4 Best Boom Sprayer Nozzles for Row Crops That Prevent Drift

Discover the top 4 boom sprayer nozzles for row crops that maximize chemical efficiency, reduce drift, and boost yields through superior droplet control and coverage.

The bottom line: Your boom sprayer’s effectiveness depends entirely on choosing the right nozzles for your specific row crops and field conditions.

Why it matters: The wrong nozzle can waste expensive chemicals reduce coverage and hurt your yields while the right one maximizes spray efficiency and protects your investment.

What’s ahead: We’ll break down the four top-performing nozzle types that deliver consistent results across corn soybeans and other row crops so you can make the best choice for your operation.

|

$48.36

|

$75.97

|

$126.88

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Boom Sprayer Nozzles for Row Crop Applications

You’ll find boom sprayer nozzles are the heart of your application system, controlling droplet size, spray pattern, and chemical distribution across your crop rows. Getting this fundamental piece right determines whether your spray investment pays off or gets wasted.

Key Performance Factors to Consider

Droplet size consistency drives your application success more than any other factor. You need nozzles that produce uniform droplets for even coverage without excessive drift.

Flow rate accuracy ensures you’re applying the correct chemical volume per acre. Worn or mismatched nozzles create application gaps and overlaps.

Operating pressure range affects your spray quality and equipment longevity. Choose nozzles that perform optimally within your sprayer’s pressure capabilities.

How Nozzle Selection Impacts Crop Yield and Protection

Wrong nozzles create uneven chemical distribution that leaves crop rows under-protected or over-treated. You’ll see reduced pest control effectiveness and potential crop injury from concentrated droplets.

Proper nozzle matching delivers consistent coverage across your spray boom width, maximizing chemical efficacy. This translates to better weed control, disease prevention, and ultimately higher yields.

Drift reduction nozzles protect neighboring crops and sensitive areas while maintaining on-target deposition rates for your intended application zone.

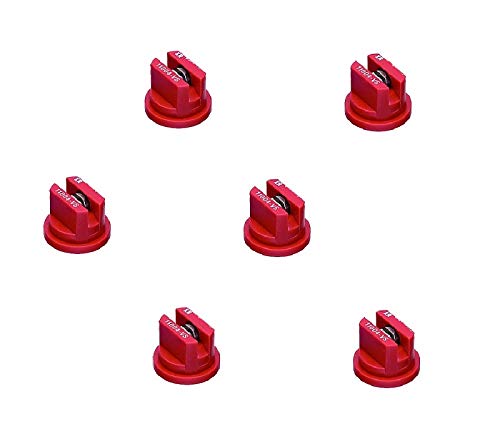

TeeJet XR11004 Extended Range Flat Fan Nozzle

The XR11004 stands out as a versatile workhorse that performs consistently across different spray applications and weather conditions. You’ll appreciate its reliability when treating your corn and soybean fields throughout the growing season.

Superior Drift Reduction Technology

You’ll get significantly less drift with the XR11004’s pre-orifice design that creates larger, more uniform droplets. This technology reduces chemical loss by up to 50% compared to standard flat fan nozzles, keeping your herbicides and fungicides where they belong. The controlled droplet formation means you can spray during slightly windier conditions without compromising application quality.

Optimal Spray Pattern for Uniform Coverage

The XR11004 delivers a 110-degree spray angle that provides excellent overlap between nozzles at standard boom heights. You’ll see consistent coverage across your spray swath with minimal streaking or gaps that can lead to breakthrough weeds. The extended range design maintains pattern integrity from 15 to 60 PSI, giving you flexibility to adjust pressure based on field conditions.

Pressure Range and Flow Rate Specifications

This nozzle operates efficiently between 15-60 PSI with a flow rate of 0.4 gallons per minute at 40 PSI. You can run lower pressures for drift-sensitive applications or increase pressure for better canopy penetration without losing spray quality. The wide operating range means you won’t need multiple nozzle sets for different chemical applications throughout your season.

Hypro Guardian Air Ultra Low Drift Nozzle

The Hypro Guardian Air stands out as a premium choice for row crop applications where drift control is absolutely critical. You’ll find this nozzle particularly valuable when spraying near sensitive areas or during challenging weather windows.

Advanced Air Induction Design

Air induction technology draws ambient air into the spray stream through venturi chambers, creating larger droplet sizes that resist wind drift. This design produces a distinctive hollow cone pattern that maintains coverage while reducing fine droplet formation by up to 75%. You’ll notice improved chemical retention on target crops with significantly less product lost to atmospheric drift.

Enhanced Droplet Size Control

The Guardian Air produces consistent medium to coarse droplets ranging from 300-600 microns, giving you predictable spray characteristics across varying pressure ranges. You can operate between 20-80 PSI while maintaining optimal droplet size distribution for herbicide applications. This consistency translates to more uniform chemical coverage and better weed control results in your corn and soybean fields.

Field Performance in Various Weather Conditions

Weather flexibility becomes a major advantage with the Guardian Air’s drift-resistant droplet profile. You can spray confidently in 10-15 mph winds that would ground operations with conventional nozzles, extending your application windows significantly. The air-induced droplets maintain their integrity longer in flight, delivering consistent performance even during temperature inversions or high humidity conditions.

TeeJet AIXR11004 Air Induction Extended Range Nozzle

The TeeJet AIXR11004 stands out as a premium air induction nozzle designed specifically for challenging spray conditions in row crop applications. This nozzle combines advanced air induction technology with proven flat fan spray patterns to deliver exceptional drift control and coverage consistency.

Patented Pre-Orifice Technology

The AIXR11004’s pre-orifice design creates a unique two-stage mixing process that draws ambient air into the liquid stream before droplet formation. This patented technology produces larger, air-filled droplets that resist wind drift while maintaining excellent spray penetration and coverage. The air-induced droplets reduce drift potential by up to 90% compared to conventional flat fan nozzles.

Consistent Performance Across Pressure Ranges

This nozzle maintains reliable droplet size and spray quality across operating pressures from 20-80 PSI, providing flexibility for varying field conditions and application requirements. At 40 PSI, it delivers 0.4 gallons per minute with medium droplet classification, ensuring predictable performance throughout your spray operation. The extended pressure range allows you to adjust application rates without compromising spray quality or coverage uniformity.

Compatibility with Different Chemical Applications

The AIXR11004 works effectively with herbicides, fungicides, and insecticides across various viscosities and formulations including oil-based adjuvants and suspension concentrates. Its ceramic construction resists chemical wear and maintains precise orifice dimensions even with abrasive formulations like wettable powders. The nozzle’s versatile spray characteristics accommodate both contact and systemic chemicals while maintaining optimal droplet penetration for maximum efficacy.

Lechler ID3-11004 Air Induction Nozzle

The Lechler ID3-11004 represents the pinnacle of air induction technology for row crop applications. This German-engineered nozzle delivers exceptional drift control while maintaining precise chemical distribution across your fields.

German Engineering for Precision Agriculture

Lechler’s ID3-11004 features advanced Venturi air induction technology that creates consistent air-filled droplets. The precision-machined orifice produces uniform droplet sizes ranging from 400-700 microns across operating pressures of 15-60 PSI. You’ll achieve predictable spray patterns with excellent chemical distribution, ensuring maximum efficacy for herbicides, fungicides, and insecticides in your row crop operations.

Exceptional Drift Control Features

This nozzle reduces drift potential by up to 85% compared to standard flat fan designs through its dual-chamber air induction system. The larger, air-filled droplets resist wind displacement while maintaining penetration into crop canopies. You can confidently spray in winds up to 12 mph, significantly extending your application windows during critical timing periods for weed and pest control.

Long-Term Durability and Wear Resistance

Lechler constructs the ID3-11004 with hardened ceramic components that resist chemical corrosion and abrasive wear. The reinforced air induction chamber withstands repeated pressure cycles without degrading spray quality. You’ll maintain consistent flow rates and droplet characteristics for multiple seasons, making this nozzle a cost-effective investment for operations requiring reliable, long-term performance.

Conclusion

Selecting the right boom sprayer nozzle transforms your row crop operations from guesswork into precision agriculture. Each nozzle discussed offers distinct advantages that directly impact your bottom line through improved coverage and reduced waste.

Your choice ultimately depends on your specific field conditions and spray requirements. Consider factors like typical wind conditions drift sensitivity and chemical compatibility when making your decision.

Don’t overlook the long-term value of investing in quality nozzles. While premium options may cost more upfront they’ll deliver consistent performance season after season while protecting your crop investment.

Start by evaluating your current spray challenges then match them with the nozzle features that address those specific needs. Your crops and your wallet will thank you for the upgrade.

Frequently Asked Questions

Why is choosing the right nozzle important for boom sprayers in row crops?

Selecting the appropriate nozzle is crucial because it directly impacts spray effectiveness, chemical usage, and crop yields. The wrong nozzle can lead to wasted chemicals, poor coverage, and reduced protection against pests and diseases. Proper nozzles ensure uniform droplet distribution, minimize drift, and maximize the efficacy of your chemical applications, ultimately protecting your investment and improving crop performance.

What are the key performance factors to consider when selecting boom sprayer nozzles?

The three main performance factors are droplet size consistency, flow rate accuracy, and operating pressure range. Uniform droplet size ensures even coverage and reduces drift. Accurate flow rates prevent application gaps and overlaps that can harm crops. The proper operating pressure range maintains consistent performance across different field conditions and spray requirements.

How does incorrect nozzle selection affect crop yield and protection?

Incorrect nozzles lead to uneven chemical distribution, creating areas with inadequate pest control and potential crop injury from over-application. This results in reduced weed control effectiveness, poor disease prevention, and ultimately lower yields. Inconsistent coverage also wastes expensive chemicals and reduces the return on investment for crop protection products.

What makes the TeeJet XR11004 Extended Range Flat Fan Nozzle effective?

The XR11004 features superior drift reduction technology with a pre-orifice design that creates larger, uniform droplets. It reduces chemical loss by up to 50% compared to standard nozzles and provides a 110-degree spray angle for excellent overlap. Operating efficiently between 15-60 PSI, it’s particularly effective for corn and soybean applications in various weather conditions.

How does the Hypro Guardian Air Ultra Low Drift Nozzle control drift?

The Guardian Air uses advanced air induction technology to create larger droplets that resist wind drift. It reduces fine droplet formation by up to 75% and produces consistent medium to coarse droplets ranging from 300-600 microns. This design allows confident spraying in winds of 10-15 mph while maintaining predictable spray characteristics across 20-80 PSI.

What are the benefits of air induction nozzles like the TeeJet AIXR11004?

Air induction nozzles like the AIXR11004 reduce drift potential by up to 90% compared to conventional nozzles through patented pre-orifice technology. They maintain reliable droplet size across wide pressure ranges (20-80 PSI) and are compatible with various chemical applications. The ceramic construction provides excellent chemical resistance and longer service life.

How does the Lechler ID3-11004 improve spray performance?

The ID3-11004 uses advanced Venturi air induction technology to create consistent air-filled droplets, reducing drift potential by up to 85%. It allows confident spraying in winds up to 12 mph while maintaining reliable chemical distribution. The hardened ceramic construction ensures durability and long-term performance in demanding field conditions.