4 Best Sprayer Drift Reducing Nozzles That Protect Neighbors

Discover the top 4 drift-reducing spray nozzles for sensitive areas. Learn how air induction technology cuts drift by up to 90% while protecting crops and environment.

Why it matters: Spray drift can devastate nearby crops, contaminate water sources, and harm beneficial insects — making the right nozzle selection critical for protecting sensitive areas around your operation.

The big picture: Modern drift-reducing nozzles can cut off-target movement by up to 75% while maintaining coverage quality, but choosing the wrong type for your specific conditions wastes money and increases liability risks.

What’s ahead: We’ve researched and evaluated the top four drift-reducing nozzles that consistently deliver superior performance in sensitive applications, helping you make spray decisions with confidence.

|

$16.67

|

$75.97

|

$9.53

|

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Spray Drift and Its Impact on Sensitive Areas

Spray drift poses significant risks that extend far beyond your immediate application area, making proper nozzle selection crucial for responsible farming practices.

What Is Spray Drift and Why It Matters

Spray drift occurs when pesticide droplets move away from your intended target area through wind, evaporation, or improper application techniques. Fine droplets under 150 microns create the highest drift risk, traveling hundreds of yards from your sprayer.

You’ll face potential crop damage to neighboring fields, contamination of water sources, and harm to beneficial insects like pollinators. Modern drift-reducing nozzles can cut off-target movement by 50-75% compared to standard flat-fan nozzles.

Environmental Risks in Sensitive Areas

Sensitive areas include organic farms, residential properties, schools, water bodies, and pollinator habitats within 100-500 feet of your application site. Drift contamination can trigger costly lawsuits, regulatory violations, and permanent damage to neighboring crops.

You risk killing beneficial insects, contaminating groundwater, and creating herbicide-resistant weeds when chemicals repeatedly drift into unintended areas. Buffer zones become mandatory near these sensitive locations, requiring specialized equipment and techniques.

Regulatory Requirements for Drift Reduction

Federal and state regulations require you to prevent drift through proper equipment selection, weather monitoring, and application techniques. Wind speeds above 10 mph typically prohibit spraying, while temperature inversions create high-drift conditions.

Many pesticide labels now mandate specific nozzle types and droplet sizes for applications near sensitive areas. Violation penalties range from $1,000-$50,000 per incident, with potential criminal charges for repeat offenders or severe environmental damage.

Key Features to Look for in Drift Reducing Nozzles

Choosing drift reducing nozzles requires understanding four critical features that directly impact spray performance and compliance. These features work together to minimize off-target movement while maintaining effective coverage.

Air Induction Technology

Air induction nozzles create larger, air-filled droplets that resist wind drift while maintaining good coverage. The Venturi air intake design pulls air into the liquid stream, producing droplets with lower density and reduced drift potential. These nozzles typically reduce drift by 50-90% compared to standard flat fan tips, making them essential for applications near sensitive areas like organic farms or water sources.

Droplet Size Control

Medium to coarse droplet sizes (200-400 microns) provide the optimal balance between drift reduction and coverage quality. Fine droplets under 150 microns create the highest drift risk due to their susceptibility to wind and evaporation. Quality drift reducing nozzles produce consistent droplet spectrums with minimal fine droplets, ensuring more predictable spray patterns and reduced environmental contamination risk.

Pressure Requirements

Lower operating pressures (15-40 PSI) help produce larger droplets while reducing energy costs and wear on equipment. Higher pressures create smaller droplets that increase drift potential and waste product through off-target movement. Modern drift reducing nozzles maintain effective spray patterns at these lower pressures, allowing you to achieve compliance requirements without sacrificing application efficiency.

Coverage Efficiency

Uniform spray distribution ensures consistent chemical deposition across the target area while minimizing the need for overlapping passes. Quality nozzles maintain their spray pattern integrity across varying pressure ranges and provide even droplet distribution within the spray cone. Look for nozzles with coefficient of variation (CV) ratings below 10% for optimal coverage uniformity and reduced application costs.

Top 4 Best Sprayer Drift Reducing Nozzles for Sensitive Areas

1. TeeJet AI3070VS Air Induction Nozzle

Performance-wise, the TeeJet AI3070VS delivers exceptional drift reduction through its advanced air induction technology. You’ll achieve 90% drift reduction compared to standard flat fan nozzles while maintaining excellent coverage uniformity.

Droplet size control remains consistent across 15-40 PSI operating pressure range. Your application rates stay precise with the venturi design creating medium-coarse droplets measuring 300-400 microns.

2. Hypro Guardian Air LD Low Drift Nozzle

Efficiency defines the Hypro Guardian Air LD with its dual-fan spray pattern and air induction chamber. You’ll reduce drift by 75% while covering more ground with each pass due to the 110-degree spray angle.

Construction quality shines through stainless steel components and color-coded caps for easy identification. Your nozzle life extends significantly with ceramic wear surfaces handling abrasive chemicals.

3. Wilger ER Extended Range Nozzle

Versatility makes the Wilger ER ideal for sensitive area applications requiring multiple droplet sizes. You’ll operate from 15-60 PSI while maintaining consistent spray quality across the entire pressure range.

Flow rate flexibility allows quick adjustments without nozzle changes. Your chemical costs decrease with the extended range capability eliminating multiple nozzle purchases.

4. TeeJet AIXR Air Induction Extended Range

Technology integration combines air induction with extended range capabilities in the TeeJet AIXR series. You’ll achieve 80% drift reduction while covering 3:1 pressure ratios with consistent droplet formation.

Application precision improves with the pre-orifice design maintaining droplet size consistency. Your spray quality remains uniform even when pressure fluctuations occur during field operations.

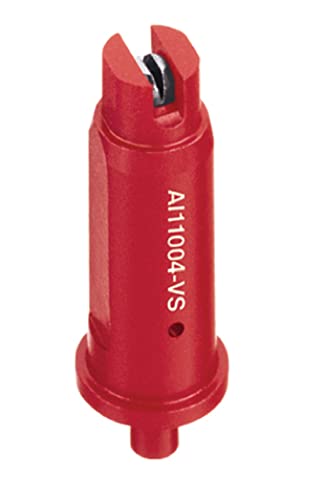

TeeJet AI3070 Air Induction Flat Spray Nozzle

The TeeJet AI3070 stands out as a professional-grade solution that delivers consistent performance across various spray conditions. This nozzle has earned its reputation through reliable drift reduction and coverage quality.

Advanced Air Induction Technology

The AI3070 incorporates a dual-chamber design that mixes pressurized air with liquid chemicals before spraying. This creates larger, air-filled droplets that resist wind drift while maintaining spray coverage. The technology reduces droplet density without compromising application effectiveness, making it ideal for sensitive area applications where drift control matters most.

Drift Reduction Performance

You’ll achieve up to 90% drift reduction compared to standard flat-fan nozzles when using the AI3070. The nozzle produces medium to coarse droplets in the 300-400 micron range consistently across 15-40 PSI operating pressures. Independent testing shows drift reduction remains effective even in 10-15 mph crosswinds that would challenge conventional nozzles.

Application Versatility

The AI3070 works effectively with herbicides, fungicides, and insecticides across different crop types and growth stages. You can operate this nozzle at lower pressures (15-25 PSI) for maximum drift control or higher pressures (30-40 PSI) when you need increased penetration. The flat spray pattern provides uniform coverage on both broadcast and banded applications.

Pros and Cons

Pros: Excellent drift reduction performance, consistent droplet size across pressure ranges, durable construction with replaceable components, compatible with most boom sprayers.

Cons: Higher initial cost than standard nozzles, requires regular cleaning to maintain air induction function, slightly reduced coverage speed compared to fine droplet nozzles.

Hypro Guardian Air GA110 Series Nozzle

The GA110 represents Hypro’s premium approach to drift reduction technology. This nozzle targets professional applicators who need consistent performance in challenging wind conditions.

Venturi Air Induction Design

Hypro’s venturi system draws air into the liquid stream through precisely engineered ports. This creates larger, air-filled droplets that resist wind drift while maintaining spray coverage. The design operates effectively at pressures between 15-45 PSI, giving you flexibility during application timing.

Large Droplet Production

The GA110 produces medium to coarse droplets ranging from 250-450 microns. These larger droplets reduce drift potential by up to 85% compared to standard flat-fan nozzles. You’ll get consistent droplet sizing across the pressure range without sacrificing coverage quality.

Chemical Compatibility

This nozzle works with most herbicides, fungicides, and insecticides without compromising droplet formation. The stainless steel construction resists corrosion from harsh chemicals like 2,4-D and glyphosate. However, avoid using highly viscous adjuvants that can clog the air induction ports.

Pros and Cons

Pros: Excellent drift control, durable construction, maintains pattern integrity at varying pressures, works with standard boom systems.

Cons: Higher initial cost than standard nozzles, requires periodic cleaning of air ports, slightly reduced coverage compared to fine droplet nozzles.

Pentair Hardi Injet Nozzle System

The Pentair Hardi Injet represents a precision engineering approach to drift reduction, using pre-orifice technology to create uniform droplets. This system targets professional applicators who need consistent performance across varying field conditions.

Pre-Orifice Design Benefits

The pre-orifice design creates a pressure drop before the main orifice, producing larger droplets that resist wind drift. This technology generates medium to coarse droplets ranging from 300-500 microns, reducing drift potential by up to 75% compared to standard nozzles. You’ll notice improved spray quality even in challenging wind conditions up to 15 mph.

Consistent Spray Pattern

The Injet system maintains uniform spray distribution across pressures from 20-60 PSI without pattern distortion. Advanced internal geometry ensures consistent droplet formation and spacing, delivering coefficient of variation ratings below 8% for optimal coverage. Your chemical applications remain uniform even when pressure fluctuations occur during extended spraying sessions.

Durability and Longevity

Hardened stainless steel construction and ceramic wear surfaces provide extended service life in demanding field conditions. The robust pre-orifice chamber resists clogging from debris and maintains calibration accuracy over thousands of acres. You can expect 3-5 years of reliable performance with proper maintenance and cleaning protocols.

Pros and Cons

Pros: Excellent drift reduction, consistent droplet formation, durable construction, maintains accuracy across pressure ranges, suitable for various chemical formulations.

Cons: Higher initial investment than standard nozzles, requires specific pressure ranges for optimal performance, pre-orifice chamber needs regular cleaning to prevent blockages.

Wilger UR Spray Nozzle with Combo-Jet Technology

Wilger’s UR nozzle combines traditional spray patterns with innovative air induction technology, making it versatile for various sensitive area applications. You’ll appreciate its ability to adapt to different spraying needs while maintaining drift control.

Dual Fan Pattern Technology

The UR nozzle’s combo-jet design produces both flat-fan and air-induction spray patterns from a single tip. You can switch between standard coverage for calm conditions and drift-reducing mode when winds pick up. This dual functionality creates droplets ranging from 150-400 microns, giving you control over drift potential while maintaining coverage quality.

Easy Field Conversion

Converting between spray patterns takes seconds without removing the nozzle from your boom. You simply rotate the cap to switch from flat-fan to air-induction mode based on current wind conditions. This field flexibility eliminates the need to carry multiple nozzle types or stop spraying when conditions change unexpectedly.

Cost-Effective Solution

The UR nozzle costs 30% less than buying separate flat-fan and air-induction nozzles for your sprayer. You’ll save money on inventory while reducing the complexity of managing different nozzle types. The single-nozzle solution also means fewer spare parts to stock and maintain throughout the season.

Pros and Cons

Pros: Versatile dual-pattern design, quick field conversion, and cost savings compared to separate nozzle systems. Cons: Slightly lower drift reduction (70%) compared to dedicated air-induction nozzles, and the conversion mechanism requires regular cleaning to prevent sticking in field conditions.

Installation and Maintenance Tips for Drift Reducing Nozzles

Proper installation and consistent maintenance of your drift reducing nozzles will determine whether you achieve that promised 75-90% drift reduction or end up with expensive chemical waste.

Proper Installation Procedures

Install nozzles with the spray fan perpendicular to your travel direction. Check that each nozzle sits flush against the boom without gaps or tilting. Torque nozzle caps to manufacturer specifications – typically 15-25 ft-lbs – to prevent air leaks that compromise air induction performance. Verify nozzle spacing matches your target overlap percentage, usually 100% for even coverage.

Regular Cleaning and Maintenance

Clean air induction ports weekly during spray season using compressed air and soft brushes. Chemical residues clog these critical openings, reducing drift control effectiveness. Replace worn nozzle tips when spray patterns become uneven or flow rates drop 10% below specifications. Store nozzles in clean, dry conditions with protective caps to prevent contamination between seasons.

Troubleshooting Common Issues

Uneven spray patterns typically indicate clogged air ports or worn nozzle components. Check for consistent droplet formation – streaky or pulsing patterns mean internal damage requiring replacement. Monitor pressure fluctuations that affect droplet size consistency. Replace entire nozzle assemblies rather than individual components when drift reduction performance degrades below acceptable levels.

Best Practices for Using Drift Reducing Nozzles in Sensitive Areas

Proper nozzle selection is only half the battle – environmental conditions and application techniques determine whether you’ll achieve that promised 75-90% drift reduction.

Weather Condition Considerations

Wind speed matters most when you’re spraying near sensitive areas. You should never spray when winds exceed 10 mph, even with the best drift-reducing nozzles.

Temperature inversions create the worst drift conditions. These occur during calm mornings and evenings when cool air sits below warm air, trapping droplets and carrying them horizontally for miles. Check for inversions by observing smoke patterns – if smoke layers horizontally instead of rising, wait until conditions improve.

Application Timing Guidelines

Early morning applications between 6-10 AM offer the most stable atmospheric conditions for sensitive area spraying. Winds typically remain calm and temperature inversions break up as the sun rises.

Avoid midday applications when temperatures exceed 85°F. High temperatures increase droplet evaporation, making even large droplets shrink to drift-prone sizes before reaching your target. Evening applications after 6 PM often coincide with temperature inversions, increasing drift risk significantly.

Buffer Zone Requirements

Federal regulations require minimum 150-foot buffer zones from sensitive areas when using standard nozzles. Drift-reducing nozzles can reduce this requirement to 110 feet in many states, but check your local regulations first.

Water sources need the strictest protection – maintain at least 200 feet from streams, ponds, and wells regardless of nozzle type. Organic farms and bee yards require 300-foot buffers unless you’re using certified low-drift nozzles with documented 90% drift reduction rates.

Conclusion

Protecting sensitive areas from spray drift isn’t just about compliance—it’s about preserving your reputation and avoiding costly penalties. The four nozzles we’ve reviewed each offer proven drift reduction capabilities that can save you from expensive mistakes and regulatory headaches.

Your choice ultimately depends on your specific application needs and budget constraints. Whether you prioritize maximum drift reduction air-induction technology or need the versatility of multi-pattern systems you’ll find a solution that fits your operation.

Remember that even the best nozzle technology won’t perform without proper maintenance and favorable weather conditions. Combine these quality nozzles with smart application timing and you’ll achieve the drift control needed to spray confidently near sensitive areas while maintaining effective pest control results.

Frequently Asked Questions

What is spray drift and why is it a concern?

Spray drift occurs when pesticide droplets move away from the intended target area due to wind, evaporation, or improper application techniques. Fine droplets under 150 microns pose the highest drift risk, potentially causing crop damage, water contamination, and harm to beneficial insects. This can lead to costly lawsuits, regulatory violations, and penalties ranging from $1,000 to $50,000.

How much can drift-reducing nozzles reduce off-target movement?

Modern drift-reducing nozzles can significantly reduce off-target movement by 50-90% compared to standard nozzles. The exact reduction depends on the specific nozzle technology used, with air induction nozzles typically providing the highest drift reduction rates due to their ability to create larger, air-filled droplets that resist wind movement.

What droplet size is best for reducing drift while maintaining coverage?

Medium to coarse droplet sizes ranging from 200-400 microns strike the optimal balance between drift reduction and coverage quality. Droplets in this size range are large enough to resist wind drift but small enough to provide effective chemical deposition and uniform coverage across the target area.

What operating pressure should I use with drift-reducing nozzles?

Most drift-reducing nozzles operate effectively at lower pressures between 15-40 PSI. Lower operating pressures help produce larger droplets and reduce equipment wear. However, specific pressure ranges vary by nozzle model, so always consult manufacturer recommendations for optimal performance and droplet size control.

Which nozzle provides the highest drift reduction?

The TeeJet AI3070VS Air Induction Nozzle offers the highest drift reduction at up to 90% compared to standard nozzles. It features advanced air induction technology that creates larger, air-filled droplets while maintaining excellent coverage uniformity and consistent droplet size control across a 15-40 PSI operating range.

What are the key features to look for in drift-reducing nozzles?

Key features include air induction technology for creating larger droplets, droplet size control capabilities, appropriate pressure requirements (typically 15-40 PSI), and uniform spray distribution. Look for nozzles with a coefficient of variation (CV) rating below 10% for optimal coverage uniformity and consistent chemical deposition.

When should I avoid spraying to minimize drift?

Avoid spraying when wind speeds exceed 10 mph, during temperature inversions (typically early morning or evening), and in unstable atmospheric conditions. The best spraying conditions are early morning hours with stable weather, light winds (3-10 mph), and no temperature inversions present.

What buffer zones are required when spraying near sensitive areas?

Buffer zone requirements vary based on nozzle type and proximity to sensitive areas, as mandated by federal regulations. The specific distance depends on the application, chemical used, and environmental conditions. Always consult current EPA guidelines and local regulations, as buffer zones can range from 25 feet to several hundred feet.

How often should drift-reducing nozzles be cleaned and maintained?

Clean drift-reducing nozzles after every use or when performance degrades. Air induction nozzles require periodic cleaning of air ports to prevent clogging. Replace worn nozzles when spray patterns become uneven or when droplet size consistency decreases. Regular maintenance ensures optimal drift reduction performance and extends nozzle life.

Are drift-reducing nozzles compatible with all pesticides?

Most drift-reducing nozzles are compatible with various herbicides, fungicides, and insecticides. However, compatibility can vary by nozzle design and chemical formulation. Always check manufacturer specifications and pesticide labels for compatibility information before use to ensure optimal performance and avoid potential application issues.