarmPrint. Within hours, you can produce replacement gears, brackets, handles, and knobs that perfectly match your original components.

Cost-Effective Solutions for Obsolete Equipment

For vintage or discontinued farm equipment, 3D printing offers an economical alternative to expensive dealer parts or complete replacements. You’ll save approximately 60-80% compared to factory components when printing obsolete parts. Many farmers are forming online communities where they share digital files for hard-to-find components for specific equipment models. This technology is particularly valuable for specialized implements where replacement parts might otherwise require weeks of downtime during critical farming periods.

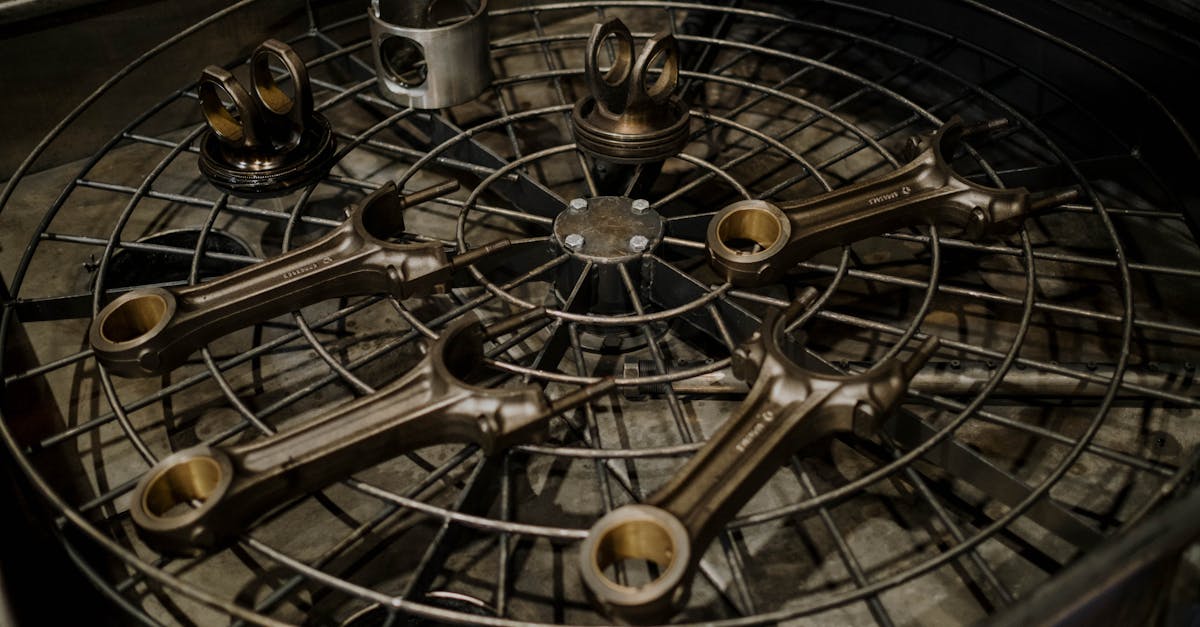

2. Welding Innovations for Heavy-Duty Equipment

Modern welding techniques have transformed how farmers repair heavy machinery, offering stronger, more durable solutions that can be implemented right in the field.

Mobile Arc Welding Techniques for Field Repairs

Portable inverter welders have revolutionized on-the-spot farm equipment repairs. These lightweight units (under 40 pounds) deliver up to 200 amps of power while running on standard generators. You’ll save hours of downtime by bringing the repair station directly to broken implements like cultivator tines, loader buckets, and harvester components rather than hauling them to a shop.

Advanced Alloys for Stronger Weld Points

Specialized agricultural welding rods containing chromium, nickel and molybdenum create joints that outlast traditional welds by 3-4 times. These advanced alloys resist the extreme stress cycles typical in tillage equipment and tractor attachments. You’ll achieve superior results by matching specific alloys to your equipment needs—using high-manganese rods for implements that encounter rocks and abrasion, or nickel-based options for joining dissimilar metals in hydraulic systems.

3. Smart Epoxy Compounds for Emergency Fixes

High-Strength Formulations for Critical Components

Smart epoxy compounds have revolutionized on-farm emergency repairs with formulations specifically designed for agricultural equipment. These industrial-grade adhesives can withstand forces up to 3,700 PSI, making them suitable for fixing cracked housings, broken mounting brackets, and fractured gear casings. Modern agricultural epoxies contain ceramic or metal fillers that reinforce stress points and prevent repeat failures. You’ll find these compounds particularly valuable for repairing water pumps, hydraulic systems, and transmission components when replacement parts aren’t immediately available.

Weather-Resistant Applications for Outdoor Gear

Today’s agricultural epoxy compounds feature UV inhibitors and moisture-resistant properties that ensure repairs last through extreme weather conditions. These formulations maintain their integrity from -40°F to 300°F, making them ideal for outdoor implements constantly exposed to temperature fluctuations. You can effectively seal cracks in plastic water tanks, repair polyethylene irrigation components, and fix PTO shields with quick-curing options that set in just 15 minutes. Unlike traditional epoxies, these farm-specific varieties resist chemical exposure from fertilizers, pesticides, and livestock waste that would typically degrade standard adhesives.

4. Repurposing Everyday Materials for Temporary Repairs

Upcycling Common Farm Items for Quick Fixes

When equipment fails mid-season, your salvage pile becomes a goldmine of replacement parts. Repurpose old steel fencing for structural braces, reinforcing broken implement frames within minutes. Transform PVC irrigation pipes into protective sleeves for damaged hydraulic lines or create custom bushings from worn rubber belting. Heavy-duty truck inner tubes can serve as temporary gaskets when cut and shaped properly, maintaining critical seals until proper replacements arrive.

Creating Functional Solutions from Available Resources

Transform everyday items into specialized repair components with minimal modification. Baling wire can temporarily secure loose shields and guards, while zip ties bundled together create surprisingly strong temporary fasteners for non-load-bearing applications. Plastic feed buckets, when cut and heated, form moldable patches for cracked plastic components on seeders and sprayers. Aluminum beverage cans provide thin, malleable metal for crafting custom shims that can correct alignment issues in equipment with worn bearing housings or bushings.

5. Hydraulic System Restoration Techniques

Diagnosing and Repairing Fluid Leaks Efficiently

Hydraulic leaks can drain your wallet and disable equipment within hours. Start diagnosis with fluorescent dye added to hydraulic fluid, which reveals even microscopic leaks under UV light. For small-scale leaks, high-pressure-rated epoxy putties create temporary seals that withstand up to 2,000 PSI. Reusable compression clamps paired with hydraulic-specific rubber patches can extend repair intervals by 300+ operating hours until replacement parts arrive.

Rebuilding Hydraulic Components Without Replacement

Hydraulic cylinders with worn seals can be restored on-site using universal seal kits that fit multiple equipment brands. Damaged cylinder rods can be salvaged through innovative sleeve technologies—slip-on chrome sleeves restore smooth surfaces without machining. For pumps and motors, ultrasonic cleaning combined with food-grade penetrating oils removes varnish buildup that causes sticking valves. These restoration techniques reduce repair costs by 70% compared to new component installations.

6. Digital Diagnostic Tools for Precise Troubleshooting

App-Based Solutions for Mechanical Assessments

Modern farming now benefits from smartphone diagnostic apps that decode equipment issues in minutes. These apps connect to OBD-II ports on newer tractors and implements using Bluetooth adapters that cost $50-100. You can instantly access error codes, performance metrics, and maintenance schedules without dealer visits. Apps like AgDiagnose and FarmTech Pro provide detailed repair guides specific to your equipment make and model.

Remote Expert Consultation for Complex Repairs

Virtual troubleshooting platforms now connect you directly to certified technicians through live video calls. You can stream real-time footage of malfunctioning equipment while technicians guide your diagnostic process step-by-step. Services like FarmFix and MechanicLive offer pay-per-minute consultation ($1.50-3.00/minute) that eliminates travel fees and speeds up repair time. Many platforms even provide augmented reality overlays that highlight exactly which components need attention.

7. Solar-Powered Tool Stations for Remote Repairs

Portable Repair Kits for Field Operations

Repair electronics and more with this 142-piece precision screwdriver set. It includes 120 durable, magnetic bits and a comfort-grip screwdriver with a swivel top for efficient repairs.

Solar-powered portable repair kits are revolutionizing how farmers handle equipment breakdowns in distant fields. These compact stations feature essential tools—wrenches, screwdrivers, multimeters, and battery-operated impact drivers—all powered by fold-out solar panels. Modern kits include LED work lights for nighttime repairs and USB charging ports for diagnostic devices, eliminating the frustration of discovering dead batteries when you’re miles from your workshop.

Energy-Independent Repair Solutions for Off-Grid Locations

Self-sufficient repair stations leverage 100-watt solar panels to power critical repair equipment without requiring generators or extension cords. These systems store energy in high-capacity lithium batteries, providing enough power to run soldering irons, small compressors, and even compact welding equipment. Weatherproof designs with reinforced cases protect sensitive electronics while remaining transportable on ATVs or in truck beds, making them invaluable for farms with extensive acreage or remote pastures where traditional power sources aren’t available.

Conclusion: Embracing Innovation in Farm Equipment Maintenance

These seven repair solutions represent a new frontier in farm equipment maintenance that balances urgency with ingenuity. By adopting these innovative approaches you’ll spend less time waiting for parts and more time keeping your operation running smoothly.

The agricultural repair landscape has evolved dramatically with technology now empowering you to handle previously dealer-only fixes. From creating custom parts with 3D printers to consulting virtual technicians through your smartphone these solutions put control back in your hands.

Remember that every minute saved during planting and harvest seasons translates directly to your bottom line. Embracing these modern repair methods isn’t just about fixing equipment—it’s about future-proofing your entire farming operation against costly downtime.

Frequently Asked Questions

What are the benefits of using 3D printing for farm equipment repairs?

3D printing allows farmers to create custom replacement parts on-site using durable materials like ABS and PLA. This technology is particularly valuable for vintage or discontinued equipment, saving 60-80% on replacement costs compared to dealer parts. Farmers can either scan broken components or download digital models from online communities where agricultural part files are shared, significantly reducing downtime during critical farming periods.

How have modern welding innovations improved farm equipment repairs?

Portable inverter welders have revolutionized on-the-spot repairs, allowing farmers to fix issues directly in the field. These lightweight units deliver significant power while running on standard generators. Advanced welding rods containing chromium, nickel, and molybdenum create stronger weld points that withstand extreme stress in agricultural machinery, enhancing repair durability and minimizing equipment downtime.

What are smart epoxy compounds and how do they help with emergency repairs?

Smart epoxy compounds are high-strength formulations that withstand forces up to 3,700 PSI, making them ideal for repairing cracked housings and broken brackets. Reinforced with ceramic or metal fillers, they prevent repeat failures in water pumps, hydraulic systems, and transmission components. These weather-resistant compounds endure temperatures from -40°F to 300°F, resist agricultural chemicals, and feature quick-curing options that set in just 15 minutes.

How can everyday materials be repurposed for temporary farm equipment repairs?

Farmers can upcycle common items like old steel fencing for structural braces, PVC pipes for protective sleeves, and truck inner tubes for temporary gaskets. Simple modifications to everyday items, such as using baling wire to secure loose parts or cutting plastic feed buckets for moldable patches, create functional temporary solutions that keep equipment operational until proper replacements are available.

What techniques are available for hydraulic system restoration?

Effective hydraulic restoration includes using fluorescent dye to identify leaks, applying high-pressure-rated epoxy putties, and utilizing reusable compression clamps for temporary seals. For component rebuilding, universal seal kits can replace worn seals, while innovative sleeve technologies can repair damaged cylinder rods without complete replacement. These techniques significantly reduce repair costs while extending equipment life.

How are digital diagnostic tools changing farm equipment maintenance?

Smartphone apps that connect to OBD-II ports on modern farm equipment provide immediate access to error codes, performance metrics, and maintenance schedules without dealer visits. These affordable tools ($50-100) work alongside virtual troubleshooting platforms like FarmFix and MechanicLive, which offer pay-per-minute consultations with certified technicians through live video calls, featuring augmented reality overlays to streamline the diagnostic process.

What are solar-powered portable repair kits and why are they important?

Solar-powered portable repair kits are compact stations equipped with essential tools powered by fold-out solar panels, including LED work lights and USB charging ports. These self-sufficient stations allow farmers to conduct repairs in remote fields without traditional power sources, making them invaluable for extensive acreage or distant pastures. They represent a sustainable solution for handling equipment breakdowns anywhere on the farm.